- 538 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Mechanics Of Composite Materials

About this book

This book balances introduction to the basic concepts of the mechanical behavior of composite materials and laminated composite structures. It covers topics from micromechanics and macromechanics to lamination theory and plate bending, buckling, and vibration, clarifying the physical significance of composite materials. In addition to the materials covered in the first edition, this book includes more theory-experiment comparisons and updated information on the design of composite materials.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Mechanics Of Composite Materials by Robert M. Jones in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Mechanics. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

INTRODUCTION TO COMPOSITE MATERIALS

1.1 INTRODUCTION

The objective of this chapter is to address the three basic questions of composite materials and structures in Figure 1-1: (1) What is a composite material? (2) Why are composite materials used instead of metals? and (3) How are composite materials used in structures? As part of The What, the general set of composite materials will be defined, classified, and characterized. Then, our attention will be focused on laminated fiber-reinforced composite materials for this book. Finally, to help us understand the nature of the material we are trying to model with mechanics equations, we will briefly describe manufacturing of composite materials and structures. In The Why, we will investigate the advantages of composite materials over metals from the standpoints of strength, stiffness, weight, and cost among others. Finally, in The How, we will look into examples and short case histories of important structural applications of composite materials to see even more reasons why composite materials play an ever-expanding role in today's and tomorrow's structures.

Figure 1-1 Basic Questions of Composite Materials and Structures

1.2 THE WHAT — WHAT IS A COMPOSITE MATERIAL?

The word composite in the term composite material signifies that two or more materials are combined on a macroscopic scale to form a useful third material. The key is the macroscopic examination of a material wherein the components can be identified by the naked eye. Different materials can be combined on a microscopic scale, such as in alloying of metals, but the resulting material is, for all practical purposes, macroscopically homogeneous, i.e., the components cannot be distinguished by the naked eye and essentially act together. The advantage of composite materials is that, if well designed, they usually exhibit the best qualities of their components or constituents and often some qualities that neither constituent possesses. Some of the properties that can be improved by forming a composite material are

• strength

• stiffness

• corrosion resistance

• wear resistance

• attractiveness

• weight

• fatigue life

• temperature-dependent behavior

• thermal insulation

• thermal conductivity

• acoustical insulation

Naturally, not all of these properties are improved at the same time nor is there usually any requirement to do so. In fact, some of the properties are in conflict with one another, e.g., thermal insulation versus thermal conductivity. The objective is merely to create a material that has only the characteristics needed to perform the design task.

Composite materials have a long history of usage. Their precise beginnings are unknown, but all recorded history contains references to some form of composite material. For example, straw was used by the Israelites to strengthen mud bricks. Plywood was used by the ancient Egyptians when they realized that wood could be rearranged to achieve superior strength and resistance to thermal expansion as well as to swelling caused by the absorption of moisture. Medieval swords and armor were constructed with layers of different metals. More recently, fiber-reinforced, resin-matrix composite materials that have high strength-to-weight and stiffness-to-weight ratios have become important in weight-sensitive applications such as aircraft and space vehicles.

1.2.1 Classification and Characteristics of Composite Materials

Four commonly accepted types of composite materials are:

(1) Fibrous composite materials that consist of fibers in a matrix

(2) Laminated composite materials that consist of layers of various materials

(3) Particulate composite materials that are composed of particles in a matrix

(4) Combinations of some or all of the first three types

These types of composite materials are described and discussed in the following subsections. I am indebted to Professor A. G. H. Dietz [1-1] for the character and much of the substance of the presentation.

1.2.1.1 Fibrous Composite Materials

Long fibers in various forms are inherently much stiffer and stronger than the same material in bulk form. For example, ordinary plate glass fractures at stresses of only a few thousand pounds per square inch (lb/in2 or psi) (20 MPa), yet glass fibers have strengths of 400,000 to 700,000 psi (2800 to 4800 MPa) in commercially available forms and about 1,000,000 psi (7000 MPa) in laboratory-prepared forms. Obviously, then, the geometry and physical makeup of a fiber are somehow crucial to the evaluation of its strength and must be considered in structural applications. More properly, the paradox of a fiber having different properties from the bulk form is due to the more perfect structure of a fiber. In fibers, the crystals are aligned along the fiber axis. Moreover, there are fewer internal defects in fibers than in bulk material. For example, in materials that have dislocations, the fiber form has fewer dislocations than the bulk form.

Properties of Fibers

A fiber is characterized geometrically not only by its very high length-to-diameter ratio but by its near-crystal-sized diameter. Strengths and stiffnesses of a few selected fiber materials are arranged in increasing average S/ρ and E/ρ in Table 1-1. The common structural materials, aluminum, titanium, and steel, are listed for the purpose of comparison. However, a direct comparison between fibers and structural metals is not valid because fibers must have a surrounding matrix to perform in a structural member, whereas structural metals are 'ready-to-use'. Note that the density of each material is listed because the strength-to-density and stiffness-to-density ratios are commonly used as indicators of the effectiveness of a fiber, especially in weight-sensitive applications such as aircraft and space vehicles.

Table 1-1 Fiber and Wire Properties*

* Adapted from Dietz [1-1]

Graphite or carbon fibers are of high interest in today's composite structures. Both are made from rayon, pitch, or PAN (polyacrylonitrile) precursor fibers that are heated in an inert atmosphere to about 3100°F (1700°C) to carbonize the fibers. To get graphite fibers, the heating exceeds 3100°F (1700°C) to partially graphitize the carbon fibers. Actual processing is proprietary, but fiber tension is known to be a key processing parameter. Moreover, as the processing temperature is increased, the fiber modulus increases, but the strength often decreases. The fibers are typically far thinner than human hairs, so they can be bent quite easily. Thus, carbon or graphite fibers can be woven into fabric. In contrast, boron fibers are made by vapor depositing boron on a tungsten wire and coating the boron with a thin layer of boron carbide. The fibers are about the diameter of mechanical pencil lead, so they cannot be bent or woven into fabric.

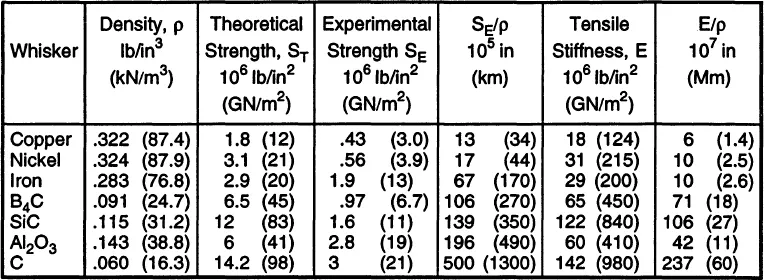

Properties of Whiskers

A whisker has essentially the same near-crystal-sized diameter as a fiber, but generally is very short and stubby, although the length-to-diameter ratio can be in the hundreds. Thus, a whisker is an even more obvious example of the crystal-bulk-material-property-difference paradox. That is, a whisker is even more perfect than a fiber and therefore exhibits even higher properties. Whiskers are obtained by crystallization on a very small scale resulting in a nearly perfect alignment of crystals. Materials such as iron have crystalline structures with a theoretical strength of 2,900,000 psi (20 GPa), yet commercially available structural steels, which are mainly iron, have strengths ranging from 75,000 psi to about 100,000 psi (570 to 690 MPa). The discrepancy between theoretical and actual strength is caused by imperfections in the crystalline structure of steel. Those imperfections are called dislocations and are easily moved for ductile materials. The movement of dislocations changes the relation of the crystals and hence the strength and stiffness of the material. For a nearly perfect whisker, few dislocations exist. Thus, whiskers of iron have significantly higher strengths than steel in bulk form. A representative set of whisker properties is given in Table 1-2 along with three metals (as with fibers, whiskers cannot be used alone, so a direct comparison between whiskers and metals is not meaningful).

Table 1-2 Whisker Properties*

* Adapted from Sutton, Rosen, and Flom [1-2] (Courtesy of Society of Plastic Engineers Journal).

Properties of Matrix Materials

Naturally, fibers and whiskers are of little use unless they are bonded together to take the form of a structural element that can carry loads. The binder material is usually called a matrix (not to be confused with the mathematical concept of a matrix). The purpose of the matrix is manifold: support of the fibers or whiskers, protection of the fibers or whiskers, stress transfer between broken fibers or whiskers, etc. Typically, the matrix is of considerably lower density, stiffness, and strength than the fibers or whiskers. However, the combination of fibers or whiskers and a matrix can have very high strength and stiffness, yet still have low density. Matrix materials can be polymers, metals, ceramics, or carbon. The cost of each matrix escalates in that order as does the temperature resistance.

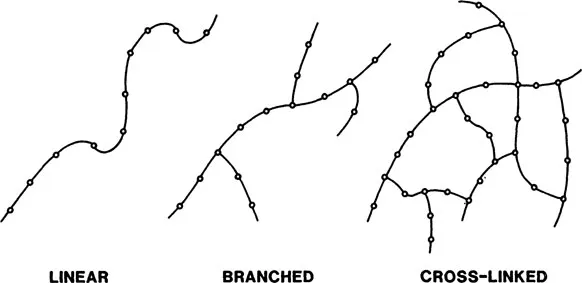

Figure 1-2 Polymer Structure

Polymers (poly ≡ many and mer ≡ unit or molecule) exist in at least three major forms: linear, branched, or cross-linked. A linear polymer is merely a chain of mers. A branched polymer consists of a primary chain of mers with other chains that are attached in three dimensions just like tree branches in Figure 1-2. Finally, a cross-linked polymer has a large number of three-dimensional highly interconnected chains as in Figure 1-2. Linear polymers have the least strength and stiffness, whereas cross-linked polymers have the most because of their inherently stiffer and stronger internal structure. The three main classes of structural polymers are rubbers, thermoplastics, and thermosets. Rubbers are cross-linked polymers that have a semicrystalline state well below room temperature, but act as the rubber we all know above room temperature (remember the Challenger rubber O-rings that failed so catastrophically!). Thermoplastics are polymers that branch, but generally do not cross-link very much, if at all. Thus, they usually can be repeatedly softened by heating and hardened by cooling. Examples of thermoplastics include nylon, polyethylene, and polysulfone. Thermosets are polymers that are chemically reacted until almost all the molecules are irreversibly cross-linked in a three-dimensional network. Thus, once an epoxy has 'set', it cannot be changed in form. Examples of thermosets include epoxies, phenolics, and polyimides. A typical organic epoxy matrix material such as Narmco 2387 [1-3] has a density of .044 lb/in3 (11.9 kN/m3), compressive strength of 23,000 psi (.158 GPa), compressive modulus of 560,000 psi (3.86 GPa), tensile strength of 4200 psi (.029 GPa), and tensile modulus of 490,000 psi (3.38 GPa).

Other matrix materials include metals that can be made to flow around an in-place fiber system by diffusion bonding or by heating and vacuum infiltration. Common examples include aluminum, titanium, and nickel-chromium alloys. Ceramic-matrix composite materials can be cast from a molten slurry around stirred-in fibers with random orientation or with preferred flow-direction orientation because of stirring or some other manner of introducing the ceramic. Alternatively, ceramic matrix material can be vapor deposited around a collection of already in-place fibers. Finally, carbon matrix material can be vapor deposited on an already in-place fiber system. Alternatively, liquid material can be infiltrated around in-place fibers and then carbonized in place by heating to high temperature. The process involving liquid infiltration and carbonization must be repeated many times because carbonizing the liquid results in decreased volume of the matrix. Until the voids can no longer be filled (they become disconnected as densification continues), the potential matrix strength and stiffness have not been achieved.

1.2.1.2 Laminated Composite Materials

Laminated composite materials consist of layers of at least two different materials that are bonded together. Lamination is...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Dedication

- Table of Contents

- PREFACE TO THE SECOND EDITION

- PREFACE TO THE FIRST EDITION

- 1 INTRODUCTION TO COMPOSITE MATERIALS

- 2 MACROMECHANICAL BEHAVIOR OF A LAMINA

- 3 MICROMECHANICAL BEHAVIOR OF A LAMINA

- 4 MACROMECHANICAL BEHAVIOR OF A LAMINATE

- 5 BENDING, BUCKLING, AND VIBRATION OF LAMINATED PLATES

- 6 OTHER ANALYSIS AND BEHAVIOR TOPICS

- 7 INTRODUCTION TO DESIGN OF COMPOSITE STRUCTURES

- APPENDIX A: MATRICES AND TENSORS

- APPENDIX B: MAXIMA AND MINIMA OF FUNCTIONS OF A SINGLE VARIABLE

- APPENDIX C: TYPICAL STRESS-STRAIN CURVES

- APPENDIX D: GOVERNING EQUATIONS FOR BEAM EQUILIBRIUM AND PLATE EQUILIBRIUM, BUCKLING, AND VIBRATION

- INDEX