![]()

Managing for Shaping the Future | 1 |

IMPROVEMENT, INNOVATION, AND TRANSFORMATION

Improvement, innovation, transformation, renewal, and change—the list goes on, In this book, we don’t plan to be confused by terminology. Instead, we will define key words at the onset, keeping them as simple as possible.

Let’s start with transformation. Transformation occurs when people inside an organization realize they have reached a higher level through continuous improvement and technological innovation. While improvements are the individual actions required to achieve transformation, transformation is the state that results from such improvements. From this standpoint, I agree with Professor Dan Dimancescu, who points out that continuous improvement has been a key factor in the transformation of Chrysler Corporation (Dimancescu 1994).

Now let’s move on to improvement and innovation. The prevailing image for improvement is small change, while innovation refers to breakthrough. Although in general these definitions hold true, it’s not always easy to draw a clear line between improvement and innovation. They are interrelated. Sometimes, after basic technology is developed through continuous improvement, innovations flourish. On the other hand, the application of innovative technologies may create the need for improvement activities.

In this book, improvement is used in a broad, generic sense, which often includes innovation. So please don’t take improvement to mean only small changes in the workplace.

MANAGEMENT MUST ALWAYS TRANSFORM

The success of management is determined by creativity and teamwork at all levels of the organization. Such creativity and teamwork, of course, need to focus on keeping pace with the speed of innovation and change in the external environment. In response to change, many companies all over the world have been striving for companywide transformation. With their own methods and styles, some have achieved significant success while others are still working to get there. To ensure achievement of long-lasting results, it’s necessary to clarify the purpose of companywide improvement and transformation. Indeed, countless numbers of improvement and implementation methods for companywide transformation have been introduced in the market. Unfortunately, with so much at their fingertips, people often jump into the how to before they clearly understand the why.

Table 1-1.

Purposes and Assessment of Companywide Improvement and Transformation

Purposes | Assessment Targets | Assessment Indicators |

1. Significant contribution to achieving the business/profit plans

(Securing profit) | Results | • Performance vis-à-vis business plans (e.g., performance indices of achieving sales turnover, profit margin, and business plans) • Management indicator trends (e.g., sales growth rate, sales profit ratio, profit rate, labor productivity, sales at breakeven point) |

2. Accumulation and standardization of know-how learned from the improvement process, which enables human resources and technologies to develop

(Strengthening improvement and development capability) | Processes | • Accumulation of intrinsic technologies* (number of technological standards, research papers, and patents) • Accumulation of management technologies** (amount of standardized know-how and quality index of know-how) |

What would you say if a junior member of your company asked, “Why do we have to implement companywide improvement?” My explanation is summed up in Table 1-1, which shows the purposes of companywide improvement, as well as the measures needed to assess company progress toward those purposes

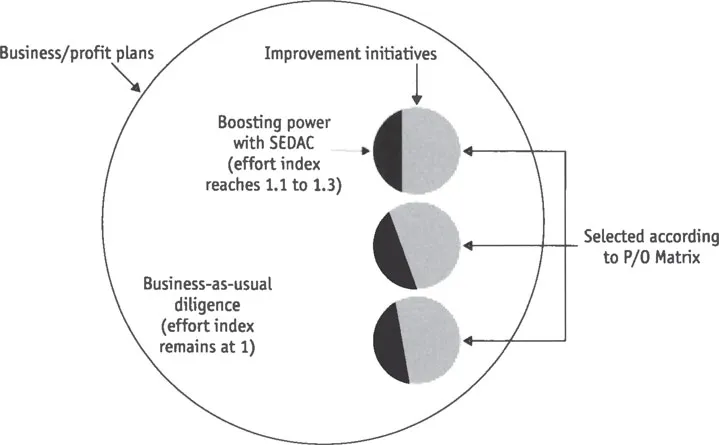

Securing Profits

Obviously, one of the main reasons for companywide improvement is to achieve the company’s business/profit plans. In Figure 1-1, the outer circle represents a company’s business plans, which are translated into daily business activities for making profits. The inner circles represent companywide improvement initiatives, which focus on daily business activities that greatly contribute to achieving business plans. Other aspects of Figure 1-1 will be explained later. Our intent here is to point out that improvement initiatives are part of the annual business/profit plans.

Figure 1-1.

Achievement of Business Plans

This may be obvious, but I’ll say it anyway. Profits are not the only reason a company exists. A company exists to serve society and earn its respect. Today, more than ever, many companies are seriously asking themselves what they should do to be respected. To earn respect, a company’s success should include its ability to provide a stable and comfortable life for employees and to contribute to society with quality products and services. For these reasons as well, a company should be able to turn a profit.

Fostering and Using Improvement and Development Powers

Another very important reason to implement companywide improvement is to foster, utilize, and build the company’s improvement and development powers. Since the early 1980s, I have worked with many companies as a consultant and have closely observed their companywide activities. While some companies achieved their business plans almost perfectly year after year, others did not. At the end of the year, despite their rigorous efforts, many companies still fell short of their goals. Nevertheless, over time, some of them managed to transform themselves into much stronger organizations and even went on to achieve or surpass their targets.

The question here is what makes companies different? Of course, what and how improvement projects are chosen impacts whether or not a company achieves its business plans. These, however, are not the only reasons, nor are they the fundamental ones.

When companies discuss resources, they often refer to people, technologies, money, information, and time—all in the same breath. Yet each of these is different and each possesses different characteristics. For example, time is the same for your company as it is for your competition. Money, on the other hand, can be intentionally manipulated and moved around depending on a company’s situation at any given time.

What about people and technologies? (Technologies, by the way, are not limited to manufacturing industries; nonmanufacturing industries have technologies too.) Both people and technologies should be developed over time, a process that is possible only by building up one’s operational, organizational, and managerial powers year after year. Some companies purchase technology rather than developing it, but this is the exception rather than the rule.

To improve and transform, companies must continuously strengthen their people and their technologies. Simply borrowing or purchasing either resource will eventually lead to failure. Even if a company works hard one year, it cannot expect to improve these resources immediately. Developing people and technologies requires well-planned, continuous, and long-term effort. The difference between companies that achieve their business plans and those that don’t lies in their ability to accumulate powers over time—power to organize, work continuously, and develop. Without making a conscious effort to accumulate such powers, each year’s hard work just repeats itself and ends in disappointment. On the flip side, accumulating powers positions a company to succeed in related projects as well as new challenges. As a matter of fact, the more powers a company accumulates, the smoother its business goes.

How Are Powers Accumulated?

In Japan, we often suggest basing performance evaluations not only on results, but also on the process used to achieve results. It’s important, though, to go beyond emotional evaluations. Saying that someone worked hard or had a good attitude is not enough. The evaluation criteria must be clear and should include the following two questions:

1. What has the person learned by working hard? In other words, what new findings were made as a result of the improvement process?

2. Has the know-how been refined and formatted for future use? In other words, can the knowledge gained be transformed into viable information that others can use to guide them in similar cases?

When we work wholeheartedly, whether our results end in failure or success, our intrinsic and managerial knowledge expands. In this age of tough competition, hard work should include learning lessons from our efforts. This means we ought to extract the essence of individual experience and transform it into guiding rules that can be applied widely across the organization. If you really take a scientific approach to your work, you will accumulate know-how, transform the company, and give yourself a competitive edge.

How Do We Know We Are Making Progress?

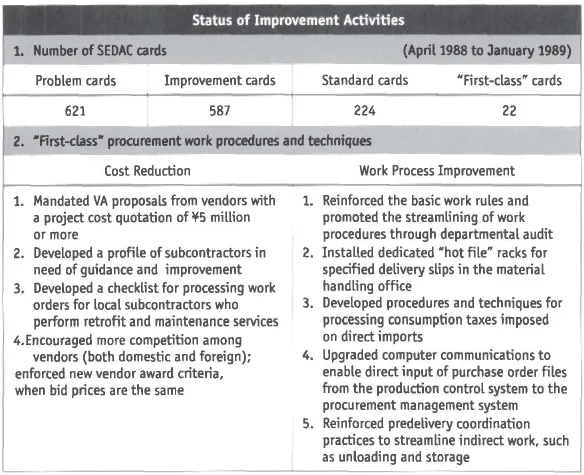

Item 2 in Table 1 - 1 shows examples of indicators that measure how well process objectives are achieved. For intrinsic technologies, it shows the number of technical standards, the number of research papers, and the number of patents. Management technologies, on the other hand, are another aspect that may not be as readily understood. Let’s look at some examples.

The Takasago Works of Mitsubishi Heavy Industries manufactures machinery for the electric power industry, including large-scale rotary machines, such as steam turbines for fossil fuel and nuclear power plants, gas turbines, hydro and wind power equipment, and refrigeration systems. The plant’s purchasing department took up an improvement initiative for material procurement practices. By effectively managing budget and material purchasing costs, and by strengthening value analysis (VA) practices, they were able to substantially reduce cost.

In the process of achieving this result, the purchasing department developed and standardized nine new work procedures and techniques as indicated in item 2 in Table 1-2. At the same time, department employees grew through their experience. By applying their newfound know-how, they are sure to do an even better job in the future.

Table 1-2.

Building Improvement Powers

(Purchasing Department, Takasago Works, Mitsubishi Heavy Industries)

For example, one of the nine new work procedures helped Takasago Works deal more effectively with vendors on its VA proposals. The company learned the key points of this procedure from a year’s worth of requiring vendors with a project cost of ¥5 million ($50,000)* or more to submit VA proposals. Then they standardized their know-how, which is now available for all department employees and should soon help them become more effective VA promoters.

The SEDAC cards in item 1 of Table 1-2 will be discussed further in Chapter 3, but need some explanation here. (SEDAC stands for Structure for Enhancing Daily Activities through Creativity.) The number of problem cards (621) represents the purchasing department’s list of problems, which need to be solved to achieve improvement objectives, overcome past obstacles, remedy undesirable situations, and remove the causes of problems.

The number of improvement cards (587) represents the number of ideas generated by department team members to resolve the above issues. The number of stan...