1.1 Energy in context

Energy is at the heart of nearly every process in the modern world. The story of the development of energy has mirrored the evolution of human society, and underpinned the rise and fall of civilisations. Water power has a long history within this story, and has changed and reinvented itself as technology, materials and needs have developed. The narrative of wealth, of growth and of increasing debt is facilitated by the confident expectation that cheap energy, in a form which is concentrated, storable, stable and reliable, will continue to be available in increasing volumes into the future. But what if the current model of energy is straining at the seams? What if the energy we use is not as reliable and ‘cheap’ as we are used to, and where does this leave water power – probably the oldest form of energy which man has learned to call upon.

Human societies have always relied on food for basic energy, both directly and indirectly to feed the beasts of burden which provided muscle for the agricultural revolution. This revolution sowed the seed of settlement which allowed our ingenuity to invest time and effort in harnessing the resources around us in order to ease the grind of daily life.

The history of water power can be traced back millennia, where waterwheels crop up in many civilisations; it is widely accepted they were invented in ancient Greece, spreading to Rome, India and the Islamic world. In ancient China the technology was separately developed using a distinctive horizontal layout. It is sure that these older civilisations harnessed water power extensively, so it is interesting to speculate why the industrial revolution eventually sprang up in the British Isles in the eighteenth century.

Whilst the development of processes which wheels powered was wide, the epochal use was for the milling of grain into flour. This developed early and continues to the present day.

Because the flow of water is relatively reliable, and the necessary preconditions of an energetic stream widespread in areas where humans have settled, use of the waterwheel has been made in a very wide range of processes – almost any industry which was established before and during the early industrial revolution: mining for pumping and processing, metal production for stamping and driving bellows, paper making, textiles (wool and cotton notably), milling of many grains or more abstract applications such as gunpowder mills, slate mills or snuff mills.

The cradle of the industrial revolution typically involved areas where water power was abundant; in the UK from Coalbrookedale to the Derwent valley water was vital to power the processes to produce the products which Britain traded. As demand increased and the power required increased, the waterbodies of Britain were harnessed to an extraordinary extent, the evidence of which is still around today.

Eventually improvements in technology allowed the development of steam engines, from the early inefficient atmospheric engines of Newcomen, to the more efficient machines of Boulton and Watt, where the laws of thermodynamics were better mastered, and from where the march of fossil fuels first gained a decisive advantage from natural power sources, exemplified by water power. With the scalability of steam engines, the ability to operate at any time, and the ability to locate wherever was most economical, the foundations for our current energy model were cast. Whilst water power, where available, was always economical, it required backup (an interesting parallel with renewable energy today) if the process to be operated was to be carried out at any time, and as the scale of industry grew, it could not usually be the primary energy source. Britain led the world in extraction of coal, mining hundreds of millions of tons of coal every year by the early twentieth century. Upon this cities were built, communities sustained and industry thrived.

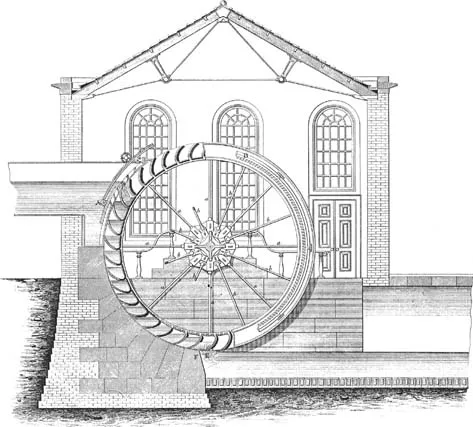

Figure 1.1

Fairbairn waterwheel.

Picture courtesy Martin Watts

Figure 1.2

Many industrial processes were powered by water, such as this machinery at an ‘edge mill’ producing agricultural implements.

Photo courtesy Adrian Coulston, NT

As electricity became used for lighting, water power was at the forefront. Initially local grids sprung up, often supplying an individual property, community or town. Many such systems were a microcosm of the national grid – balancing supply demand with water power, peak lopping oil powered generators, and even pumped storage schemes which were installed from the late nineteenth century. But in another parallel with earlier developments, as the government sought to make the benefits of electricity available across the whole country, water power plants fell into disrepair to be replaced by larger coal fired power stations and striding pylons. Across Europe, large hydro plants were installed, and in places such as Scotland were used as a tool of social improvement, bringing opportunity to the sparsely populated Glens whilst providing significant power for the UK grid.

Figure 1.3

A dam feeding into a large-scale hydro plant.

Author’s own photograph

Society’s movement from steam powered railways to oil powered cars over the twentieth century ensured that oil has become central to the highly mobile way we live our lives now, and ensured that oil is not used widely in electricity generation any more, as it is too valuable as a transport fuel.

As UK coal supplies dwindled, new nuclear technology appeared to offer a brave new postwar world of energy too cheap to meter. Whilst the early promises of nuclear energy were never achieved, and the psychological scars of the Cold War and accidents at poorly designed and hastily built nuclear plants took their toll, the technology developed a niche. Britain was saved from the long-term effects of miners strikes in the early 1970s by the North Sea, a bounty of oil and gas which we have spectacularly (half) burnt in a little over a generation. The oil brought revenue and fed our vehicles, the gas fed a first ‘dash for gas’ in the electricity sector which has thus far been the backbone of the UK’s carbon emission reductions which we have realised we must achieve.

Now we are looking at very significant further investments to liberate gas from ‘tight’ formations on and offshore, which require physically fracturing the rock formations to release the gas, a process which may only be viable with energy costing over $150/barrel oil equivalent.

Figure 1.4

Energy too cheap to meter? Dounreay experimental fast-breeded reactor.

Photo courtesy Nuclear Decommissioning Authority

Figure 1.5

The money we pay to fill up the tank supports the large infrastructure often in far flung parts of the globe which enables crude oil extraction.

Photo courtesy Nuclear Decommissioning Authority

As ever in a changing world we find ourselves looking at a very difficult question – where do we go from here? How do we decarbonise, achieve energy security and constant 3 per cent growth in a finite world?

GDP and per capita energy use are closely linked – no government has ever broken the link – at best bending the link a little. The UK government has sometimes claimed that it has broken the link between carbon emissions and growth, but this is an illusion, achieved by the move from coal to gas generation, and the offshoring of much of the manufacture of goods and energy intensive industry to countries like China. So whilst our current UK based emissions have reduced from 1990 levels, we rely on products manufactured in China, and we therefore are responsible for some of the Chinese and other manufacturing country emissions. Accounting for this, the link between energy use and GDP is unbroken.

And now we can afford less energy.

Global oil prices are averaging over $100 per barrel over sustained periods, production is stagnating globally, and falling in many leading producers. Fuel prices are at record levels, and for the first time in many years, use is declining in many Organisation for Economic Co-operation and Devel...