Make Your Business a Lean Business

How to Create Enduring Market Leadership

- 327 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Make Your Business a Lean Business

How to Create Enduring Market Leadership

About this book

Make Your Business a Lean Business is a written by business leaders for business leaders as a how-to guide to building enduring market leadership. Written by authors with more than 60 years' experience applying Lean to operations and businesses, this book will allow readers to understand Lean principles and apply practices to transform their business. It also

- Shows readers how to transform their business to a Lean business using Lean philosophy, values, practice, and tools

- Is a comprehensive Lean Enterprise Operational Management System implementation guide that defines the Lean Enterprise Business Model

- Uses personal author experiences throughout the book to illuminate and reinforce concepts and practices

- Provides insights and a roadmap so executives can take immediate action to start building a Lean business

Readers will be able follow a logical path aligning their business from strategy to detailed activity, thereby engaging their entire organization in becoming more competitive. It is the only true enterprise book about applying Lean to the entire business, and it provides business leaders with the understanding, approach, and tools to plan, align, and transform their business starting with their core business value proposition, business planning, disciplined goal and resource alignment, and implementation management.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

1The Lean Enterprise Operational Management System Overview

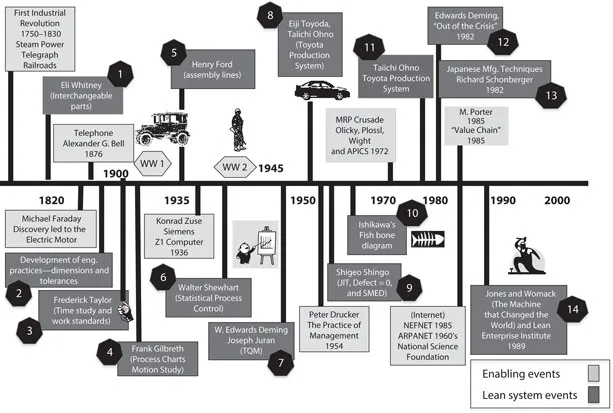

Origin and Evolution of Lean

The Story

- The first major contribution to Lean manufacturing practice was Eli Whitney’s innovation (1765–1825). An American inventor, pioneer, mechanical engineer, and manufacturer, Eli Whitney is best remembered for his cotton gin invention. He also affected U.S. industrial development by manufacturing government muskets in 1799. He translated interchangeable parts concepts into a manufacturing system, giving birth to American mass-production systems. Whitney saw an opportunity to become rich and increase Southern prosperity if a machine to clean seeds from cotton could be invented. He set to work at once and within days had drawn a sketch to explain his idea; 10 days later, he constructed a crude model that separated fiber from seed. His gin, however, was a minor accomplishment compared to perfecting interchangeable parts. Whitney developed a musket design with interchangeable parts after taking a U.S. Army contract to manufacture 10,000 muskets at a price of under $14.00 each.

- Over the next 100 years, manufacturers primarily focused on specific engineering conventions, practices, and process technologies. During this time, our engineering drawing systems, modern machine tools, and large-scale processes, such as the Bessemer process for making steel, were all developed. Few people concerned themselves with movement of products from one discrete process to another or with logistics systems from suppliers, within factories, and to customers. No one was asking questions such as

- What happens between processes?

- How should multiple processes be arranged within a factory?

- How does the chain of processes function as a system?

- How does each worker’s task relate to other workers?

This began to change in the late 1890s when Industrial Engineering was developing as an important technology discipline. - The first and best-known industrial engineer is Frederick Winslow Taylor, the father of scientific management. He was born into an upper class, liberal Philadelphia family on March 20, 1865 and died in 1915. Taylor was a compulsive adolescent and was always counting and measuring things to figure out a better way of doing something. At age 12, he invented a harness so he could not sleep on his back, hoping to avoid having nightmares. At age 25, Taylor earned an engineering degree at Stevens Institute of Technology in New Jersey while employed full time. He had a degree from an exclusive university and excelled in math and sports, but chose to work as a machinist and pattern maker in Philadelphia for Enterprise Hydraulic Works. After his hydraulic works plant apprenticeship, he became a shop floor operator at Midvale Steel Company. He started as a shop clerk and quickly progressed through positions of machinist, foreman, maintenance foreman, chief draftsman, director of research, and finally chief engineer. While working there, he introduced a piecework compensation plan at Midvale Steel Company’s factory. He closely watched how work was done and measured the quantity produced to find the most efficient way to perform specific tasks. Taylor believed that finding the right challenge for each person and paying him well for increased output was key to improved productivity. At Midvale, he used time studies to set daily production quotas. Incentives would be paid to those reaching their daily goal. Those who did not reach their goal received much lower pay rates. Taylor doubled productivity using time study, systematic controls and tools, functional foremanship, and a new wage scheme, which paid shop floor operators for production output rather than for hours worked. Taylor began to analyze individual workers using work analysis, time study, and standardized work methods. His scientific management approach made a significant contribution by applying science to management, but that success was limited because he never recognized the importance of human factors and behavioral sciences to productivity.

- Frank Bunker Gilbreth was born in 1868 in Fairfield, Maine and died in 1924. Over the course of his career, he was a bricklayer, building contractor, and engineering manager. He was a member of ASME and the Taylor Society, and a lecturer at Purdue University. His spouse Lillian Evelyn Moller-Gilbreth was born in 1878 in Oakland, California and died in 1972. She graduated with BA and MA degrees from the University of California and went on to earn a PhD from Brown University. She was a member of ASME and also lectured at Purdue University. Frank and Lillian Gilbreth were associates of Frederick Taylor. They had experience in manufacturing industries, which led to an interest in work standardization and methods study. Frank worked at construction sites and noticed that no two bricklayers used identical methods or sets of motions. He improved existing methods by eliminating all wasted motions and raised output from 1000 to 2700 bricks per day. From these studies, Gilbreth developed laws of human motion, which evolved into principles of motion economy. They coined the phrase “motion study” to cover their field of research, thus distinguishing it from those involved in “time study.” The second method developed was process charts, which focuses attention on all work elements, including those non-value-added elements, with the goal of optimizing operator motion and method. Gilbreth’s two methodologies were important contributions to industrial engineering’s body of knowledge.

- Henry Ford was born in 1863 in Wayne County, Michigan and died in 1947. He was a pioneering automotive engineer who held many patents on automotive mechanisms. He served as vice president of the Society of Automotive Engineers, which was founded in 1905 to standardize U.S. automotive parts. Ford is best remembered for devising moving factory assembly lines and a completely integrated supply chain. His approach to production revolutionized manufacturing industries by greatly increasing productivity and quality of products. Ford showed an early interest in mechanics, constructing his first steam engine at 15 years of age. In 1893, he built his first internal combustion engine, a small one-cylinder gasoline model, and in 1896, he built an automobile. In 1903, Ford established Ford Motor Company and served as the president from 1906 to 1919 and again from 1943 to 1945. Around 1910, Ford and his right-hand man, Charles E. Sorensen, fashio...

Table of contents

- Cover

- Advance Praise

- Half Title Page

- Title Page

- Copyright Page

- Contents

- Authors

- Introduction

- Chapter 1 The Lean Enterprise Operational Management System Overview

- Chapter 2 Why Lean Enterprise?

- Chapter 3 Business Strategy-Driven Lean Enterprise

- Chapter 4 Engaging Leadership and Preparing the Culture Change Plan

- Chapter 5 Lean Enterprise Transformation Preparation and Launch

- Chapter 6 Lean Enterprise Operational Management System Factory Operations Implementation

- Chapter 7 Applying the LEOMS to Enterprise Supply Chains

- Chapter 8 LEOMS Application to Transactional Processes

- Appendix I Book Resources for Practitioners

- Appendix II Taiichi Ohno Core Lean

- Appendix III Cameron and Quinn’s Culture Change Methodology Value

- Appendix IV Benchmark Data Sources

- Appendix V Validation of the LEOMS’s Value

- Index