![]()

HOW TO ESTABLISH “SUCCESS IS ASSURED”

PRIOR TO MAKING

DECISIONS IN YOUR ORGANIZATION I

Part I begins with a case study of Pratt & Whitney and then explains the lessons learned from our work with dozens of similar organizations, refined into clear how-to instructions for an organization’s decision-makers at all levels.

![]()

Chapter 1

Pratt & Whitney Case Study: Their Journey to “Success is Assured”

The rest of this book will give specific how-to advice that you can implement in your organizations. To set that up and sensitize you to the challenges you will likely face in initiating such changes, this chapter will give concrete examples of trying to make such improvements within a complex organization. It will allow you to see both what worked well and what did not work so well. It will also illustrate the importance of many of the elements that will be described in the following chapters (as many of them were inspired by experiences such as these).

Further, in most of the organizations where the content of this book has been taught, there are at least a few people that have trouble focusing on the recommendations because they see so many obstacles to their adoption in their organizations. Often, the less vocal people will also share that they too were highly skeptical this would actually have an impact due to those obstacles. One of the most common questions is

Where has this been done successfully in a company like ours?

It seems the vast majority of people don’t want to be first adopters. And they don’t want to waste their time learning new skills if their organization’s management or situations will end up preventing those skills from being used.

So, to allow readers to focus on the teaching in the rest of this book, this chapter will try to address this question up front. Obviously, it can’t answer this for your specific company, but it can walk through a case study of a company that has many, if not most, of the challenges and obstacles that you are concerned with in your own organization. And even with such obstacles leading to only partial adoption (so far), the effort has had significant value and they continue to be interested in progressing further.

This case study will attempt to make clear that the techniques taught in this book are applicable in the real world, that they can be applied despite the obstacles, and that the skills you learn will make you and your organization more effective, even if there is only partial adoption.

The Setting: Pratt & Whitney

Pratt & Whitney (P&W) is a world leader in the design, manufacture, and service of aircraft engines and auxiliary power units, and has been powering aircraft for over 90 years. Founded in Connecticut in 1925, P&W’s first aircraft engine — the air-cooled Wasp (Figure 1.1) — transformed the aviation industry with its unprecedented performance and reliability.

Figure 1.1 First P&W Wasp engine built.

P&W has been leading change ever since. Today, P&W develops game-changing technologies such as the PurePower® PW1000G engine with patented Geared Turbofan™ engine technology. Its large commercial engines power more than 25% of the world’s mainline passenger fleet, and its military engines power front-line fighters and transport aircraft for 311 armed forces around the world.

So, P&W is a very large company, with more than 38,000 employees worldwide and $15 billion in adjusted net sales (2016). In that sense, P&W serves as a good example given that adopting change can be much more challenging in large, well-established companies.

Even more challenging, P&W is just one of four business units of the larger United Technologies Corporation (UTC; NYSE: UTX), which serves customers in the commercial aerospace, defense, and building industries and ranks among the world’s most respected and innovative companies. UTC employs more than 200,000 people in more than 70 countries worldwide and has adjusted net sales of $57 billion (2016). It is ranked 45 in the Fortune 500. The other three business units are Otis, UTC Climate Controls & Security (key brands: Carrier, Chubb, Kidde), and UTC Aerospace Systems (key brands: Hamilton Sundstrand & Goodrich Aerospace).

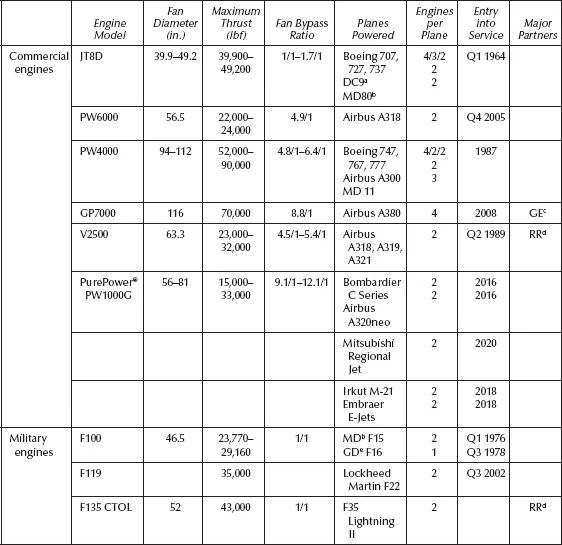

P&W develops and manufactures a fairly large number of very complex products (jet engines and auxiliary power units) that have extremely high reliability requirements and yet often need to push the boundaries on performance. Table 1.1 shows a sample of those products and the aircraft they power.

Table 1.1 Sampling of P&W Engine Models

Source: pw.utc.com

aDouglas

bMcDonnell Douglas

cGeneral Electric

dRolls Royce

eGeneral Dynamics

If you are on an airplane and can see the engines outside your window, look for the P&W eagle (Figure 1.2) and you will know you are flying on the most dependable engines in the world!

Figure 1.2 Engine with P&W eagle.

Establishing “Success is Assured”: The Promise and Challenge

In order to establish that “Success is Assured” prior to making key decisions, an organization must be willing to spend more time learning fuzzy knowledge in the earliest phases of product development, delaying decision-making until that learning can be completed. Doing so can seem counter to traditional approaches that focus on leveraging sophisticated back-end simulation and/or testing capabilities to do the learning, and thus try to quickly nail down the requirements and then the specifications in the front end to more quickly get to those back-end analyses. The sooner we can get to those analyses, the sooner we can learn what is wrong (the “bugs”) and focus on fixing them. However, those “bugs” can consistently be traced to key decisions that were made early in the process.

The promise of establishing “Success is Assured” prior to making those decisions is avoiding the time and money wasted in all the rework (redesigning, reanalyzing, and retesting), which can consume 60%–80% of your engineering capacity. But the costs don’t end there, as production hardware is already on order and qualification testing is on a tight schedule to meet the customer deadline. To recover, hardware on order must be canceled and qualification testing delayed and rescheduled, frequently leading to expensive cancellation fees and unhappy customers. Replacement hardware is needed quickly, incurring costly expediting fees. Costs and delays just keep adding up.

Given that, establishing “Success is Assured” at P&W may seem like common sense, but its complexity is immense. Between the size of the company, government regulations, and customer requirements that often challenge the boundaries of physics, the task of facilitating change is daunting. And then there are additional complexities:

■ Materials are highly specialized to withstand the extreme environments required.

■ Capable suppliers are limited and manufacturing lead times are long.

■ Orders must be placed as soon as possible to meet aggressive development and production schedules. (This means that orders are placed before the preliminary design is complete.)

■ Engine systems’ interrelationships and their effects are hard to predict.

■ Data for current and past engine configurations may not help when new technologies are introduced to meet customer requirements. Unknowns are elusive until the engine is tested.

Convincing P&W management they could establish that “Success is Assured” despite the cost and schedule pressures wasn’t going to be easy. Can a company with products as complex as jet engines really learn early enough, efficiently enough, and complete enough to avoid huge redesign and analysis efforts to flesh out all the issues?

My name is Penny Cloft, Senior Fellow Discipline Lead (SFDL) emeritus. I had a partner in this journey: Brian Gracias, Engineering Quality Manager and Six Sigma Master Black Belt. Brian and I share a passion for process improvement and together led the charge to change Pratt & Whitney’s product development process with the help and support of many fellow P&W employees along the way.

This case study will give you a response to those who push back because they believe your products are too complex, your obstacles are too diverse, or your organization is too entrenched in existing practices.

Read this story with an eye to adapting the principles and implementation to suit your company’s situation. Keep your focus on what was done, why it was done, and how it will relate to your company. Keep in mind there are two interwoven tracks on this journey: the P&W (company) story of change and the personal learning of change agents and leaders. Change management is an important part of any improvement journey. It can be messy, particularly if the vision and goals are not absolutely clear.

Along the way I will provide you with insight into my perspective on this journey. But first I will review P&W’s past continuous improvement initiatives on their product development process, as they need to be considered when plotting a path to new changes.

P&W’s History of Successfully Implementing Continuous Improvement Initiatives

P&W has a very successful history of implementing continuous improvement initiatives, so much so that Jim Womack, in his book Lean Thinking,2 made note of that success. However, with such success can come a lot of resistance to change. Although establishing “Success is Assured” prior to decision-making represents a dramatic change to existing successful practices, it can also be shown to be a complementary fit to the goals of most of those initiatives. Finding and making visible that alignment can be critical to overcoming the objections to change. Chapter 2 will give general recommendations on that, but this chapter will give some concrete examples for those general recommendations to be built on.

In the early 1990s, I had a manager who liked to start his meetings with a view graph stating:

Equally informed people seldom disagree .

I don’t know where the phrase came from, but I enjoyed watching the reactions of the people in the room. It set the tone for respecting everyone’s point of view, and people seemed more willing to share their ideas. The phrase stayed with me for the rest of my career. It changed how I approached my work and how I dealt with people. I also realized that the success of many of the changes to our product ...