eBook - ePub

Re-Engineering the Manufacturing System

Applying the Theory of Constraints, Second Edition

- 384 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Re-Engineering the Manufacturing System

Applying the Theory of Constraints, Second Edition

About this book

An information systems trailblazer in the domains of decision support and factory and supply chain synchronization, the second edition of Re-Engineering the Manufacturing System stays true to its title, once again bestowing uniquely straightforward instructions for designing, installing, and operating manufacturing information systems. This updated and expanded source takes care to clarify the often blurred concepts of synchronization and optimization and offers implementation advice from four discrete angles to yield better bottom-line results. It shows how to exploit an information system, rolling ERP system implementation into the TOC framework to promote profit materialization.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Re-Engineering the Manufacturing System by Robert E. Stein in PDF and/or ePUB format, as well as other popular books in Commerce & Opérations. We have over one million books available in our catalogue for you to explore.

Information

Topic

CommerceSubtopic

Opérations1

An Introduction

This chapter offers a brief history of the manufacturing information system, introduces the possibility that an improved methodology is available, and lays the groundwork for what is to follow.

I. CHAPTER OBJECTIVES

- To provide an overview for this book

- To lay a historical foundation

II. THE ADVENT OF THE TRADITIONAL SYSTEM

In 1974 Joseph Orlicky documented in his book Material Requirements Planning what had become one of the biggest changes to American manufacturing since the Industrial Revolution. Orlicky presented in intricate detail the design, interface, and calculation issues for what was called the manufacturing information system.

The advent of the computer and its ability to store and manipulate large volumes of data made it possible to create demand for upper level finished goods items, drive demand for lower level assemblies and raw material parts, and schedule the shop floor. For an industry that had been planning every part based on individual usage rates this was a major step forward.

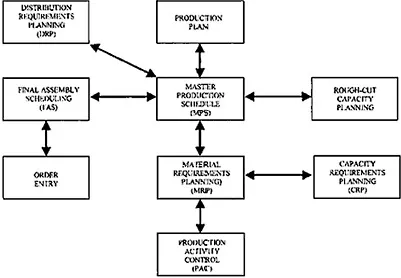

While he was not alone in this change, his book would become one of the most read in the American Production and Inventory Control Society (APICS) library for years to come. Oliver Wight and other pioneers in the field had also begun this documentation process. Each had been involved for some time in the creation of these systems. During the late 1960s and early 1970s, as these systems became reality, companies would see an opportunity to mainstream the computer system into American business. By the end of the 1970s and early 1980s the processes of master production scheduling, material requirements planning, capacity requirements planning, and shop floor control became commonplace. The closed loop system (Fig.1) became the most recognized graphic of the manufacturing systems industry.

The accepted technology had become so ingrained in industry, software companies, and consulting organizations as well as at the university level that it soon became very difficult to make any significant changes. Those changes that did occur were simply built on top of the assumptions upon which the original systems were designed.

Hampering any efforts to create improvements in the technology were the millions of dollars invested to create the software that would run this nation’s economy. Once written, manufacturing systems became not just software, but an investment that had to be protected by those who wrote or bought them. And, once learned by the user, this knowledge became job security. The slowness of the acceptance of techniques like just-in-time manufacturing or the Theory of Constraints (TOC) is evidence of the difficulties that had to be overcome in implementing new methodologies. Possibly the greatest problem to overcome can be summed up in a statement uttered by the head of manufacturing consulting for a major U.S. corporation, “It doesn’t matter whether you’re right or wrong this is what General Motors wants.” There is a tremendous amount of money to be made in the consulting industry in this country. For the benefit of the uninitiated it must be understood that being right isn’t necessarily the goal.

Figure 1 The closed loop system.

It was never a secret that there might be problems with the technology. In Orlicky’s book, now 20 years old, pages 46–48 provide some insight into the conflicts that existed at the time and are made very clear. Material requirements planning (MRP) was known to be “capacity insensitive.” However, the benefits so far outweighed the problems inherent in the order, launch, and expedite system commonly known as EOQ-ROP, or economic order quantity and reorder point, that the problems were ignored. At least for a while. The advent of finite capacity planning seemingly made it possible to now synchronize the way in which raw material was ordered with the way it was to be consumed by the resources and the market. Unfortunately the problems involved in attempting to accomplish this task were based upon the assumptions of the original system, making it virtually impossible to do so effectively.

Two issues that greatly hampered the creation of an effective system were cost accounting and a complete lack of knowledge of the physical laws that govern the manufacturing environment. The objective of the original system was to use the computer’s calculating abilities to time phase material requirements. However, to do this correctly meant that the system must resemble reality. And this is where things were done that made today’s manufacturing systems much less effective than they could be.

III. EXPLORING A DIFFERENT APPROACH

In the mid- to late 1970s Dr. Eli Goldratt, who had a background in physics, approached the information system from a totally different perspective. His observations, unfettered by the traditional thought process, resulted in his solving some very interesting problems and creating a technology that has proved to be far superior to the traditional manufacturing system. In his books The Goal (1992), The Race (1986), and The Haystack Syndrome (1990) and in classes at the Goldratt Institute, Dr. Goldratt presented a totally new way of looking at information as being the answer to the question asked. While this seems a trivial issue and is just common sense, if you get the question wrong or do not know how to answer it, you cannot begin to build the information system. This is where the fun begins. The questions as well as the answers are totally different than what had been taught for the last 50 years. With this in mind, how could anyone be expected to build the information system?

A. Providing the Key

It is very clear that a manufacturing system is not just a tool for planning material and scheduling the factory. It is an integral part of the five steps of improvement for the “throughput environment” as defined in The Haystack Syndrome and in The Theory of Constraints: Applications in Quality and Manufacturing (1997). The key issue that defines the effectiveness of the information system is how well it supports the TOC principles of

- Identifying the constraint

- Exploiting the constraint

- Subordinating the remaining resources

- Elevating the constraint

- Repeating the process

It is this sequence of steps that literally defines what an information system must do. Following them to their logical conclusions means that a system must aid in the identification, exploitation, and elevation of the constraint and with the subordination of the remaining resources. For this to occur means that the logic of the system must be very different than it is in the traditional system.

In The Haystack Syndrome, Dr. Goldratt also defines the structure of the information system. He establishes three separate segments along with justification for each. These segments include

- What if

- Control

- Schedule

His objective was to create a system which can help in answering questions, or to play the “what if” game. To support the “what if” there must be a “schedule” so that the physical laws governing the process can be addressed, and there must be a “control” so that problems that may arise can be addressed before they impact the schedule. This whole concept will be addressed in Chapter 3.

IV. AN OVERVIEW OF THIS BOOK

The remaining chapters of this book are dedicated to presenting the problems associated with the traditional system’s ability to support the five steps based on the TOC principles and to present, in detail, the solutions provided by the Theory of Constraints. The objective is to provide enough background as well as detailed information to allow industry to begin the process of redefining the information system.

It represents a tremendous change in the distinction of what an information system is and what it should do and lays the groundwork for the design of the next generation of systems, including

- Design

- Focusing mechanisms

- Processing logic

- Structure

The objective here is not to eliminate the MRP II system but to change it so that it will be more in line with the goal of the company. MRP II has created a great data system upon which to draw. How to use these data to implement the five steps is another issue. There must be a change.

A. Chapter Topics

- Chapter 2: Visiting the Traditional System is a general over-view of the problems associated with the traditional manufacturing system. The traditional system presents some very serious problems that must be overcome before it can really be called an information system.

- Chapter 3: Synchronization Versus Optimization. The recent introduction of advance planning and scheduling systems and supply chain management systems has only served to further confuse the market as to what is necessary. Chapter 3 presents a comparison between systems that serve to optimize and those that attempt to synchronize and shows why synchronization is a preferred solution.

- Chapter 4: Establishing the Characteristics of an Information System addresses from a conceptual perspective what an information system should do and how it should be organized. This is the first step in building a system that is based on reality.

- Chapter 5: Defining the Structure provides a global view of how the information system is structured. It puts every segment of the system into place and defines the interfaces between the various processes, including input and output.

- Chapter 6: Identifying the Constraint deals with the intricate details of how the system identifies the constraint, including processing logic.

- Chapter 7: Exploitation. It is not enough to identify the constraint. It governs the amount of money a company can make. It must be exploited for every dollar, yen, or pound that can be gained. Chapter 7 presents the processing logic for the exploitation phase.

- Chapter 8: Subordination. Once the constraint has been exploited, all the remaining resources must give the constraint what it needs and nothing more. Chapter 8 details the subordination logic.

- Chapter 9: Buffer Management. The system must be protected from those things that can and will go wrong. Chapter 9 presents the logic of the buffering process and buffer management.

- Chapter 10: Supporting the Decision Process. Once a complete definition of an information system has been made, how then should it be used to maximize the creation of throughput? By aiding in the process of answering specific questions, such as what lot size should be used, should a certain product be obtained from internal or external resources, and what price should I accept for a given product, the system can provide information that will make a difference.

- Chapter 11: Making Strategic Decisions. How and where a company should grow is important. One of the most significant uses of the information system i...

Table of contents

- COVER PAGE

- TITLE PAGE

- COPYRIGHT PAGE

- FOREWORD TO THE SECOND EDITION

- FOREWORD TO THE FIRST EDITION

- PREFACE TO THE SECOND EDITION

- PREFACE TO THE FIRST EDITION

- 1. AN INTRODUCTION

- 2. VISITING THE TRADITIONAL SYSTEM

- 3. SYNCHRONIZATION VERSUS OPTIMIZATION

- 4. ESTABLISHING THE CHARACTERISTICS OF AN INFORMATION SYSTEM

- 5. DEFINING THE STRUCTURE

- 6. IDENTIFYING THE CONSTRAINT

- 7. EXPLOITATION

- 8. SUBORDINATION

- 9. BUFFER MANAGEMENT

- 10. SUPPORTING THE DECISION PROCESS

- 11. MAKING STRATEGIC DECISIONS

- 12. MODIFYING THE CURRENT SYSTEM

- 13. IMPLEMENTING A TOC-BASED INFORMATION SYSTEM

- 14. IMPLEMENTING AN ERP SYSTEM TO IMPROVE PROFIT

- 15. CRITICAL CHAIN PROJECT MANAGEMENT

- 16. SCHEDULING THE MULTIPROJECT ENVIRONMENT

- APPENDIX: ERP IMPLEMENTATION AT ABC COMPANY

- GLOSSARY OF TOC TERMS

- BIBLIOGRAPHY