![]()

Part I

Materials and performance

![]()

Chapter 1

Understanding the material

1.1 Types of timber

Timber is obtained from the trunks of commercially available trees, with the branches and root wood being increasingly used for their fibre products or reduced to wood pellets for fuel (or composted and returned to the land to boost fertility). Some trunks will come from sustainably managed forests while others, probably the majority of the larger diameter, straight section trunks, from the cropping of virgin forests. This is not necessarily an ultimately debilitating activity because forestry brings wealth to that region. But the specifiers of the timbers’ end use need to be sure that the activity was undertaken within the internationally accepted environmental and other codes of practice, such as those of the Forest Stewardship Council (FSC), Pan European Forest Certification (PEFC), Sustainable Forest Industry (US SFI), United Kingdom Wood Assurance Scheme (UKWAS), the Canadian National Programme, the Malaysian Timber Council and other similar programmes which help to ensure sustainably managed reforestation.

Chapter 2 deals with the issue of ‘Certification of a Sustainable Product’ in more depth. Clearly the procurement of timber from a sustainable source also must be accompanied by a Chain of Custody Labelling, so that the wood supply chain can be tracked from source to end use and beyond. In this, the establishment of consumer awareness and confidence is critical.

Two types of commercial timber are available from temperate or tropical forests, universally referred to as softwood or hardwood. These yield a very wide range of products, whose quality and performance depend on a clear knowledge of appropriate sawing techniques and subsequent engineering processes. The link between the natural structure and characteristics of wood and their resulting physical and mechanical properties is very well described in the really excellent book by F. J. Keenan, of the Faculty of Forestry, University of Toronto, entitled Limit States Design of Wood Structures.1

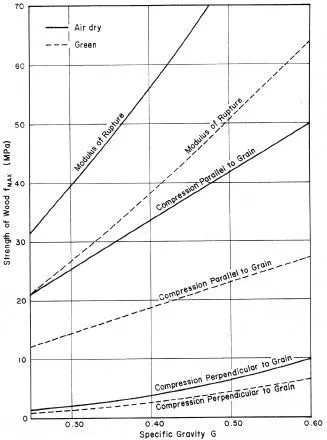

As a general principle, the modulus of rupture and compressive strength parallel and perpendicular to the grain of different timber species are related to their specific gravity, with the denser softwoods and hardwoods being stronger than those with less dense grain. No species illustrates this principle better than balsa, whose ultra-low density results in lower strengths than almost all softwoods, despite balsa technically being a tropical hardwood. Naturally, dry timber is stiffer and stronger but less subtle than green timber.

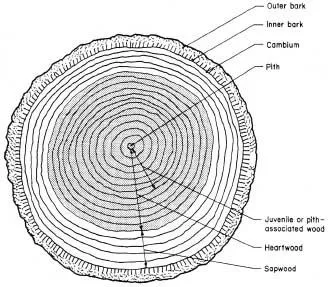

Figure 1.1a Cross-sectional view of a log1

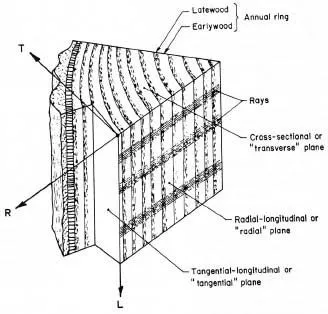

Figure 1.1b Principal directions and planes of wood

Credit: Morrison Hershfield Ltd.

Figure 1.2 Measuring the diameter of larch in the stock pile for Savill visitor centre

Credit: The Crown Estates. Photo Warwick Sweeney.

Figure 1.3 General strength properties related to density1 Credit: Morrison Hershfield Ltd.

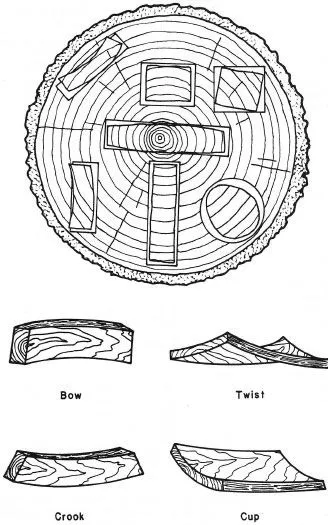

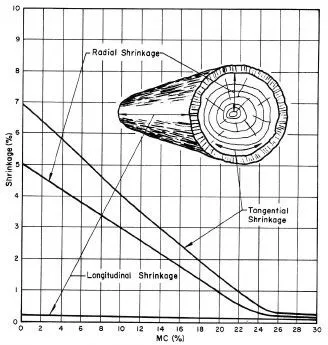

The degree of shrinkage in a sawn timber and the warping during its life are both affected by the characteristics of the wood itself, the orientation of grain and by the method of sawing, and by the shrinkage stresses set up during the drying process. These stresses that cause warping are built up during the reduction of moisture content from something below 20 per cent down to 12 per cent or so.

Softwood comes from conifers, which have needle-shaped leaves that remain on the trees for years, so that most (but not all) conifers are evergreen and cone bearing. Most softwood used for construction comes from the sustainably managed temperate conifer forests of Scandinavia, North America, New Zealand, Japan and the United Kingdom. Commonly used softwood species are Sitka spruce, European whitewood (silver fir, Norway spruce), Douglas fir, redwood/Scottish pine, and European larch. For construction, timber must have a moisture content of less than 17 per cent (ideally, for dimensional stability within a built environment, 12–15 per cent) and be detailed in its location as part of the building to maintain this level during its lifetime.

Figure 1.4 Change of shape of a cross-section of sawn timber1

Credit: Morrison Hershfield Ltd.

Figure 1.5 Shrinkage of wood in its three principal directions1

Credit: Morrison Hershfield Ltd.

In Europe, softwoods such as pine and spruce grow to a maturity of 25 m or so with a base diameter of 300–600 mm, restricting section sizes to a 270 mm ‘square’ section or so (i.e. up to 275 × 75 mm joists) or multiples thereof. In North America forests, mature old trees up to 75 m with diameters at the base of up to 1 m are still available to harvest. Such sections easily yield 300 × 300 mm baulks that are straight, clear, knot-free and reasonably straight grained. Increasingly, smaller stands of mature trees are being harvested in Europe from woods that include Douglas fir, Western hemlock, spruce, pine and fir. Western red cedar with its superior durability and lightness is also available for exterior cladding sheeting, summerhouses, and similar light structural uses.

Selection of timber to achieve a particular level of durability and robustness, perhaps in conjunction with preservative treatment to protect against fungal or insect attack must then be carefully made, as outlined in Chapter 3, ‘Improving the Material’.

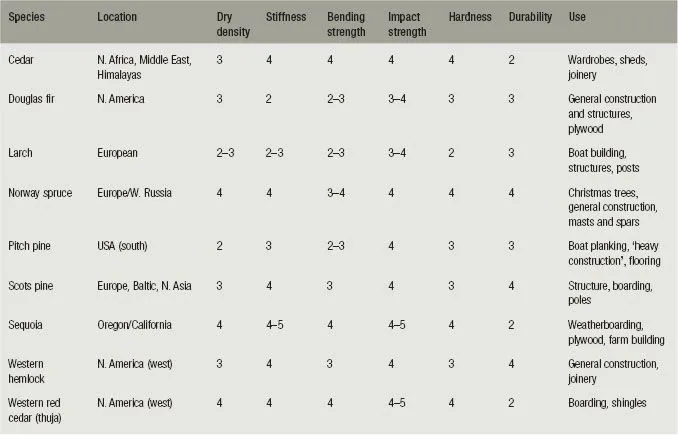

Table 1.1 Relative characteristics of softwoods (1 = high, 5 = low)

Additionally, architectural or regulatory requirements may require the application of treatments to improve flame spread resistance or fire resistance itself. Although it has to be said that the effects of charring in a fire, particularly of larger cross sections, will often ensure that the timber element of reduced effective cross section will outlast many other structural materials in severe fires.

Hardwood timbers derive from broad-leaved trees that are generally (but not always) deciduous. They occur in both northern temperate forests and in tropical rain forests. Northern temperate forests in Europe and North America can be a source of sustainably managed oak, beech, ash, and elm, while tropical hardwoods are sourced from three main regions of the world. Malaysia and Indonesia provide a source of functional timbers such as merantic, lauan, keruing and ramin while Burma and Java export teak. Traditionally, mahogany has been exported from West Africa and more recently from Latin America. Eucalyptus from Africa and South America (and elsewhere) is also increasingly being grown for architectural and engineering use. Care is needed in selection of these hardwood species to ensure they arise from a sustainably stewarded source. In all cases it is essential that supplies be specified by the architect/engineer/builder from an accredited ‘chain of custody’ that leads back to a sustainably managed forest environment, as discussed further in Chapter 2.

1.2 Understanding the performance of wood

To use wood with intelligence, we must first understand the wood.2

The architect Frank Lloyd Wright is telling us that the behaviour of wood products in construction depends on the anatomical and chemical organisation of the original wood as well as the characteristics acquired by it in the conversion process.

Only a very few trees (typically 145 out of over 1,000 seedlings per hectare) will reach full maturity – some die, many are crowded out as the forest matures and in some cases skilful harvesting will thin the trees on a controlled basis. This can allow the winning of a perpetual crop of logs from the woods without blanket replanting. By this later means erosion of soil is inhibited, rapid water run off reduced and the woods can retain their biological diversity and amenity value.

Each year the tree grows steadily taller and stouter at the base as the roots draw water and mineral salts from the soil and the leaves in the canopy extract carbon from the air through the process of photosynthesis. In temperate forests, each spring and summer a new woody layer is formed between the existing wood and the inner bark: this new wood envelops the entire stem, living branches and roots, and is visible as a ‘growth ring’, particularly on the end of cut logs (see Figure 1.1a).

In years of full sunlight and adequate water, these rings are wide, but on the other hand, slower growth in more northern regions leads to tighter ring patters which in turn can be converted to stronger, stiffer timber (provided the tree is free of imperfections such as distorted, twisted or severely inclined grain, knots or from the past effect of extreme loading). Tropical conditions with little seasonal variation yield timber with indistinct or absent rings.

The nature of this wood growth is of some importance to the eventual characteristic of the timber. Wood is composed of cells with walls varying in thickness in different species and mostly aligned axially along the trunk with the ‘grain’ of wood. The juvenile wood formed in early years is thus nearest the centre (or pith) with the latest wood nearest the outside. This is adjacent to the sapwood zone, which is still active in carrying up water and minerals to the canopy and as a ‘food’ store. The inner zone is the ‘heartwood’ and is usually darker than the sapwood and is inactive. Heartwood is formed when food materials in the sapwood are transformed, giving rise to the colour difference between the lighter sapwood and the heartwood.

1.3 The durability and preservation of timber

In addition to change in appearance, the chemical and structural changes in heartwood can give the heartwood timber increased durability against fungi and insects as compared to the sapwood. Unfortunately, most commercial softwood timbers are processed from trees of relatively small diameter that do not have substantial heartwood centres and so may require additional preservative treatment even for internal usage. Timber species have been classified into five classes of natural durability as shown in the table below.3

Various means of treatment are available to improve their natural durability. The effectiveness with any treatment process depends on ease of penetration of preservative into the interior cell structures. This in turn, and the preservation measures selected, depend on the permeability of the heartwood, so timber is classified from the point of view of preservative treatments as permeable, moderately resistant, resistant or extremely resistant. Sapwood that is not inherently durable is generally permeable and so can be effectively treated to become durable, so long as the preservative measure is legally acceptable from a long term environmental perspective.4

Table 1.2 Durability classifications3

Class | Example | Life in ground |

Very durable | Example | Life in ground |

Durable | Teak, greenheart | +25 years |

Durable | White oak | 15–25 years |

Moderately durable | Sapele, Douglas fir | 10–15 years |

Not durable | Elm, pine, | 5–10 years |

Perishable | Beech, birch | 0–5 years |

Credit: B. T. Batsford Ltd.

This is elaborated further in Chapter 3, ‘Improving the Material’, where the advantages of the carefully controlled use of effective preservatives leading to longer useful life have to be weighed against the potential impact on the environment over that life in respect of:

• Preventing fungal and insect attack

• Improving spread of flame resistance and behaviour in fire

• Finishes and paints to give weather resistance and provide decoration, including

• the potential use of nano coatings.

In general, the need for preservation can be categorised according to location. It is unnecessary for well detailed interior joinery, ‘optional’ for pitched roof timbers, ground floor joists, ‘desirable’ for external wall members and flat roof timbers and ‘essential’ for external timbers in contact with the ground, sole plates, etc.

Designers and specifiers need to give very careful consideration to which treatment grade is best and in particular detail the construction so that moisture cannot accum...