Inventory Management for Competitive Advantage

Including a Practical and Effective Purchasing Strategy for Managers

- 262 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Inventory Management for Competitive Advantage

Including a Practical and Effective Purchasing Strategy for Managers

About this book

Smart, strategic inventory management delivers competitive advantage, yet Inventory Turn trends suggest that little seems to change. Sustainable improvement through increasing control of systems and processes generates savings that can, in turn, be invested in growth initiatives. Inventory is not something that just concerns planning, production and finance. By working to better understand and control their inventory-related processes, everyone can drive improvements that will harness inventory's potential to become a source of sustainable competitive advantage.

Unlike other guides to inventory management, this book is not only aimed at planners or inventory managers, but details the impact, both direct and indirect, that all functions have on inventory. It is rich in practical tools that can be clearly implemented, including a detailed purchasing strategy and guide to error management. It is also rich in best-practice cases that further show how to implement these methodologies in a real-world context.

This book is essential reading for any manager or executive looking to boost their organisation's competitive advantage, as well as students of inventory management, production and operations management.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

1

BACKGROUND

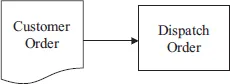

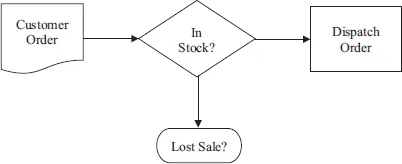

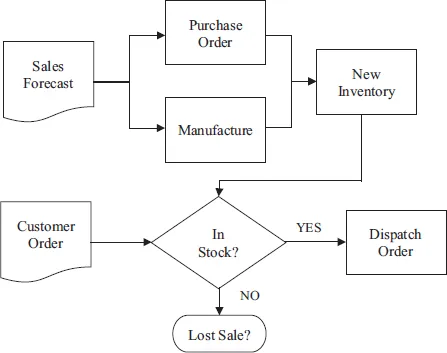

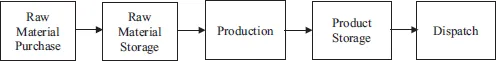

Inventory phases

Stable equilibrium

- Excess raw material purchase

- Damaged raw material inventory

- Minimum batch size or production run creating more product than required

- Production of rejected product

- Damaged product inventory

- Poor inventory rotation

Conflicting objectives

Table of contents

- Cover

- Half Title

- Title

- Copyright

- Dedication

- Contents

- Acknowledgements

- Preface

- Terms

- Introduction

- 1 Background

- 2 Finance

- 3 Planning

- 4 Production

- 5 Dispatch

- 6 Goods Inwards

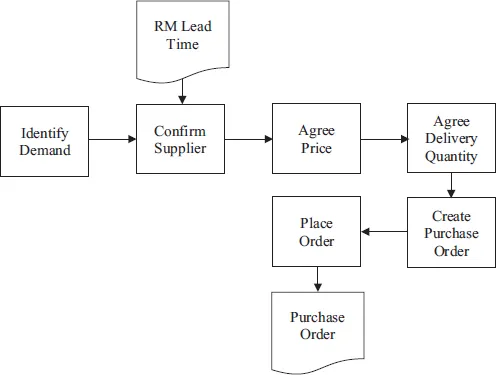

- 7 Purchasing

- 8 Sales

- 9 Technical Service

- 10 Customer Service

- 11 Marketing

- 12 Research and Development

- 13 Error management

- 14 Summary

- Appendix 1 Inventory count checklist

- Appendix 2 Analysis template

- Appendix 3 Safety Stock

- Appendix 4 Safety Stock review

- Appendix 5 Anticipated order pre-approval

- Appendix 6 Detailed production plan

- Appendix 7 Production briefing agenda

- Appendix 8 Shift handover form

- Appendix 9 Dispatch variance report

- Appendix 10 Standard selection list

- Appendix 11 Dispatch instructions template

- Appendix 12 Goods Inwards instructions template

- Appendix 13 Preferred purchase quantity approval

- Appendix 14 Manufacture without purchase order

- Appendix 15 Consignment inventory request

- Appendix 16 Consignment inventory administration

- Appendix 17 Customer trial checklist

- Appendix 18 Initial use checklist

- Appendix 19 Ongoing use checklist

- Appendix 20 Market research checklist

- Appendix 21 New raw material introduction

- Appendix 22 Formula and process change management

- Appendix 23 ECR segment attributes

- Index