- 400 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Mitchell's Structure & Fabric Part 2

About this book

Structure and Fabric Part 2 consolidates and develops the construction principles introduced in Part 1. With generous use of illustrations this book provides a thorough treatment of the techniques used in the construction of various types of building.

This new edition has been thoroughly reviewed and updated with reference to recent changes in building regulations, national and European standards and related research papers. The comprehensive presentation provides guidance on established and current practice, including the administrative procedures necessary for the construction of buildings.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Contract planning and site organisation

This chapter is concerned with the process which is essential prior to the actual commencement of building operations on the site, dealing with the planning of the contract as a whole and the organisation and layout of the site. The preparation and use of programmes for the various stages of the building work, by means of which the work may be controlled, is discussed together with an outline of the factors which must be considered at this stage. The means by which a programme of work may be expressed for use on the site are also explained.

The planning and control of all resources necessary to the realisation of building production is of vital importance and at some point before commencing work on the site, thought must be given to the way in which the building operation will be organised. Most builders plan their work in some form or another but, in the past, only a few have done so in much detail and have committed their plan to paper. Buildings, and consequently their construction, have become increasingly complex and the proper management of a contract and the control of cost, on the part of the architect at design stage and the contractor during erection, are more than ever essential if building is to be carried out efficiently both in terms of time and money. Only by proper planning can aids to productivity, such as mechanical plant, incentives, and efficient use of labour, become fully effective. With the greater mechanisation of building operations and the increased use of expensive plant, the contractor must obtain maximum use of the plant and speed the construction of the job in order to keep costs to a minimum. The design/erection continuum must be seen as a production process from inception to completion and there must be a programme on which the job may be organised, against which performance may be assessed and within which control may be exercised.

As pointed out in Part 1 the building and civil engineering industry is peculiar in that the contractor who will be responsible for carrying out the work usually plays no part in the design of a project, and has no opportunity at this point to contribute from his experience on matters of construction, planning and the nomination of subcon-tractors and thus to assist in the work being carried out efficiently, quickly and economically. Although a negotiated contract or engagement of a design and build partnership is often suggested as a means of overcoming this lack of collaboration at the design stage, it is not always suitable or acceptable since the element of competitive tendering is absent. In these circumstances as well as an appreciation of the concept of buildability1 it is essential that the architect should have sufficient knowledge of contract planning and of its implications to ensure a well organised job. Reference is made later to ways in which the architect can contribute to this end at the design stage.

Whether or not such contribution is made by the architect, the responsibility for actually carrying out the job in all its aspects is that of the contractor. In order to enable him to do this efficiently management methods common to other industries have become widely used in building.2 The contemporary view of construction management embraces a great number of interrelated activities drawing on a vast range of resources: professional, manufacturing, different categories of contracting and supplying, off-site production of components involving an increased use of transport, and specialised assembly methods.

The subjects of this chapter, contract planning and site organisation, together with general control, are the construction aspects of production management which itself is a part only of overall management in building. Planning makes efficient and economical use of labour, machines and materials, organising is the means of delegating tasks and control enables planning and organisation to be effective. It is possible here to deal with them only in outline and for a more detailed consideration reference should be made to other works.3

1.1 Contract planning and control

This involves working out a plan of campaign or a programme for the contract as a whole and assembling the necessary data. The primary function of such a programme is to promote the satisfactory organisation and flow of the various building operations during the course of erection, by planning in advance the times and sequences of all operations and the requirements in labour, materials and equipment. In order to fulfil this function and also to provide important information required during the contract, a well planned programme will have certain clear objectives. It should:

1 show the quickest and cheapest method of carrying out the work consistent with the available resources of the builder

2 ensure continuous productive work for all the operatives employed and reduce unproductive time to a minimum, by the proper phasing of operations with balanced labour gangs in all trades

3 provide an assessment of the level of productivity in all trades to permit the establishment of equitable targets for remuneration

4 determine attendance dates and periods for all subcontractors’ work

5 provide information on material quantities and essential delivery dates, the quantity and capacity of the plant required and the periods it will be on site

6 provide, at any time during the contract, a simple and rapid method of measuring progress, for the client and builder’s information and the issue of interim certificates for the valuation of work in progress for accounting purposes.

If a builder’s tender for any sizeable job is to be realistic, planning must start at the estimating stage and the following considerations must be taken into account: the most economical methods to be used for each operation and the sequence and timing of the operations, having regard to the resources at the contractor’s disposal; whether hand or mechanical methods will be most economical and the most suitable type of plant to be used in relation to the nature and size of the job; the space available and the best positions for the various machines to be used; the best methods of handling materials and the most suitable places on the site for the storage of materials and for the placing of huts; suitable points of access to the site for lorries and machines. In deciding what methods to use for construction and the most suitable plant for different operations, the estimator would, when necessary, consult the contract planning and plant departments of the firm or plant suppliers.

Traditional methods of production control have tended to be based on criteria of usefulness to site managers and indeed it must be kept well in mind that the site is where the building is finally assembled and where managerial control must be effective.

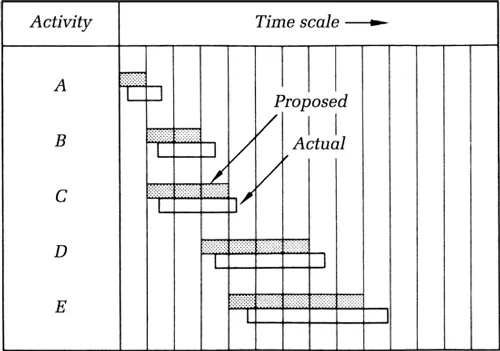

A typical site-oriented control device is the Gantt Chart or Bar Chart, which allows a fairly simple and easily read plan of operations to be made available to all site personnel against which may be plotted actual performances (see figure 1.1). However, this excellent device only takes into account one of the resources, time, and unless further schedules of the resources needed for each operation are also available adjacent to the Bar Chart it does not inform on the critical relationships between the various activities depicted nor does it enable procedures involving a number of variables to be optimised since the complex interrelationships affecting the outcome of any plan (or alteration of plan) are not readily evident or quantifiable. This can, however, be achieved by means of a technique known as Network Analysis.

Figure 1.1 Gantt chart

1.1.1 Network analysis

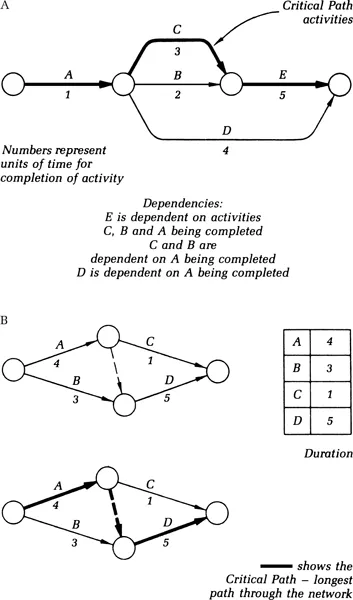

The essential difference between analysing a production problem by network as against linear or parallel linear methods lies in the identification of the dependency between operations. This approach leads to interrelated networks through which certain sequences can be seen to be ‘critical’ to the anticipated outcome in that they occupy the longest irreducible time required to execute the project (or part of the project) to which they are necessary. Figure 1.2 shows this in a simple set of five interrelated activities A, B, C, D, E of time values 1, 2, 3, 4 and 5 days.

Figure 1.2 Network or Critical Path diagrams

In preparing a network the project is broken down into its operational parts (this can be at a strategic level or in extreme tactical detail) termed ‘activities’ which are represented by linear arrows (figure 1.2 A). The arrows are arranged to show the sequence of activities necessary to the occurrence of ‘events’ (shown by circles) which must precede further sets of activities. Activities (with the exception of ‘dummy’ activities) take up time, including waiting time, whereas events do not. An event cannot be said to have occurred until all the activities leading to it have been effectively completed.

Dummy arrows are used to show dependencies where activities are not directly sequential. For example in figure 1.2 B activity C is dependent on A being completed. D is dependent on A and B being completed – shown by use of a dummy arrow. Dummy arrows have no time value but may still lie on the critical path if the activities they link are critical.

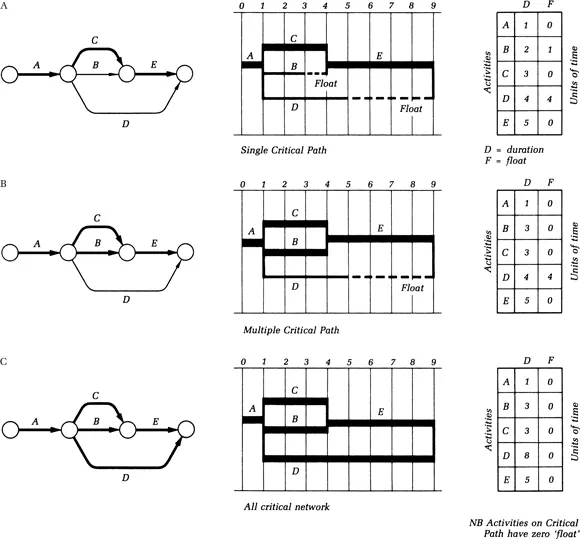

Figure 1.3 A, B, C shows how variations in time ascribed to the activities will result in different critical paths and how, in the case of C, all sequences can become critical. In theory the most perfect plan would result in an ‘all critical’ network but in life this would lead to a wholly inflexible situation lacking any time to manoeuvre or rethink situations. It is in this context that the ‘float’ or difference in time between the non-critical and the critical activity times becomes important to the production planner working in changing circumstances, in that he will be given options as to how he may deploy resources.

Figure 1.3 Network or Critical Path diagrams

It is often convenient for the network to be set up initially using non-scaled linear arrows to represent the sequence interrelationship of activities and then to plot the network against a linear time scale as a prelude to examining the distribution of resources and to the preparation of a bar chart form of presentation. The generalised network statements shown in figure 1.3 A, B and C are each shown developed in this way in time scale form.

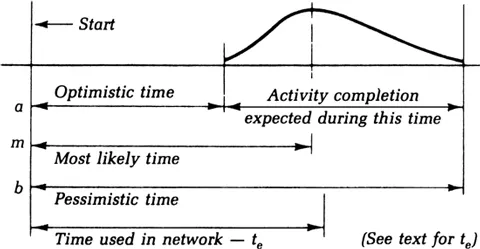

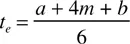

Although time is the planner’s main parameter, other factors will affect the final assessment of times to be ascribed to the constituent activities of a network, e.g. cost, labour and material availability and the demands of other projects under the planner’s control. It is convenient to think in terms of a ‘normal’ time when planning initially and figure 1.4 shows a statistical method of arriving at the time envisaged for an activity, given some historical data, using a Beta distribution in which the area under the curve represents the probability of the time expended on an activity lying between any given points along the baseline time scale. This particular distribution curve yields the formula:

Figure 1.4 Activity times

where te | = estimate of time to be used in network |

a | = optimistic or shortest estimate of duration time |

b | = pessimistic or longest estimate of duration time |

m | = most likely duration of activity judged from all available evidence. |

However, there are occasions when the control of a project requires more sophisticated analyses to be carried out to allow the planner to respond to varying criteria for productivity: such as time/cost optimisation, levelling of resources and/or deployment of resources amongst a number of projects.

Time/cost optimisation This technique explores the possibilities of altering produc...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Acknowledgements

- Preface to seventh edition

- Foreword

- 1. Contract planning and site organisation

- 2. Foundations

- 3. Walls and piers

- 4. Multi-storey structures

- 5. Floor structures

- 6. Chimney shafts, flues and ducts

- 7. Stairs, ramps and ladders

- 8. Roof structures

- 9. Fire safety

- 10. Temporary works

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Mitchell's Structure & Fabric Part 2 by J S Foster in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Construction & Architectural Engineering. We have over one million books available in our catalogue for you to explore.