![]()

Part I

Lean Demand-Driven Procurement: Overview

![]()

1

Introduction: Why You Need a Lean and Agile, Demand-Driven Supply Management Process

Lean thinking has expanded well beyond its origins in repetitive assembly line manufacturing to encompass process- and product-focused manufacturing. Recently, it has also been successfully applied to administrative, supply chain, and operations management functions in a variety of goods and services industries.

However, while there are many books, articles, and blogs written on the basics of the “supply” side of the supply chain (i.e. strategic sourcing, sourcing/procurement, and purchasing), there hasn’t been much written on those areas from a Lean perspective. This is quite surprising, considering not only that supply chain costs (primarily procurement and transportation), can range from 50 to 70% of sales, resulting in what is known as the “profit-leverage” effect (measured by the increase in profit obtained by a decrease in purchase spend), but also help drive downstream quality, productivity, and efficiency.

Many companies tend to place an inordinate emphasis on the traditional focus of reducing material costs instead of taking the more holistic approach of the Lean philosophy of continuous process improvement. Applying Lean principles to procurement and purchasing processes can identify non-traditional sources of waste, in some cases creating a paradigm shift that results in additional benefits to the entire supply chain.

This book takes a unique approach, in that it covers a combination of basic “supply management” concepts and processes (i.e. strategic sourcing, procurement, and purchasing) described in an easy-to-understand format, from a Lean perspective, using various process improvement tools, methodologies, best practices, examples, and cases. It focuses on ways to identify waste on the supply side through improved processes and in some cases, technology.

For the sake of clarity, we will define “procurement” (used in this book interchangeably with “sourcing”) as the activities involved in establishing fundamental requirements, activities such as market research and vendor evaluation, and negotiating contracts. In a broad sense, it also includes the purchasing activities required to order and receive goods.

“Purchasing,” on the other hand, is the specific process involved in ordering goods such as the request, approval, and creation of purchase orders and the receipt of goods.

Where to Look

If you were to ask someone who knew a bit about Lean thinking how they defined Lean procurement, they would probably say that it’s about increasing productivity for procurement staff so they can spend more time on value-added activities rather than administration. While that is certainly true, in this book we will extend the view to how it connects and interacts with other processes, functions, suppliers, and customers, as today, procurement plays an important role in improving the flow of information and materials throughout the entire supply chain.

It is important to establish best practice Lean procurement functions that go beyond contract negotiation and establish crucial operational requirements, utilizing strategic sourcing activities such as market research and vendor evaluation and integration.

Inventory management and sourcing supply chain decisions are directly linked to a company’s financial performance and can therefore affect a company’s cashflow and profitability.

A procurement organization needs to consider:

• The prevention of production disruptions due to inventory or material shortages, while remaining flexible to meet changes in customer demand or cope with market volatility.

• The trade-offs of inventory carrying costs and customer service levels.

• Optimal buying quantities that consider the trade-offs of inventory carrying cost and volume discounts.

• Moving from reactive to proactive procurement operations.

A Lean and Agile Procurement Process Is Required

Furthermore, in today’s global, dynamic economy, it is beneficial for companies to operate a supply chain, and supporting procurement process, that is both Lean and Agile. Using Lean and Agile in combination is known as having a hybrid supply chain strategy.

A hybrid supply chain strategy may be appropriate for a company attempting to become a “mass customizer”—producing progressively smaller batch sizes (sometimes as little as one item) specific to customers’ sometimes unique needs.

A Lean supply chain focuses on adding value for customers, while identifying and eliminating waste—anything that doesn’t add value for the customer. Being Agile and responsive, on the other hand, implies that your supply chain can handle unpredictability—and a constant stream of new, innovative products—with speed and flexibility.

An Agile strategy uses a wait-and-see approach to customer demand by not committing to the final product until actual demand becomes known (also referred to as postponement). For example, this might involve the subassembly of components into modules in a lower-cost process, with final assembly done close to the point of demand in order to localize the product.

An Agile supply chain must be responsive to actual demand, and capable of using information as a substitute (to some degree) for inventory through collaboration and integration with key customers and suppliers.

On some occasions, either an Agile or a Lean strategy might be appropriate for a supply chain. But many companies will probably face situations where a hybrid strategy is a better fit. If so, they need to carefully plan and execute the combined strategy with excellence, which is often easier said than done, because it involves a lot of moving parts. As in so many aspects of supply chain and operations management, there is more than one way to accomplish this goal.

One example of a company using a hybrid strategy in its supply chain is Zara, a Spanish fashion designer and retailer. Zara directly manufactures most of the products it designs and sells, and performs activities such as cutting, dyeing, labeling, and packaging in-house to gain economies of scale. A network of dedicated subcontractors performs other finishing operations that cannot be completed in-house.

As a result, Zara has a supply chain that is not only Agile and flexible, but incorporates many Lean characteristics into its processes.

Some semiconductor manufacturers incorporate a hybrid strategy using a flexible manufacturing and distribution model. Subcontractors perform distinct manufacturing processes at separate physical locations. This hybrid approach taps a virtual network of manufacturing partners and requires responsive, flexible, and information-driven sourcing, manufacturing, and distribution functions—in many ways, the opposite of Zara’s strategy of shifting processes in-house.

Many organizations can find some form of hybrid supply chain that works well for them. In today’s ever-changing, volatile, and competitive global economy, it may often be in a company’s best interest to operate a supply chain that is both Lean and Agile (Myerson, 2014).

Procurement Focus Areas (The Eight Wastes of Lean)

In general, many Lean manufacturing tools and methodologies can be applied in all areas of the supply chain to improve product quality, reduce lead-time, and reduce working capital. Specifically, waste in procurement processes can also be identified and reduced in the same way as waste in manufacturing, creating both tremendous savings and process improvements.

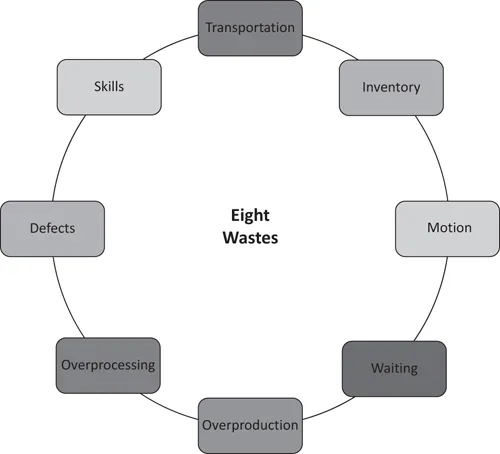

Examples of waste or non-value-added activities in procurement and entire supply chain organizations can be found in all eight categories of waste (easily remembered by using the name “TIM WOODS”; Figure 1.1).

FIGURE 1.1

The Eight Wastes of Lean.

You can zero in on these opportunities in procurement by focusing on the eight wastes below:

• Transportation: Excess paperwork and transporting materials and component inventory around a facility more than would be otherwise needed.

• Inventory: Ordering inventory or services early or in excess due to poor visibility or inaccurate information in material requirements planning (...