![]()

Part I

Fifty Examples of Quadrupling Resource Productivity

![]()

Chapter 1

Twenty Examples of Revolutionising Energy Productivity

People used to talk about ‘saving energy’. The phrase had a moralistic connotation. Father would admonish his children to switch off lights when leaving a room and never to let motors or appliances run when not needed. After all, besides costing money, wastefulness was a sin. When a demand for environmental protection became widespread, the reaction on the part of governments, electric power suppliers and some environmental leaders was not particularly imaginative: You (childish and demanding folks) can get as much environmental protection as you want if you are prepared to reduce your demands radically. The simplistic notion of saving energy by voluntarily making do with less allowed leaders to avoid really grappling with the energy issue in a creative way.

In recent years, a new expression has emerged: the ‘rational use of energy’. Use of this term enhances the speaker’s reputation by suggesting an expertise in energy matters. So we may hesitate to reject this term, yet we aren’t happy with it either. It sounds so bureaucratic, complicated and defensive. It doesn’t convey any enjoyment and is not straightforward in talking about the relationship between energy use and technological progress.

Technological progress is what this book is all about. Or, rather, it is about redirecting technological progress. Thus we prefer to speak of ‘energy productivity’.

Taken by itself, and depending on your circumstances, the term ‘productivity’ can have positive or negative connotations. These mixed connotations spring from the disservice of economists who have narrowed down the term to mean only labour productivity. In the past, labour productivity was a good thing meaning prosperity. Today, labour productivity is inevitably associated with the threat of unemployment.

Energy productivity, on the other hand, is something everybody can greet with joy. Virtually nobody stands to lose by it.

This chapter is about increasing energy productivity by a factor of four. The expressions ‘energy savings’ or ‘rational use of energy’ are simply inadequate to convey the appropriate sense of joyous attack on our prevalent technological dinosaurs. The concept of ‘energy productivity’ is more equal to the task.

By using Factor Four as a standard, we might at first appear to be excluding much of the manufacturing world: smelting to produce aluminium metal cannot, given the laws of thermodynamics, be made four times more energy-efficient. The same holds for producing chlorine, cement, glass and some other basic materials. But we need not give up on the Factor Four potential of these materials. Aluminium and glass are superbly recyclable, and such recycling would save most of the energy otherwise required to produce them from virgin materials instead. For some end uses, some materials can be substituted for others, with no damage to the manufacturing sector; or materials can be used more judiciously. On a life-cycle basis a factor of four in energy productivity should therefore be available for most end-use services involving metals or glass.

In this book, however, we concentrate on examples with a straightforward potential of multiplying energy efficiency by four or more. We begin with an example that has overwhelming importance for the world’s energy balance.

1.1 HYPERCARS: ACROSS THE US ON ONE TANK OF FUEL*

From 1973 to 1986, the average new US-made car became twice as efficient, from 13 to 27 miles per US gallon (17.8–8.71/100 km). About 4 per cent of the savings came from making cars smaller inside, 96 per cent from making them lighter and better; 36 per cent came just from cutting out the most obviously excessive weight. Since then, however, fuel efficiency has risen by only another 10 per cent or so, and as recently as mid-1991, automakers were claiming that by the end of this century only another 5–10 per cent would be feasible without exorbitant cost or sluggish performance.

CAN’T WE DO BETTER?

The modesty of this claim seemed odd for two reasons. First, many improvements that were used in some mass-produced and well-selling cars were still not being included in many others. Analysts found that the complete adoption of just 17 such widely accepted measures could save another 35 per cent of the fuel used by, say, the average 1987 new car without changing its size, ride or acceleration in any way. The list emphasised such commonplace options as front-wheel drive, four valves per cylinder, overhead cams and five-speed overdrive transmission. It didn’t even include some blindingly obvious items such as retracting brake calipers (as motorcycle brakes do) so that they wouldn’t drag on the disc and try to stop the car whilst the driver was trying to make it go. And on a conservative estimate, this improvement to 44 mpg (5.36 1/100 km) would cost only 53 cents per saved gallon (14 cents per litre) — less than half today’s lowest-ever petrol price in America, where petrol is priced lower than bottled water.

Even as automakers were challenging those analyses, Honda underscored the point by releasing its 1992 VX subcompact, which saved even more — 56 per cent, to 51 mpg or 4.62 1/100 km — and even more cheaply (the bigger saving still cost only 69 cents per gallon or 18 cents per litre). In fact, that Honda car was 16 per cent more efficient than the US National Research Council’s ‘lower-confidence’ estimate, issued several months later, of what will be technically feasible for a subcompact car in 2006!

If that overtaking of prediction by events felt like a time warp, the second reason to think we could do better was positively déjà vu. Whatever exists is possible. But almost unnoticed, automakers in the mid-1980s had already created about a dozen concept cars that combined excellent but fairly conventional components in conventional ways to demonstrate doubled or tripled fuel economy. These four-to five-passenger cars achieved 67–138 mpg (1..5 1/100 km) with normal, and often better-than-normal, safety, emissions and performance. At least two versions, from Volvo and Peugeot, would reportedly cost about the same to mass-produce as today’s cars. However, American automakers paid little attention because the concept cars were generally made in Europe or Japan, and so could be assumed to be somehow too different.

By mid-1991, building on these foundations, a far more radical notion was taking shape at Rocky Mountain Institute (RMI). Why not redesign the car from scratch? Why not rethink it from the wheels up, making it radically simpler? Einstein said that ‘everything should be made as simple as possible — but not simpler.’ Cars, however, had gradually become incredibly baroque, piling one addon gadget atop another to solve problems that better design should have prevented in the first place.

BACK TO BASICS

Examining the basic physics of cars led to a startling conclusion: the extraordinarily able engineers in Detroit, Wolfsburg, Cowley and Osaka had become so specialised that they knew almost everything about almost nothing; so specialised that scarcely any of them could design a whole car by themselves. Crucial integration between design elements was getting lost. There was too much thinking about little pieces, too little about the car as a system. The industry had lost sight of whole-system engineering with meticulous attention to detail — engineering that is extremely simple, and therefore difficult.

In fact, the auto industry was designing the whole car back-wards. After decades of devoted effort, 80–85 about per cent of the fuel energy was getting lost before it could get to the wheels, and only about 1 per cent ended up moving the driver! Why? Because the car was made of steel, which was heavy, and accelerating something so heavy needed an engine so big that it was almost idling most of the time, using such a tiny fraction of its power that its engine became only half as efficient. The industry’s answer was to put ever more effort and complexity into wringing slightly more efficiency from the engine and transmission (the ‘driveline’). Impressive progress was and continues to be made, but the savings are small and the required effort immense.

But look at the car the other way round. What happens to the 15–20 per cent of fuel energy that does sneak through to the wheels? In level urban driving, about a third heats the air that the car pushes aside (rising to 60–70 per cent at highway speeds), a third heats the tyres and road, and a third heats the brakes. But

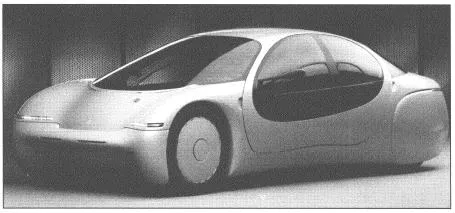

Figure 2 Towards the ‘hypercar’ A General Motors team built two four-passenger Ultralite concept cars in a mere 100 days.

(© General Motors Corporation)

every unit of energy saved from those three fates would in turn save about five to seven units of fuel energy that would no longer have to be fed into the engine in order to deliver that unit of energy to the wheels! Thus, rather than focusing on how to sweat out the next tenth of a per cent of losses in the driveline, designers should treat its inherent inefficiency as a way to multiply energy saved by making the car fundamentally more efficient.

THE ULTRALIGHT STRATEGY

Ways to do this were not hard to find. Using ultrastrong yet crashworthy materials, chiefly advanced composites, could make the car about three times lighter — as little as 1000 lb (473 kg), ready to receive four to five passengers. Better design could make its sleek, moulded shape two to six times more slippery aerodynamically. Better tyres, with less weight pushing down on them, could cut tyre losses three- to fivefold. The car would be designed less like a tank and more like an aeroplane.

This ‘ultralight’ strategy had already been demonstrated. Indeed, at the end of 1991, General Motors showed a four-passenger carbon-fibre Ultralite concept car with doubled efficiency, excellent safety and cleanliness, great comfort and styling, and very sporty performance (0–100 km/h in 8 seconds, 0–60 mph in 7.8 seconds) — comparable to the acceleration of a 12-cylinder BMW, but with less engine (111 hp, 83 kW) than a Honda Civic. Fifty GM experts had built two Ultralites in a mere 100 days.

This and other experiments showed how very light, slippery construction could make a very attractive car 2–2.5 times more efficient than normal.

HYBRID-ELECTRIC DRIVE

Meanwhile, other experiments, mainly in Europe, had shown that a ‘hybrid’ electric propulsion system could boost efficiency by per cent, partly by electronically recovering up to 70 per cent of the braking energy, temporarily storing it and then reusing it for hill climbing and acceleration. The car would get its energy by burning any convenient liquid or gaseous fuel in a tiny onboard power plant of any kind (engine, gas turbine, fuel cell etc.). Fuel is a better way to carry stored energy than electric batteries, which have less than 1 per cent as much useful energy per pound. That is why battery cars, as Dutch car expert Dr P. D. van der Koogh says, are cars ‘that carry mainly batteries, but not very far and not very fast — otherwise they would need to carry even more batteries.’

As RMI’s analysts examined the state of the art, they noticed something extraordinary: artfully combining the ultralight and hybrid strategies could raise efficiency not two-to threefold, as one might expect, but about fivefold. It was like finding an equation that said two plus one equals five. Soon, however, the main reasons for this magical synergy were understood:

weight savings snowball, because the lighter the car becomes, the more components become not only smaller but also ...