eBook - ePub

Integrated Process and Fixture Planning

Theory and Practice

- 258 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Integrated Process and Fixture Planning

Theory and Practice

About this book

Fixtures are used in manufacturing to secure working devices. They help insure conformity, accuracy, efficiency, and interchangeability; their reliability is crucial. This book introduces and implements a new methodology for more flexible fixture design and manufacturing processes, and develops the supporting technologies for automation and fixture planning using object oriented platforms. It also presents an integrated solution with Computer Aided Design (CAD) applications.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Integrated Process and Fixture Planning by Awais Ahmad Khan,Emad Abouel Nasr,Abdulrahman Al-Ahmari,Syed Hammad Mian in PDF and/or ePUB format, as well as other popular books in Business & Industrial Engineering. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Computer-Based Design and Features

1.1 Introduction

Manufacturing industries have become an integral part of any society. They are required in managing national security, defense, as well as they impact the standard of living and improve the economy of the country [1]. The advances in flexible automation technologies, such as computer numerical controlled (CNC) machines, high-speed networking, and e-business, have drastically improved the productivity of the manufacturing industries in recent times. A higher quality, better performance, and time-on delivery in addition to reasonable cost are very important factors in order to thrive and sustain in a highly competitive global market. As a result, the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) tools have increased in product and process design in the last decade or so. As the power of computing continues to increase, the use of CAD/CAM has become ubiquitous, extending to the smallest shop and the most remote countries in the world [2]. Traditionally, design and manufacturing are considered as two separate entities in the product development cycle. There is no communication between the two entities, that is, no information flow, since they are carried out by two different sets of people [3]. The detailed design in the form of annotated engineering drawing is passed on to the manufacturing personnel to get the end product. Most often, it takes a number of runs between the two groups until they reach a satisfactory result [4]. This results in a slow and costly process. Therefore, it is very important for manufacturing industries to implement novel techniques in different phases of the product development cycle. Hence, to accomplish the task of efficient and cost-effective production, Boyer et al. [5] emphasized the importance of integration between the design and manufacturing processes. The seamless integration between different stages provides a provision of real-time response to changes in design, setup planning, fixture design, production scheduling, and so on [6]. In fact, the primary objective of the integration of CAD and CAM is to assist the design, modification, analysis, and manufacture of parts automatically and efficiently within the specified time [7].

Computer Integrated Manufacturing (CIM) has been recognized as one of the promising approaches to solve the problem of the conventional design-manufacturing cycle [8]. By integration of the design and manufacturing activities, that is, CAD and CAM, the product can be evaluated at the early stage of the development plan. During the design work, the design engineer can be advised simultaneously on the functional analysis and the performance of his design, which guarantees the final design of the product to be feasible from economic and manufacturing consideration, and as such, achieving better product quality, lower production cost, and higher productivity.

The development of flexible manufacturing systems (FMS) and associated user-friendly CAD/CAM systems has facilitated the subsequent development of far higher levels of automation within manufacturing processes [9]. The FMS should be able to produce a set of machined parts with the minimum manual intervention. In spite of the considerable amount of effort, resources and financial investment, there are still some technical operations that cannot be performed satisfactorily without the intervention of a skilled and knowledgeable operator, particularly when small- and medium-sized batches of a product need to be produced. One of the most critical problems that occurs in such situations is related to the fixture design process. The accuracy and reliability of the fixture design process have a significant influence on the accuracy of the subsequent manufacturing operations.

Fixtures are important in both, the traditional manufacturing and modern FMS. They directly affect the machining quality, productivity, and cost of products [10]. The time spent on designing and fabricating fixtures significantly contributes to the production cycle in improving current products and developing new products. Therefore, great attention has to be paid in studying the fixturing design process in manufacturing. The manual fixture design requires the consideration of a number of factors like primary requirements of the design, demands to be achieved, use of automated and semi-automated clamping devices, safe operation, and so on. The application of these fundamental principles to an individual fixture design depends primarily on the designer’s experience. The collection and representation of this knowledge from the designer’s experience is a crucial part of Computer-Aided Fixture Design (CAFD).

Even though several approaches have been developed for fixture design and analysis, still the implementation of these techniques in the industry is somewhat difficult. The limitations in implementation are due to the lack of practical solutions during the fixture assembly. Although, fixtures can be designed using CAD functions, but the lack of tools and a systematic approach to evaluate the design process have often lead to trial-and-error strategies. The manual fixture design depends solely on the designer experience. Such issues create limitations in the advancement of the manufacturing industry. The trends in the manufacturing industry toward FMS demand the development of technology and strategies for automatic generation of an efficient fixture design process. To address these issues, there is a need to employ practical approaches in fixture assembly and integrate various phases of the automatic CAFD system.

1.2 Computer-Aided Design and Computer-Aided Manufacturing Integration

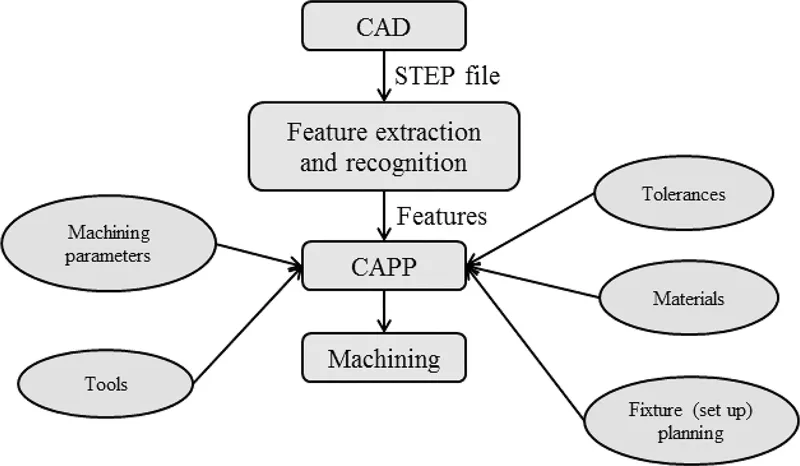

The integration between CAD and CAM can significantly reduce the time between design and manufacturing as well as improve the performance of production processes. The information provided in design comprises dimensional (geometric shape and features) and inspection specifications (tolerance, surface finish, and etc.). CAD and CAM technologies are intended to integrate CAD, computer-aided process planning (CAPP), and CAM into one platform that allows the user to design, plan, and control the manufacturing of products while automating as many activities as possible. The CAD/CAM integration can be achieved through the following steps: product design, drafting and documentation, production planning and scheduling, and finally, manufacturing [11]. CAD refers to the application of computer technology in design while CAD/CAM applications are used both to design a product and program manufacturing processes. CAM software utilizes the models developed in the CAD software to generate tool paths, which in turn transform the designs into physical parts.

The integration of CAD functions with CAM applications gives the acronym CAD/CAM. The CAD/CAM represents the integration between design and manufacturing activities using computer systems. The type of manufacturing operation depends upon the specific design. As a consequence, the combining of CAD with CAM in CAD/CAM generates a direct link between product design and product manufacture that can be utilized in the production system. In a perfect CAD/CAM system, it is possible to take the design specification of the product from the CAD database and transform it automatically into a process plan for fabricating the product.

Presently, the trend in the market requires companies to be competitive in terms of low cost, high quality, and shorter delivery times. The requirements for sustainable manufacturing can effectively be achieved through the integration of CAD and CAM systems as shown in Figure 1.1. The proper integration of CAD and CAM systems can help companies to survive the increasingly stringent demands of productivity and quality in the design and production [13]. The design process has to be carried out in synchronization with knowledge of the nature of the production process. This is due to the fact that the designer must have the prior knowledge of the properties of the machining materials, various machining techniques, and the production rate, and so on. Therefore, the integration between design and manufacture can provide potential benefits to the manufacturing industries.

Figure 1.1 CAD/CAM integration. (Saaski, J. et al., Integration of CAD, CAM and NC with Step-NC, VTT Information Service, Espoo, Finland, 2005.)

1.2.1 The Role of Computer-Aided Design/Computer-Aided Manufacturing in Manufacturing

The integration of CAD and CAM systems in the broad sense can be referred to as simultaneous or concurrent engineering [14]. Concurrent engineering was adopted by the Ford Motor Engine Division, B. F. Goodrich, and Cannondale in the early 1990s. Ford’s Engine Division integrated all the production and design systems into a single database that could be accessed by engineers, designers, as well as consumers. In its production of wheels and carbon braking systems for Boeing’s new 777, B. F. Goodrich developed a system that linked all relevant departments, including planning, purchasing, design, manufacturing, and quality control. Moreover, Cannondale affirmed that “CAD/CAM technologies helped them to manufacture five times as many bicycles per year with the same floor space.” CAD/CAM also enabled the firm to redesign 90–95 percent of its 37 models each year.

The effective implementation of CAD/CAM systems offers manufacturers a number of benefits such as: lower design cost, reduced production cycle time, increased productivity, and improved information flow [15]. With the implementation of CAD/CAM systems, the productivity increases with the simultaneous decrease in design and the production costs. As a result, valuable organization time can be utilized proactively in managing customer demands and other value-added activities. The integrated CAD/CAM systems are helpful to manufacturing industries in the following ways [16]:

■ Using CAD/CAM technology, kinematic and dynamic analysis can be used to analyze complex motions of mechanisms as well as carry out tolerance analysis.

■ Many uncertainties which can result in time delay, rework, or production of defective parts in CNC machining, plastic injection molding, casting, forging, or welding, and so on, can be eliminated through simulation in CAD/CAM systems.

■ CAD/CAM systems are useful to produce a variety of customized products. They introduce flexibility in the manufacturing process.

Since 1970, there has been a rapid rise in the use of CAD/CAM technologies, primarily due to the development of high-performance computer systems. The CAD/CAM ...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Preface

- Description of Book

- Acknowledgment

- Authors

- 1 Computer-Based Design and Features

- 2 Methodologies of Feature Representations

- 3 Feature Extraction Techniques

- 4 Data Transfer in CAD/CAM Systems

- 5 Automatic Feature Recognition

- 6 Computer-Aided Process Planning

- 7 Integration System for Fixture Layout Design

- 8 Application of an Integrated System for Process and Fixture Planning

- Index