- 616 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

In the view of many power experts, distributed power generation represents the paradigm of the future. Distributed Power Generation: Planning and Evaluation explores the preparation and analysis of distributed generators (DGs) for residential, commercial and industrial, as well as electric utility applications. It examines distributed generation versus traditional, centralized power systems, power demands, reliability evaluation, planning processes, costs, reciprocating piston engine DGs, gas turbine powered DGs, fuel cell powered DGs, renewable resource DGs, and more. The authors include recommendations and guidelines for DG planners, and numerous case studies illustrate the discussions.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Distributed Generation versus Traditional Power Systems

1.1 INTRODUCTION

Distributed generation, or DG, includes the application of small generators, typically ranging in capacity from 15 to 10,000 kW, scattered throughout a power system, to provide the electric power needed by electrical consumers. As ordinarily applied, the term distributed generation includes all use of small electric power generators, whether located on the utility system, at the site of a utility customer, or at an isolated site not connected to the power grid.

By contrast, dispersed generation, a subset of distributed generation, refers to generation that is located at customer facilities or off the utility system. Usually, dispersed generation is also understood to include only very small generation units, of the size needed to serve individual households or small businesses, in the capacity range of 10 to 250 kW.

Most types of distributed generators utilize traditional power generation paradigms -- diesel, combustion turbine, combined cycle turbine, low-head hydro, or other rotating machinery. But in addition, DG includes fuel cells and renewable power generation methods such as wind, solar, or low-head hydro generation. These renewable generators are often lumped into the “DG” category because their small size makes them very convenient to connect to the lower voltage (distribution) parts of the electric utility grid.

1.2 DISTRIBUTED VERSUS CENTRAL STATION GENERATION

The bulk of electric power used worldwide is produced at central station power plants, most of them utilizing large, fossil-fuel combustion or nuclear boilers to produce steam that drives steam turbine generators. A majority of these central station generators are between 150,000 and 800,000 kW maximum output. This makes them relatively large, in terms of both physical size and facilities’ requirements, and often making site selection and procurement a real challenge. Usually, two or more generating units (boiler-turbine-generator combinations) are clustered together at a generating plant, in order to share the switching, operating, fuel loading and other facilities that must be included, thus lowering the cost per unit of generation.

Perceived Cost Advantages Of DG Units

The plant efficiency of most existing large central generation units is in the range of 28 to 35%, meaning that they convert between 28 to 35% of the energy in their fuel into useful electric power. By contrast, efficiencies of 40 to 55% are attributed to small fuel cells and to various “hi-tech” gas turbine and combined cycle units suitable for DG application. In many cases, claims of efficiencies over 45% are impractical, based upon somewhat unrealistic operating assumptions. But in any case there is little doubt that modern DG units can achieve efficiencies that equal or exceed the average performance of the existing utility central station generation infrastructure.

Part of this comparison is “unfair.” The DG units being discussed are modern units utilizing recently perfected “hi-tech” materials and incorporating advanced designs that minimize wear and required maintenance and include extensive computerized control that reduces operating labor. By contrast the existing electric utility infrastructure of central station generators is on average over 20 years old, with much of it 50 years old. Older systems = lower technology = lower performance. But the “fairness” of this comparison hardly matters to a businessman who is paying 13¢/kWhr for power from his local utility, and discovers he can buy his own distributed generation system and produce it himself, at his place of business, for 10¢/kWhr.

Physics is still on the side of the larger generator

The fact that small, modern generators can be more efficient and less costly to operate than large, old generators, has led some people to conclude incorrectly that there is no longer an economy of scale in power generation. This is nonsense. While modern DG units are potentially more efficient than old central station generators, the simple fact is that given equivalent levels of technology and the same type of design, physics will always favor the larger generator. There are two ways to look at this:

Size improves thermal efficiency. Most power generators use some sort of thermal cycle to convert fossil or solar power to electricity. The thermal efficiency of a larger unit will always be better, because there are no significant physical processes involved in the conversion, containment, or channeling of energy in electric power generation that do not enjoy some type of economy of scale. Simply put, physics is always on the side of the larger generator. Whether boiler or fuel cell, if one takes a particular design and increases its size in all three dimensions by two, its internal volume (and hence generation potential) increases by a factor of eight, while its surface area (and hence its potential for heat loss) increases by only a factor of four. The ratio of heat loss to unit size decreases, improving the unit’s potential efficiency.

Similar relationships exist for most other physical processes including those used in gas and steam turbines, heat exchangers, and exhaust recirculation. In addition, trapping waste heat, an important part of the high efficiencies quoted for many DG units, is more efficient at a larger scale. Nearly always, the larger unit has the theoretical edge.

However, in many DG technologies – fuel cells, small turbines, and solar units in particular – the relative advantage of large versus small is not nearly as great as it was in an age when boiler technology was the guiding rule determining generator efficiency. Modern technology has made physics less of the overwhelming advantage it once was.

One can always “double up” units to lower cost. Even if there were no economy of scale in the physical processes mentioned above, one could usually obtain a noticeable economy of scale by just assembling multiple units of the same type at one site. For example, if one fuel cell of a certain size and type costs $X per kW, two identical units built together at that same site will cost less than $2X. While the units themselves have the same net efficiency as one unit, some facility costs such as those for insulation, DC-AC conversion, protection and control, can be shared, lowering capital and maintenance costs.

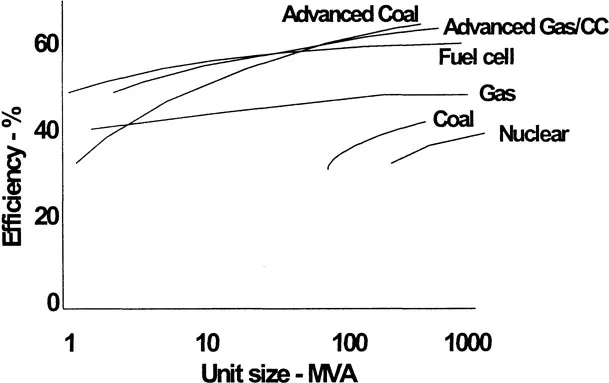

The net effect of the above is that a large modern power generation unit will be slightly more efficient and less costly per kW than a small modern DG unit built with the same technology, usually beating it by a noticeable margin. For example, high-inlet-temperature pressurized, gasified-coal central station generators, of about 600 MW output, are projected to have net efficiencies over 50%, and several types of combined-cycle pulverized-coal steam generator designs are projected to exceed 60% efficiency (it remains to be seen if this level can be reached). These efficiencies exceed the projected net efficiencies of all types of small generators, whether gas turbine, combined cycle, or fuel cell.

However, the real issue isn’t efficiency. It is total operating cost. There is every evidence that with respect to that attribute, a slight economy-of-scale in generation units will continue for the foreseeable future (Figure 1.1). In some cases, the margin of improvement in efficiency as size increases becomes insignificant once a certain size is reached (e.g., 50 MW), and several practical concerns militate against incredibly large units. But given the same basic technology, a large generator will always produce power at an equal or lower cost per kilowatt than a smaller one. But, as will be shown in a few pages, low production cost alone may not be enough to make it competitive against DG.

Figure 1.1 Best estimates of the realizable average lifetime maximum fuel efficiency for various technologies of generation as a function of unit size show a definite economy of scale in all cases. This data was developed by the authors from technical and marketing literature about generating units available to the power industry.

A Shrinking Economy of Scale

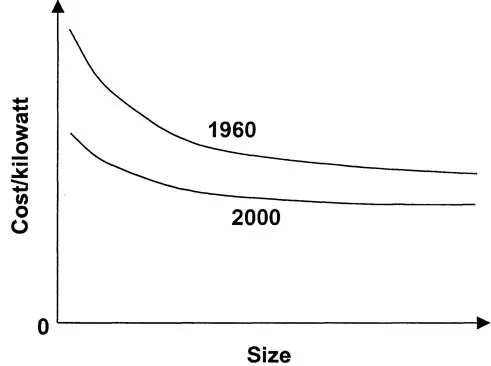

While large modern generators have a fuel economy advantage over small modern generators, it isn’t the overwhelming advantage that larger generators had during the period most power systems were built. Technological advance has improved smaller generator designs more than larger, as illustrated in Figure 1.2. While very large generators once had as much as a 60% advantage over small generators, at the close of the 20th century that advantage has been cut in half, being much closer to 30%. There are four reasons for this change:

Technological advance in fuel conversion has improved the economy of small units more than larger units. No single development is responsible. Instead, it is a general trend cutting across all facets of technology. But two items deserve special mention. First, the development and continued improvement of gas turbines resulted in a new type of generator that has far less economy of scale (i.e., large gas turbines slightly outperform large steam turbine plants, but small gas turbines, while less efficient than their larger siblings, vastly outperform small steam plants). Particularly as long as natural gas remains plentiful with respect to demand, and low in cost, gas turbines will be the generator type of choice for most new generation, both large central station, and medium size (large DG), due to their combination of low initial cost (below $300/kW for larger sizes) and high fuel efficiency (up to 40%, in actual operation, for certain types of advanced Cheng-cycle gas turbines). Smaller gas turbines only achieve efficiencies in the 30% range, but that is still quite good, considering their size gives them potential utilization as DG units.

Figure 1.2 Although there is still a considerable economy of scale in cost, the advantage that a large generator had over a small one constantly shrank during the last half of the 20th century, as technological advance tended to improve small-generator performance more than that of larger units. Coupled with the increasing proportion of costs that must be devoted to T&D (see text) this trend was more than enough to make DG competitive against larger generators in many situations.

Second, vast improvements have been made in heat containment (insulation) and thermal engineering, a subject that is more and more critical to performance, the smaller the design of the generator. For example, the design and production of efficient and low cost heat recuperators (just one of several technological features that give modern micro-turbine generators competitive levels of fuel efficiency) would have been unfeasible in the 1960s.

Shifts in fuel price. Overall, when adjusted relative to other costs such as equipment, labor, emissions control, transmission and distribution (T&D), etc., fuel has dropped in cost, which has cut the importance of the fuel economy advantages that larger machines have. Where once fuel constituted the majority of costs in all cases, and up to 80% of cost in some cases, at the turn of the century, fuel averages only about 40% of total cost in the lifetime evaluation of many small generating units and no more than about 55% of that for large, low initial cost units.

Automation and control. Modern computerized control systems and remote data communications and monitoring technologies mean that many generating units can be automatic and self-operating. As a result, an on-site human operator is not needed in order to assure safe, reliable, and efficient operation, and even periodic maintenance and inspection needs are greatly reduced.

This has drastically changed the economy of scale in power production. In 1950, a 600,000...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Series Introduction

- Preface

- 1 Distributed Generation versus Traditional Power Systems

- 2 Demand for Electric Power

- 3 Reliability and Reliability Evaluation

- 4 Planning and the Planning Process

- 5 Cost and Economic Evaluation

- 6 Reciprocating Piston Engine Distributed Generators

- 7 Gas Turbine Powered Distributed Generators

- 8 Fuel Cell Powered Distributed Generators

- 9 Renewable Resource Distributed Generators

- 10 Energy Storage for Use with Distributed Generation

- 11 Distributed Generation Systems: Planning and Comparison

- 12 Basic DG Case Examples: What to Include and How

- 13 Basic DG Cases: Modularity and Reliability and Cost

- 14 Basic DG Cases: Grid Interconnection Options

- 15 Basic DG Cases: Schedule and Operating Characteristics

- 16 Basic DG Cases: Reliability, Maintenance, and Availability

- 17 Basic DG Cases: Renewable Resource Generation

- 18 Detailed DG Case and Sensitivity Study

- 19 Business Factors and Their Influence on DG Value

- 20 Objectivity and Bias in DG Planning and Evaluation

- 21 Recommendations and Guidelines for DG Planners

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Distributed Power Generation by H. Lee Willis in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Civil Engineering. We have over one million books available in our catalogue for you to explore.