![]()

1

SUPPLY CHAIN IN A STRATEGIC CONTEXT

1.1 Importance of Supply Chain Performance to the Business

Supply chain performance has a major impact on businesses in terms of

• Price and cost

• Capacity and lead-time response

• Quality and innovation

We need to have a clear view of how much our supply chains can deliver. We need to be able to persuade senior managers to give us the backing and resources we need to deliver supply chain performance that is a major benefit for the business.

1.1.1 Prices and Cost

Businesses that manufacture, have physical operations, or sell retail products usually spend more than half their cost of sales with external suppliers. The financial impact on the business is therefore clear. For example, in a business making a profit of $50 million and spending $250 million, a mere 1% difference in prices (either way) makes a $2.5 million (5%) difference in profit. The price paid to suppliers is therefore important and sometimes very difficult to get right. Changing market conditions, shortages of capacity, changing technology, political issues, and many more factors influence the right price to pay. There is no formula or method for calculating the right price. Competitive quotations, comparisons using price banks, reference to previous prices paid are all useful. Estimating what you should pay is however usually not a precise science. Judgment, experience, and above all communication and hard work are more likely to get closest.

My colleague Crispin Brown attended a meeting between one of the world’s most successful car companies and a supplier. The supplier’s quotation was rejected. Their price was too low! The car company knew the price did not include enough money for the level of investment and innovation expected. Driving the price too low can be detrimental in the medium term. You may harm your supply base. Sometimes you may even be deselected by a customer.

In many organizations, price is the most important supply chain issue. It is very easy to measure. Purchase price variance (PPV) (see Section 8.6) is an almost automatic output from the purchase ledger system. However, associated supply costs can often outweigh price differences. Chinese prices and the cost of sea freight from China to the United States or Europe are comparatively low. However, the total lead-times can be 4–6 weeks, and either lack of saleable product or the need to air freight sometimes results. Few people make an allowance for this type of occurrence in their initial cost models.

In addition to the price, there are a wide range of additional costs such as packaging, transportation, insurance, customs, taxes, warranty, and obsolete inventory. Sometimes these can outweigh the difference in price between different suppliers. For example, if you outsource to Chinese suppliers, but lead time to European or United States customers is crucial, inventory holding costs or airfreight may be more than the price advantage.

The competitiveness of most businesses is highly sensitive to prices and supply chain costs.

* * *

1.1.2 Lead Time and Responsiveness

The control of inventory would be easy if customer demand was constant or lead times were instant. We could order the customer requirements from the suppliers as required and have very little inventory. In reality, fluctuating customer orders and varying lead-times make this a challenging area for supply chain. When combined with the fact that the customers usually expect delivery in a much shorter time than our lead time, large mismatches can result. If customer demand fails to materialize, excess inventory levels can result. The larger the excess inventory, the more likely it will become obsolete. Obsolescence costs hurt businesses quite hard. Perhaps even worse, if demand increases too rapidly for supplier capacity, large shortages of product can occur. Customer confidence may never return. The job of the planners is to maintain the right level of inventory to ensure customers still get their product when demand is high, but that the business is not burdened with high inventory costs when demand reduces. At a more strategic level, the supply chain function must ensure the suppliers have sufficient and flexible capacity to meet foreseeable demand. This requires close cooperation between people in purchasing and logistics roles.

The balance between demand and supply lead time, inventory level, and customer service is a constant struggle in most businesses. Complicated processes and systems for forecasting and optimizing inventory are used. It is an important job to make this process as accurate as possible. However, it will always be wrong to some extent. Reducing supplier lead times is a better approach that makes the planning task less challenging. With work, supplier lead-time reductions are realistic, but this type of initiative often receives too little focus. Using our previous example of the $250 million spent by a business making $50 million profit, a 6-week inventory holding represents nearly $29 million of cash. The cost of cash tied up may be an issue, but it is also likely we will need to dispose of some of it due to obsolescence or shelf life. If we scrap 10% of the 6-week holding it will represent a profit reduction of nearly $3 million or 6%. This is therefore a big business issue.

The example of total cost when shipping from China also illustrates how closely purchasing and logistics need to work together. Methods of planning capacity, scheduling, and shipping product need to be agreed early on in the sourcing of parts from overseas (or even from local suppliers). Integrating the organizational structures of purchasing and logistics can also integrate the thinking, and calling them the supply chain works for me.

When I first joined Ingersoll Engineers as a consultant, inventory reduction was a fairly common project. When we started the Demand Chain International consultancy, we helped one of the large private equity firms to reduce inventory in a series of their acquisitions. These were interesting and rewarding programs because they changed the way the planners and the planning system worked. We introduced approaches such as Kanban where appropriate. We changed the way material requirements planning (MRP) parameters were used. We changed the way the planners did their job. We introduced sales and operations planning. Inventory is both a real burden on cash flow and a provider of customer service. In several programs the savings in cash were in the order of $50 million. While the savings are in cash, not profit, they make a business Lean and healthy. Section 5.5.1 describes an approach to “Inventory Reduction and Optimization.”

Businesses need to work with suppliers for variable capacity, short lead times, and quality.

* * *

1.1.3 Quality and Innovation

You get what you pay for used to be the view. With quality went higher price. However, in many instances the opposite is true. The “quality costs money” myth was disproved by the Japanese in the 1970s and 1980s when it became clear how continuous improvement was enabling them to produce higher quality at low prices. Now that such a high proportion of our products are outsourced, we are highly reliant on our suppliers and we need to work together with them on continuous improvement. Some quality problems are our fault; for example, poorly defined tolerances on drawings, poorly communicated software updates, material specifications from different regions, even units of measure. (We saw a beautifully machined component on a visit to a Japanese factory. Unfortunately it was 25.4 times too small! The drawings failed to specify the dimensions were in inches not millimeters.)

In more complex quality improvement, data needs to be collected, the failures analyzed, causes diagnosed, and solutions developed and implemented. This requires integrated effort right along the supply chain and back to suppliers. For some items, we need to actively source suppliers who have the right attitudes and quality approach, otherwise we will not achieve the quality levels that customers demand. We once had quite complex quality problems with electronic assemblies from a large supplier who offered to “solve the problem” by adding an extra few products free of charge to every container shipment. This would have more than covered the number of failures, but would not have met the costs of administration, additional costs of shipping replacements to our end customers, testing, and especially the customer dissatisfaction. We refused their offer and sourced the product elsewhere. The new source was at a higher price, but lower cost! A view from a price-driven purchasing point of view would have been to source the lower-priced product.

Many competitive technical issues critical to business success are also rooted in the supply base. Many businesses are now integrators of technology and product supplied by others. Makers of airplanes, computers, mobile phones, automobiles, and many other products rely on key suppliers to develop new technology as well as manufacture the product. Some businesses design key parts of their product in-house, but subcontract manufacture to suppliers. The communication between design and manufacture then becomes limited, and knowledge that would aid manufacture, improve quality, and reduce cost is lost in communication from the manufacturer to the designer. This becomes even more important if the technology involved is developing quickly. Printed circuit board (PCB) assembly is a good example of where good progress has been made on this issue. Most people have outsourced their assembly of PCBs because it is specialized work and requires constant investment of time and money in new techniques and equipment. PCB manufacturers quickly realized the need for design rules. They produced guidelines to help the designers of PCBs with component spacing, heat shadows, and board layout issues. However, in most cases, the design of the PCB layout was not a core competence for the customer. Many businesses therefore decided to keep the design of the circuits in-house, but outsource the design layout of the board. Some businesses, especially those that work with leading and more fashion-oriented electronic products, see their core competence as marketing and are heavily reliant on suppliers for the development of new types of screens, communication technology, and electronics. The degree to which you outsource is a key business decision. Few key players in the fashion electronics market do much of their own manufacturing. However, because they outsource such a significant amount, they are careful to choose a good partner and get the relationship and understanding right.

The value of supplier contribution to engineering, design, marketing information, and quality improvement is difficult to assess. Somehow, the job of the supply chain is to include all the necessary factors into the assessment and management of suppliers—from selection and appraisal to schedule management and even to obsolescence.

Traditional approaches that we still see in many organizations include sourcing on price, relying on the leverage of one supplier against the other, using traditional legal contracts to set-out the business relationship, and keeping suppliers at a safe distance. These traditional approaches won’t deliver the best performance from the supply chain. Where old attitudes exist, we need to change them. Our businesses need the most competitive advantage our supply chain can get for them!

Businesses need to work with their key suppliers to develop, design, and supply new technology.

* * *

1.2 Scope of the Supply Chain

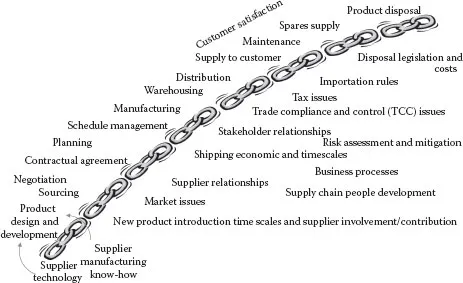

Figure 1.1 uses the rather overused supply chain picture, for which I apologize. However, it does show that the number of supply chain issues to be managed along the route to the customer is astounding.

A large range of issues need to be managed along the supply chain. Many of the issues seem to be outside the scope of the supply chain. Forecasting customer priorities and demand patterns, for example, normally belong to sales and marketing, and so they should. However, involvement and understanding of the demand side issues from the supply chain are an essential starting point for good customer service and profitability.

We see many businesses where the supply chain still does not start early enough in the development of new products, does not include all the areas of responsibility it should, or finishes before the customer has been satisfied or suppliers have been paid.

New product designs rely on design engineers to look for the appropriate new technology, but the supply chain should also be looking for these opportunities. Visiting suppliers and technology shows with engineers is a good use of some supply chain time. This is also a way to check what the engineers are doing and make sure they aren’t doing things they shouldn’t—for example, making sourcing commitments. This can help to find the best potential new developments in the supply base.

Figure 1.1 Scope of the supply chain.

One company we know well designs and markets electronic products. The manufacturing is entirely outsourced—and so too is a large part of the more detailed design work. Experience has proved that the people who will manufacture the product can detail designs that will be more “manufacturable,” such as

• Plastic moldings with features, material thicknesses, and draft angles that will work in the mold tools

• PCBs that are efficient to pick and place, work well in reflow, and use components common with other production

• Machined items which use, for example, material specifications that can be sourced from Chinese mills if required, have understandable tolerances and are more easily manufactured using the machine tools available

It is essential that a good process is in place to select the right suppliers early in the product design process. The process is likely to include supply chain people working with sales and marketing as well as engineering and design people.

Some of the best businesses trawl for new suppliers using their supplier portal. Potential suppliers can express an interest and after completion of a nondisclosure agreement, they can present their capabilities. Potential suppliers can then be examined to see what they offer.

Working along the supply chain, sales and operations planning (S&OP) is an example of a supply chain process that is of fundamental importance to the business and involves senior people from every function. Examining forecast uncertainties, looking for supply chain options to minimize risks, and trying to optimize the balance of supply and demand is critical and quite difficult. Senior sales and marketing, operations and even finance ...