- 646 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

An Introduction to Operations Management: The Joy of Operations covers the core topics of operations management, including product and service design, processes, capacity planning, forecasting, inventory, quality, supply chain management, and project management. Das provides a clear, connected, and current view of operations management and how it relates to a firm's strategic goals.

Students will benefit from the real-world scenarios that foster an understanding of operations management tasks. Without relying heavily on statistics and mathematical derivations, the book offers applied models and a simple, predictable chapter format to make it easy to navigate.

Students of introductory operations management courses will love this practical textbook. A companion website features an instructor's manual with test questions, as well as additional exercises and examples for in-class use.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

1

Operations Management and You

- A practical understanding of the purpose and tasks of operations management

- Jobs—the benefit of studying operations management

- How to evaluate operational performance

- What’s happening now in operations management

Operations Management and You: A Road Map

Introduction

1.1 What, Exactly, Is Operations Management?

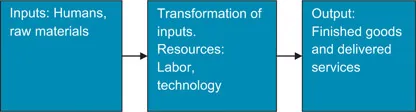

1.1.1 A Way to Think about Operations

1.1.2 What Operations Managers Do

- Exclusivity—every dress shown is different

- Affordability—a reasonable price

- Quality—good fittings and durable colors

- Availability—the dress will be there when you want it

- Service—friendly expert advice and help

- Location—right off the subway and plenty of safe parking

Every Business Makes Promises

- Toyota promises efficiency, safety, longevity, innovation: http://www.toyota.com/productleadership/

- Kia promises the “power to surprise” with “exciting and enabling” vehicles: http://www.kia.com/#/about/

- Ritz-Carlton promises to be and always be the “gold standard” in luxury hospitality: http://corporate.ritzcarlton.com/

- Motel 8 promises consistent delivery of eight features in a guest stay: http://www.super8.com/Super8/control/amenities?variant

- a) First, by building forecasting systems that attempt to anticipate variability—this, obviously, can never be perfect.

- b) Next, they try to control variability by influencing demand patterns (e.g., doctor appointments, happy hours), controlling worker variability (e.g., worker training and incentives), and managing supplier variability (e.g., information sharing, technical assistance, incentives, and penalties).

- c) Since forecasting and attempts to control variability typically offer limited results, managers build in excess capacity in the system (labor, machines, raw materials) so that peak demand can be met. This leads to waste at times of low demand and costs the business a lot.

- d) Alternatively, managers try to make their operations synch with variability by adding flexibility to work systems. Basically, they convert fixed costs into variable costs. Think of hiring temps, varying worker hours according to demand, training workers to perform different jobs, leasing equipment/hour instead of buying, and buying materials when needed instead of holding inventory. Such actions are not always possible.

Operations Manager Responsibilities

Dutie...

Table of contents

- Cover Page

- Half Title Page

- Title Page

- Copyright Page

- Dedication

- Contents

- List of Figures

- List of Tables

- List of Take-Away Boxes

- Preface

- Acknowledgements

- Introduction

- 1 Operations Management and You

- Part I Designing Products and Processes

- 2 Product Design

- 3 Process and Service Design

- Part II Managing Processes

- 4 Managing Processes

- Part III Improving Process Performance

- 5 Business Forecasting

- 6 Capacity Planning

- 7 Managing Capacity

- 8 Managing Inventory

- 9 Managing Quality

- 10 Supply Chain Design

- 11 Managing Supply Chains

- Part IV Finding the Right Location

- 12 Location Decisions

- Part V Working with Projects

- 13 Managing Projects

- Statistical Tables

- Index