- 304 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

20 Keys to Workplace Improvement

About this book

20 Keys has helped many manufacturing companies integrate the top manufacturing improvement methods into a coordinated system for drastic and continual improvement in involvement, quality, and productivity. This program provides the strategies necessary to achieve ambitious goals through a five-level scoring system.

The revised edition is improved with upgraded criteria for the five-level scoring system to guide your company to world-class status. New material and updated layout make implementation even easier. Two valuable case studies demonstrate effective use by both a Japanese company and an American manufacturer.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access 20 Keys to Workplace Improvement by Iwao Kobayashi in PDF and/or ePUB format, as well as other popular books in Business & Operations. We have over one million books available in our catalogue for you to explore.

Information

Key 1

Cleaning and Organizing

One might expect to start with Key 2's “Rationalizing the System/Management of Objectives.” However, 4S activities (referring to the initials of the Japanese words for various aspects of standardized industrial housekeeping) are a critical foundation for success in the other 19 keys. 4S is therefore rightfully Key 1.

The first two 4S elements, cleaning and organizing, are an issue in every workplace. Even though cleaning and organizing are basic to good working conditions, they are seldom implemented thoroughly, so problems remain. Even when the process of maintaining a clean and organized workplace has been simplified, there's an oversight here, a shortcut there, and soon workplace conditions are as bad as ever.

The 20 Keys approach solves this problem by making the 4Ss something workers want to do to make their work easier rather than something they perceive as being forced upon them. Workplace employees should plan how the 4Ss will be implemented by discussing what currently makes their work harder and what can be done to make it easier. This helps build a common awareness of 4S issues.

When implementing the 4Ss, it is important to make solid improvements one level at a time, such as from level one to level two or level two to level three. The 20 Keys approach starts and ends with the 4Ss. Once the 4Ss have been implemented, it is easier to implement the other 19 keys. Conversely, as progress is made in the other keys, it becomes easier to maintain the 4Ss. Remember—it is vital not only to implement the 4Ss but also to maintain them to prevent backsliding.

Level One

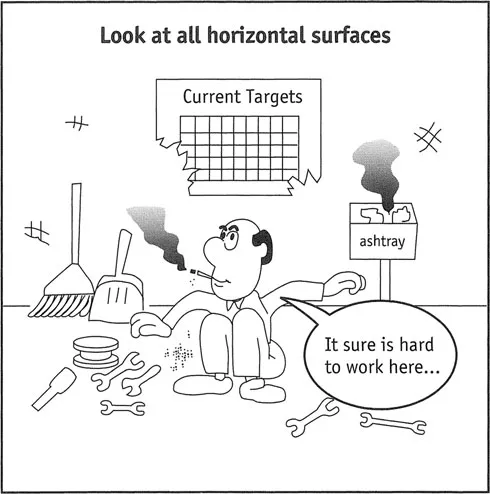

Cigarette butts, scrap paper, and tools and parts are left scattered.

Even today, there are many companies with messy workplaces. If you look at workplaces that managers claim are litter-free, other forms of litter can still be found—they need to rethink what “litter” really means. What about tools, jigs, manuals, and even machines and equipment that remain on site even though they haven’t been used in months or years? Such items should be stored or disposed of.

When I inspect workplaces for unnecessary clutter, I often find signs that are outdated or worn and dirty. When such signs stay up, people are unlikely to notice the newer signs.

When surveying offices, I have come across plenty of desks covered with an untidy array of books, pens, and papers. When I see a desk like that, I know that its owner wastes time looking for things. Some desks hold overflowing ashtrays, with some long-forgotten papers underneath. Boxes are piled with books stacked on their sides so their titles cannot be read. Workplaces like this are definitely ranked “level one.”

Level Two

Dispose of unneeded items.

Keep the floors clean.

At level two, the workplace might appear neat and clean at first glance, but if you look around you’ll find an amazing amount of unneeded items piled on desks, shelves, and/or machines. Such workplaces need to be gone over: ask whether each item is scheduled for use today or, at most, within the next week. If it will not be used by then, move it out or get rid of it. It is better to store such things elsewhere, even though they may have to be brought back sometime. Anything that has gone unused for even one month should be treated as unneeded. In offices, that includes extra pencils and erasers that accumulate in desk drawers. If you gather up all these extra items (extra usually means “more than one”), you will be amazed at the huge stockpile of usable supplies that results.

Also at level two, work-in-process (WIP) and tools are piled neatly, but the piles are right on the floor. This means that before these items can be used, someone has to bend over and pick them up. They are also difficult to move elsewhere and therefore tend to get in the way. Getting rid of all floor piles is one way to make work easier.

Important Points

• Don’t leave items on the floor.

• Get rid of things that will not be used soon.

Problems at Level Two

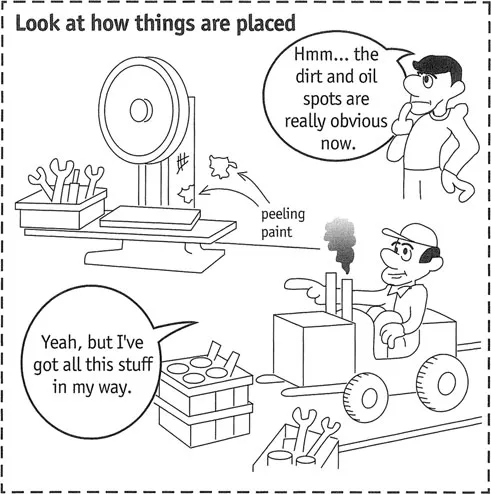

Look at how things are placed.

The workplace is now at level two, but if you look at the corners, especially where the floor meets walls or pillars, you will find unneeded items, dirt, or dust. Such items are also likely to accumulate along or behind large equipment units. Notice also that pathways are not outlined and so piles of stuff stick out into walking or transport paths.

Perhaps some white tape or paint was once used to mark pathways but over time the markings have worn away in places. Or maybe your workplace is supposed to be all “work area” with no marked pathways. All workplaces should have well-marked pathways. Plan a new layout and make some pathways as soon as possible.

You can probably find some work-in-process or empty boxes that are poorly organized. If products, WIP, tools, or other items are in cartons sitting directly on the floor, move the cartons to a position that makes them more easily accessible.

In offices, the power cords and cables from computers, fax machines, copiers, and other equipment can be found all over the backs or sides of desks like well-tossed spaghetti. Instead, they should all be bundled and routed inconspicuously.

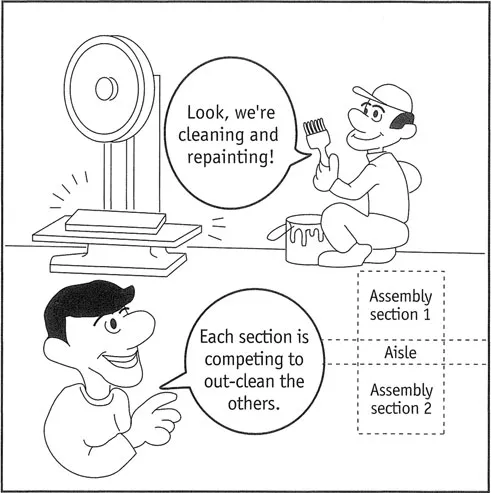

Level Three

Clean up equipment, Mark pathways and clear out the corners.

Have the employees paint all parts of the walls and pillars that can be reached by hand (up to about six and a half feet). Painting requires cleaning off dirt and dust. Use a bright color so that everyone can stand and see fresh new paint all around them at eye level. If it takes two or three coats of paint to get the workplace looking bright and clean, so be it. The equipment should be sparkling clean and spotless: clean equipment is easier to maintain and less likely to break down.

Make special-purpose carts or pallets to hold various kinds of work-in-process. These carts or pallets should not be stored randomly, but should have clearly assigned, well-planned places. Design them so that it is easy to take items off and put them back in the right place. If items need to go in at certain angles, indicate those as well.

Important Points

• Clearly determine and mark off areas that each work group is responsible for (including pathways).

• Have regular “check-up inspections” where work groups engage in friendly competition to be the best.

Problems at Level Three

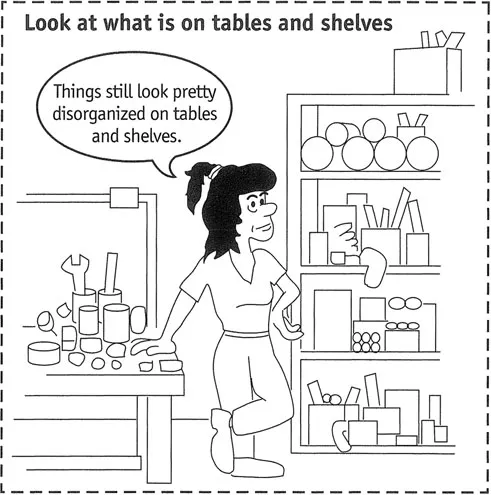

Look at what is on tables and shelves.

Now pathways are clear and distinctly marked and the floors and walls are also clean. However, tabletops, cabinets, and shelves are still cluttered with a hodgepodge of parts, tools, rags, gauges, books, and other items. There are no clearly marked places for work-in-process, and sometimes it is hard to find needed tools.

Open the doors of storage cabinets and what do you find? Chances are that a lot of unused stuff has been crammed in there. The rationale in locking things away is that they will be safe there. But it is more important to create a workplace where tools can be easily found and retrieved.

Level Four

Clearly organize and mark all sections using right angles and parallel lines.

Organize storage areas for each workstation.

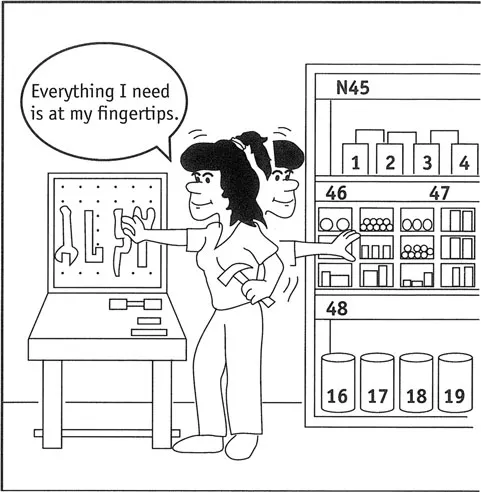

Use labeling, numbering, or color-coding to indicate exactly which tools (or jigs, parts, gauges, cleaning supplies, etc.) go where. This makes these items easy to find and put back correctly. Organize items neatly, using right angles and parallel lines wherever possible. Keep high-use tools, gauges, and the like within easy reach. Organize items on shelves by function and mark them so anyone can tell what any machine, part, tool, or manual is used for. In offices, this applies to filing systems: Files should be easy for anyone to locate.

Remove doors from cabinets so contents are always visible. The contents should be well organized and labeled. Set up special carts to hold work-in-process and tools on visible shelves so workers can find and retrieve items within three seconds.

In a level-four workplace each person can work easily and efficiently, with a minimum of motion needed to pick up parts, tools, and other items.

Important Points

• Organize tools and parts separately for each workstation.

• Use a labeling, numbering, or color-coding system for shelf storage.

Problems at Level Four

Make sure the wo...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Dedication

- Table of Contents

- Publisher’s Message

- Preface

- Introduction

- Key 1: Cleaning and Organizing

- Key 2: Rationalizing the System/Management of Objectives

- Key 3: Improvement Team Activities

- Key 4: Reducing Inventory (Shortening Lead Times)

- Key 5: Quick Changeover Technology

- Key 6: Manufacturing Value Analysis (Methods Improvement)

- Key 7: Zero Monitor Manufacturing

- Key 8: Coupled Manufacturing

- Key 9: Maintaining Equipment

- Key 10: Time Control and Commitment

- Key 11: Quality Assurance System

- Key 12: Developing Your Suppliers

- Key 13: Eliminating Waste (Treasure Map)

- Key 14: Empowering Workers to Make Improvements

- Key 15: Skill Versatility and Cross-Training

- Key 16: Production Scheduling

- Key 17: Efficiency Control

- Key 18: Using Microprocessors

- Key 19: Conserving Energy and Materials

- Key 20: Leading Technology and Site Technology

- Postscript: Implementing the 20 Keys

- Appendixes

- About the Author

- Index