![]()

1

Measuring energy consumption

Energy savings cannot be made on a sustainable basis without an appreciation of where energy is being used, for what reason, and what may be influencing consumption patterns. Energy use and energy savings must also always be quantified and recorded in order to check that they are accurate. This chapter moves from a basic discussion of how energy is used, through conducting an energy audit, to techniques for regular energy measurement and monitoring. All of this is a prelude to identifying excessive energy use, consequent potential energy conservation measures, and a full measurement and verification (M&V) plan.

Energy units

Energy is described using several different units, but they must be harmonised for comparison purposes. The SI unit of energy is the joule. Other units of energy include the kilowatt-hour (kWh) and the British thermal unit (Btu). One Btu is equivalent to about 1055 joules, and one kWh is equivalent to exactly 3.6 million joules. Full conversion tables are given in the Appendix, together with tables converting fossil fuel energy use into greenhouse gas emissions and other vital information. These are necessary to convert energy use in different contexts to the same units for calculations.

Energy sources

Energy arrives in a building from many directions: from direct sunshine, from an electricity supply, from fuels such as gas and oil which are burned for heating, and from heat arising from activities, including the heat of human bodies. Energy is used in many ways in buildings: for space heating and cooling, for water heating and cooking, and for lighting and equipment such as motors, fans, PCs and freezers/fridges.

Energy efficiency

Energy never disappears: once used, it just becomes converted into another form, usually heat. In this case it is absorbed into the fabric of the building, through it and into the environment outside. It is a general rule that in any system, energy in equals energy out. But some of this energy may be stored within the building fabric, or even in specific energy storage such as hydrogen, hot water tanks or batteries. The control of heat energy in and out is governed by the building structure and fabric itself, how this is managed by the people within it, and the heating, ventilation and air conditioning (HVAC) system. These issues are covered in Chapters 3 and 6.

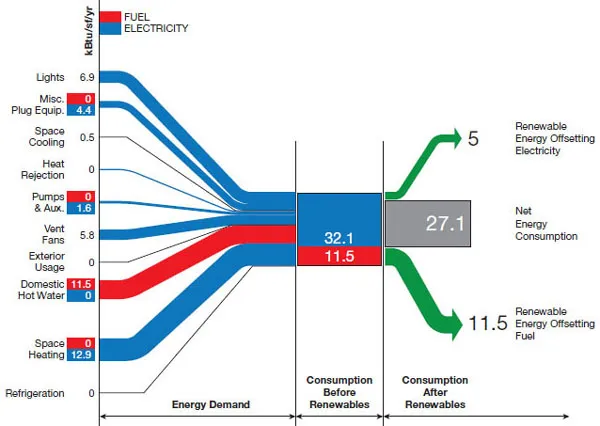

Figure 1.1 This diagram shows the amount and applications of energy in a block of flats, and how it is satisfied. Red is heat (fuel) and blue is electricity. In this particular case, some heat is supplied by solar water panels and some electricity by solar electric modules, indicated on the right.

Source: Premnath Sundharam

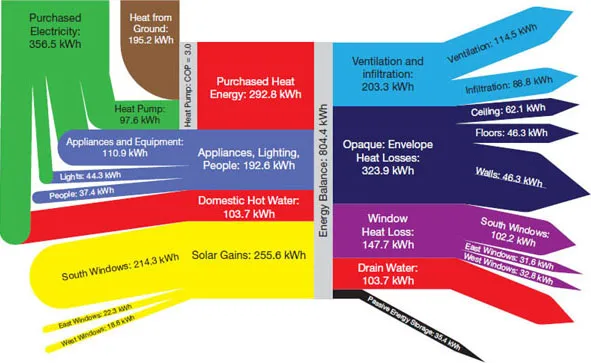

Figure 1.2 Diagam showing the energy balance of a hypothetical building. Sources of energy entering are on the left, and ways in which it leaves are on the right. The total energy balance is quantified in the centre.

Source: ‘Preliminary Investigation of the Use of Sankey Diagrams to Enhance Building Performance Simulation-Supported Design’, William (Liam) O’Brien of Carleton University, Ottawa

Efficiency is measured by the amount of useful work conducted by the energy supplied. This is where energy is converted into power. The energy which is wasted in this process appears as heat. Some heat may be reclaimed and reused, as we shall see in Chapter 6, but there is a natural limit to this process. Sometimes this heat is unwanted, but it must still be efficiently dealt with; an extreme case of this is in data centres or server rooms, which are discussed in our companion book, Energy Management in Industry.

Specifically, the following are the definitions of efficiency for different types of energy use:

- Electrical: useful power output per electrical power consumed;

- Mechanical: the proportion of one form of mechanical energy (e.g. potential energy of water) that is converted to mechanical energy (work);

- Thermal or fuel: the useful heat and/or work output per unit of fuel or energy consumed;

- Lighting: the proportion of the emitted electromagnetic radiation usable for human vision;

- Total efficiency: the useful electric power and heat output per fuel energy consumed.

It often makes sense to talk about the efficiency of an entire system or process, such as how much electricity is consumed to produce 1000 widgets. It is extremely important to be clear on the units that are being used and the type of efficiency being measured, otherwise confusion can result.

For example, there is a difference between Europe and America in the definition of heating value. In the US and elsewhere, the usable energy content of fuel is typically calculated using the higher heating value (HHV), which includes the latent heat for condensing the water vapour emitted by burning the fuel. In Europe, it is the convention to use the lower heating value (LHV) of that fuel, which assumes that the water vapour remains gaseous, and is not condensed to liquid water so releasing its latent heat. Using the LHV, a condensing boiler, which makes use of this latent heat, can achieve a “heating efficiency” in excess of 100 per cent, whereas, of course, using HHV, this efficiency is around 90 per cent, compared to 70 to 80 per cent for non-condensing boilers.

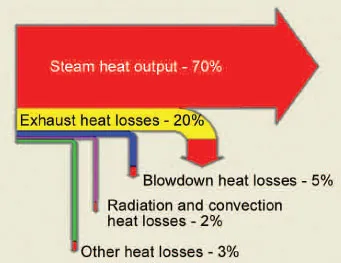

Figure 1.3 Diagram showing the heat losses from a non-condensing boiler. All processes lose energy as heat.

Source: Author

The aim of energy management is to improve the overall efficiency of the entire systems for which the manager is responsible: to get more work out for the energy in, and certainly to make use of the free energy that is available, principally from the sun. It is important to note that this free energy, most of which is called ‘passive gains’, is not directly measured, yet it is a powerful factor within the controlled environment. In calculations to determine building efficiency strategies, it needs to be taken into account. This is covered in Chapters 3 and 5.

Energy audits

A European and world standard for energy audits, published in October 2012, BS EN 16247–1, explains the process of conducting an energy audit in great detail, defining the attributes of a good-quality energy audit, from clarifying the best approach in terms of scope, aims and thoroughness to ensuring clarity and transparency. It specifies the requirements, common methodology and deliverables for energy audits. It applies to all forms of establishments and organisations, all forms of energy and uses of energy, excluding individual private dwellings, and is appropriate to all organisations regardless of size or industry sector.

It was developed by members of ESTA (the Energy Services and Technology Association), the Energy Institute, Institute of Chemical Engineers, and Energy Services and Technology Association in Britain, in response to the 2006 EU Directive and in anticipation of the Energy Efficiency Directive, that mandates member countries to create regular energy audits for large organisations. It complements the energy management system standard, ISO 50001:2011 which identifies the need for clear energy auditing. At the time of writing, further, more specific standards are being developed but will be available soon: energy audits for Buildings (EN 16247–2), Processes (EN 16247–3) and Transport (EN 16247–4).

The first step is to discover where all the energy comes from and where it goes. When this is done it can be compared to an established benchmark of energy use for the building, company, organisation or facility.

Establishing the baseline

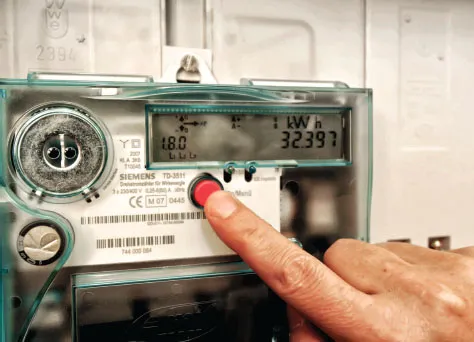

Energy used is either metered or unmetered. Metered information may be gathered from invoices from suppliers and utility companies and from the meters directly. It is necessary to make a list of all meters and sub-meters. This will detail their location, what fuel or energy source they measure, the zone or equipment they serve, the units of measurement, the reading recorded at present (with the time and date), and some other identification such as a serial number. Often, they are photographed. A policy should be set to determine how frequently these are read and by whom. These people need to be taught how to do it, so that everyone is reading the meter in the same way.

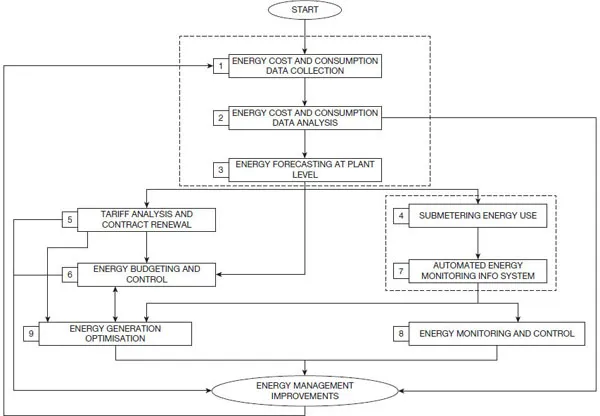

Figure 1.4 The process of auditing, benchmarking and performance optimising.

Source: Carbon Trust

Figure 1.5 Modern smart meters provide half-hourly measurements, and even enable the utility companies to provide their customer...