eBook - ePub

Condition Monitoring and Faults Diagnosis of Induction Motors

Electrical Signature Analysis

- 150 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Condition Monitoring and Faults Diagnosis of Induction Motors

Electrical Signature Analysis

About this book

The book covers various issues related to machinery condition monitoring, signal processing and conditioning, instrumentation and measurements, faults for induction motors failures, new trends in condition monitoring, and the fault identification process using motor currents electrical signature analysis. It aims to present a new non-invasive and non-intrusive condition monitoring system, which has the capability to detect various defects in induction motor at incipient stages within an arbitrary noise conditions. The performance of the developed system has been analyzed theoretically and experimentally under various loading conditions of the motor.

-

- Covers current and new approaches applied to fault diagnosis and condition monitoring.

-

- Integrates concepts and practical implementation of electrical signature analysis.

-

- Utilizes LabVIEW tool for condition monitoring problems.

-

- Incorporates real-world case studies.

-

- Paves way a technology potentially for prescriptive maintenance via IIoT.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Condition Monitoring and Faults Diagnosis of Induction Motors by Nordin Saad,Muhammad Irfan,Rosdiazli Ibrahim in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Electrical Engineering & Telecommunications. We have over one million books available in our catalogue for you to explore.

Information

Edition

11Introduction to Condition Monitoring of Electrical Machines

Several new technological advancements have allowed for the start of the investigation of the development of condition monitoring and faults diagnosis of induction motor systems from a noninvasive perspective. As an introduction, this chapter discusses the importance of induction motors in industry and why the prevention of unscheduled downtime is significant. This is followed by an explanation on machine maintenance and a brief description of various kinds of the possible motor faults and of condition monitoring techniques. An overview on development of the various types of condition monitoring and a brief survey of the subject are presented. A brief summary on the contents of the succeeding chapters are also provided.

1.1Background

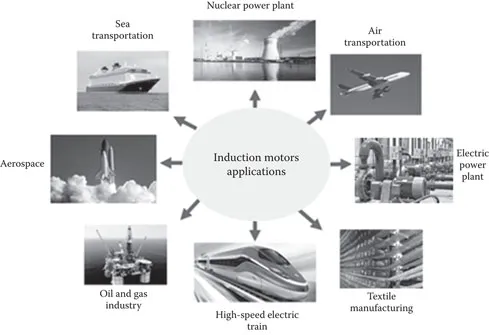

The type of motor most often utilized in industries worldwide is the induction motor. Induction motors make up 95% of the prime movers and utilize up to 40–50% of all the electric energy generated [1]. As shown in Figure 1.1, induction motors have been used in various applications, such as in the petroleum industry, chemical processing plants, nuclear power plants, paper mills, water cooling systems, and the mining industry. Induction motors have also been used in more general situations, such as with compressors, pumps, crushers, fans, lifts, air conditioners, machine tools, tractions, robotics, etc.

Figure 1.1Applications of induction motors.

Although induction motors are very dependable with low failure rates and require only basic maintenance, they, like other kinds of motors, sometimes break down and fail [2]. The unexpected breakdowns of the motors cause a great deal of unacceptable production loss. These breakdowns are certainly unacceptable in the application of induction motors, which are vital for any industry.

Consequently, detecting initial failures and replacing damaged parts, according to schedules, will prevent the problems of unexpected breakdowns of the machines [3]. The prevention of unscheduled downtime for electrical drive systems has been the goal of every industry, as this would help in reducing the costs associated with maintenance.

Notably, more than 50% of operating cost in manufacturing and processing plants is related to maintenance. Consequently, this is a major area of concern in industries. The researchers are constantly looking for new techniques that can lower the cost of maintenance and reduce the possibility of unexpected breakdowns.

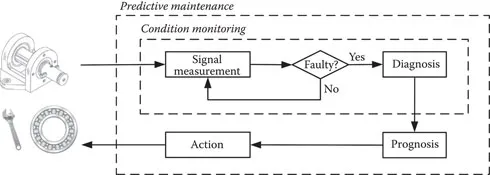

In general, the three methods for machine maintenance are classified as scheduled replacement, scheduled maintenance, and condition-based maintenance (CBM). On the one hand, with scheduled replacement, the replacement of machine parts is conducted on a regular basis. It is a very simple and easy method but proves to be very expensive. On the other hand, with scheduled maintenance, the checking and/or overhauling of the equipment has to be done on a regular basis. Scheduled maintenance is the method typically used, as it is less expensive than the scheduled replacement technique. In CBM, the condition of a machine is determined by taking measurements using a sensor. By this method, the time periods between maintenance can be increased, and the machines can be monitored continuously so that maintenance can be scheduled as needed. Condition monitoring (CM) is a technique that serves the CBM. It is an effective type of predictive maintenance (PM). The main steps involved in PM are shown in Figure 1.2.

Figure 1.2Activities in PM.

Normally, the CM maintenance process would be monitoring the specific parameters, like vibration, overheating, and overcurrent of equipment, for early signs of failure, as well as to forecast maintenance need before rigorous failure and estimate the machines’ overall health. This could be achieved with visual inspection or with a sophisticated intelligent diagnosis system. It embraces the life mechanism of the machine parts, the different data acquisition methods, and exploitation of the data to forecast the trends. CM is mainly appropriate for continuous process plants where breakdowns can be very costly. Before CM, time-based maintenance (TBM) was the technique served for preventive maintenance. In TBM method, maintenance is performed on predefined running hours of equipment, without the information of the current conditions of the machine. This causes wastage of manpower, time, and money. As maintenance must be performed offline, this causes many unnecessary shutdowns. However, unpredicted breakdowns may still occur in the intervals.

The methods of CM are categorized into two primary classifications, namely the offline tests and the online tests. The offline tests are performed by isolating the machine from main AC power supply. Although this is a comprehensive approach, sometimes it causes unnecessary shutdowns of machines. Alternatively, the sensors installed on the machine are used to detect faults through online CM and fault diagnosis of induction motors while they are operating. The online tests cause fewer disturbances than the offline tests, but the results produced from online tests are more complicated and their interpretation is more difficult than that of the offline tests.

Over the past two decades, there has been an abundance of research done in the area of CM, and several techniques have been developed for diagnosing the problems in induction motors. For detection of the various faults usually affecting machines, several techniques have been proposed and used successfully [4–6]. However, a good understanding of the mechanical and electrical properties of the machine in healthy and faulty conditions significantly influences the accuracy and reliability of the online CM methods.

Online CM techniques can be classified into two categories: (1) the classical method and (2) the digital method [7]. In the classical method, electromechanical devices are used to protect the motor. The electromechanical devices are expensive and less efficient. They have a very slow response and are not as reliable as some of the devices that have a shorter lifetime than the motor itself. The digital method is the latest method for CM, and it involves the use of integrated circuits, microcontrollers, microprocessors, and programmable logic controllers.

1.2Condition Monitoring

In recent years, the use of innovative analysis methods, along with the aid of systems for acquiring and processing progressive computerized data, has brought forth new areas in the study of CM for induction motors. One of the leading research topics for energy and electrical industries today is the development of the new CM system for induction motors. CM has prolonged the lifetime of electrical machinery and has minimized the possibility of disastrous machine failure. Computer and transducer technologies, along with advanced signal processing methods, have resulted in the ability to apply CM systems in a more effective manner [8,9]. As a result, CM has been more reliable with lower maintenance cost. Another important issue is that, during the maintenance period, the data regarding the status of the machinery should be obtained online so that disastrous machinery failure can be more effectively reduced. Related to this study, a baseline study of faulty and healthy motors has been conducted, which took to analyze the localized and distributed bearings and gears faults. Many methods have been developed that support the development of the CM system. However, these methods typically use specialized and expensive sensors [10–24]. It would be possible to explore a more effective, and less costly, method for monitoring and analyzing faults by utilizing the motor stator current signals. CBM provides the current status of machines and indicates clearly where and what type of maintenance is required. The aim is to achieve optimal use of machine parts and guarantees that breakdowns will not occur unexpectedly. It will be the most favorable ...

Table of contents

- Cover

- Half Title Page

- Title Page

- Copyright Page

- Dedication

- Contents

- Preface

- Author

- List of Abbreviations

- Nomenclatures

- Chapter 1 Introduction to Condition Monitoring of Electrical Machines

- Chapter 2 Background on Condition Monitoring Techniques

- Chapter 3 Noninvasive Methods for Motor Fault Diagnosis

- Chapter 4 Design and Development of a Noninvasive Condition Monitoring System

- Chapter 5 Faults Analysis and Evaluations via IPA and PVA Methods

- Chapter 6 Summary on Noninvasive Electrical Signature Analysis Methods: IPA and PVA

- References

- Index