- 664 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Centrifugal Pump Clinic, Revised and Expanded

About this book

Maintaining the excellent coverage of centrifugal pumps begun in the First Edition -- called ``useful'' and ``indispensable'' by reviewers -- the Second Edition continues to serve as the most complete and up-to-date working guide yet written for plant and design engineers involved with centrifugal pumps.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Centrifugal Pump Clinic, Revised and Expanded by Igor J. Karassik in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Mechanics. We have over one million books available in our catalogue for you to explore.

Information

1 Application

Igor J. Karassik

Chief Consulting Engineer

Dresser Pump Company

Harrison, New Jersey

Question 1.1 How Far to Go in Preparing Pump Specifications

We are in the process of overhauling our purchasing practices for plant equipment. In the course of each year, we place orders for a large number of centrifugal pumps of many different types and sizes. Is it sound practice to prepare very complete and strictly detailed specifications, or is it better to outline the required conditions of service and let each pump manufacturer submit a quotation on the equipment he believes will best serve our requirements?

Answer

The question very carefully avoids giving a clue as to the present practices in this repect. Thus, it is impossible to guess whether the decision must be to liberalize and simplify the present system of dictating every detail of construction and choice of material or to tighten the reins on loose methods of purchasing whatever manufacturers’ representatives recommend as suitable or desirable.

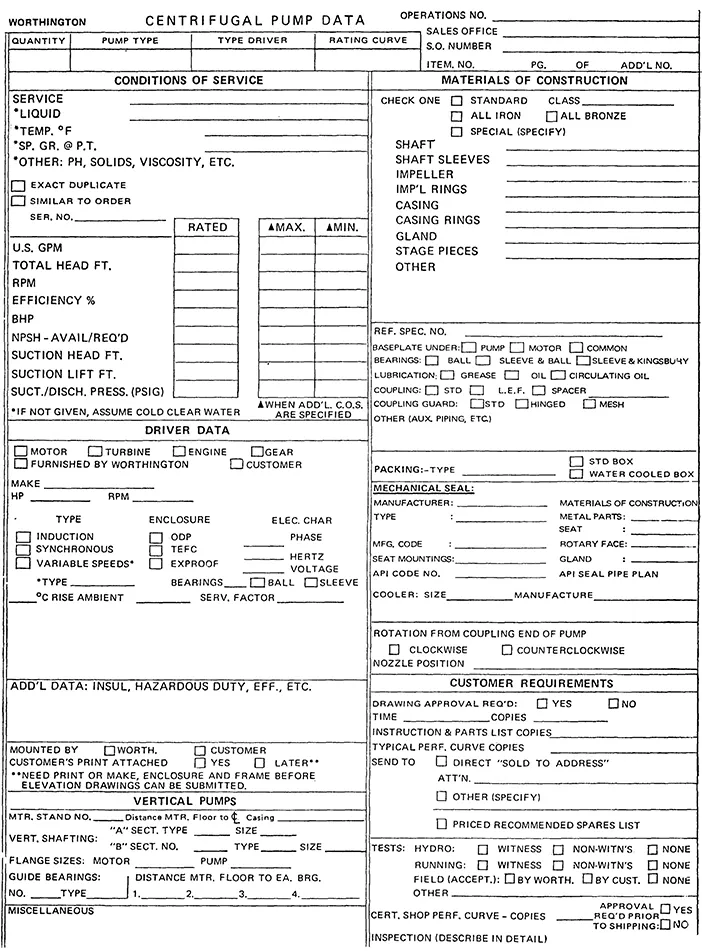

Whatever the present policies, it appears that changes are contemplated. But this is an extremely controversial question and rather difficult to answer quite objectively. I prefer, therefore, to permit my personal feelings on this subject to color my answer to some extent, and since I preface it with this warning, it should not cause anyone to take violent exception. The points covered here are basically those contained on the manufacturer’s typical data sheet (Fig. 1.1), the data entered there being the minimum amount of information required to select and build a pump.

Figure 1.1 Data sheet from the author’s company listing the information required to select and build a pump.

To begin with, I do not believe that centrifugal pump specifications can ever be too explicit or too detailed where the operating conditions are concerned. There are frequently circumstances that appear unessential to the purchaser that can affect the ultimate life of the equipment very materially. I shall cite one specific instance: The specifications of a generalservice vertical wet-pit pump that once came to my attention had been extremely detailed in all respects except in indicating the range of operating capacities. The inference had been that the pump would operate constantly at or about the design capacity. After the pump had been installed and very shortly after its initial operation, it was discovered that a serious shaft whip prevented satisfactory behavior of the stuffing-box packing. The pump shaft broke right under the impeller 2 months from initial operation. Investigation disclosed that 80% of the time the pump was operated in a range of flows from 25 to 10% of design conditions. This particular style of pump had a decided radial thrust in this range of capacities and was not suitable for operation except in the general range of 75 to 120% of rated flow. Had attention of the manufacturer been drawn to the actual type of operation, a pump suitable for this service could easily have been selected at very little higher cost to the user and the serious difficulties avoided.

Although we cannot treat in too great detail all the items that must be thoroughly investigated and made known to the prospective bidders, it may be advisable to list some of the essential information that should be stipulated in the specifications:

- What is the nature of the liquid to be pumped?

- Is it fresh or salt water; acid or alkali; oil, gasoline, or slurry; or other?

- Is it cold or hot, and if hot, at what temperature? What is the vapor pressure of the liquid?

- What is its specific gravity?

- Is it viscous or nonviscous?

- Is it clear and free from suspended foreign matter or dirty and gritty? If the latter, what are the size and nature of the solids, and are they abrasive? If the liquid is of a pulpy nature, what is the consistency expressed in percentage or in pounds per cubic foot of liquid? What is the suspended material?

- What is the chemical analysis, pH value, and so on? And what variations are expected in this analysis?

- What is the required capacity as well as the minimum and maximum amounts of liquid the pump will be called upon to deliver?

- What are the suction conditions? Is there a suction lift or a suction head? What variations are expected in these conditions?

- What are the discharge conditions?

- What is the static head? Is it constant or variable?

- What is the friction head?

- What is the maximum discharge pressure against which the pump must deliver the liquid?

- Is the service continuous or intermittent?

- Is the pump to be installed in a horizontal or vertical position? And if the latter,

- In a wet pit?

- Or in a dry pit?

- What type of power is available to drive the pump, and what are the characteristics of this power?

- What space, weight, or transportation limitations are involved?

- Where is the installation located? This should include reference to elevation above sea level, geographic location with its effect on recommended spare parts, and immediate surroundings that might affect accessibility.

- Are there special requirements or marked preferences with respect to the design, construction, or performance of the pump?

It is the last item that can easily become a very controversial issue. I believe that these special requirements or preferences should be listed but that the purchaser avoid too rigid an attitude toward a manufacturer who deviates from them in his quotation, provided that a sound explanation is given for the deviation. Remember that some of these preferences may be based on insufficient knowledge of the most modern practice or designs.

On the other hand, they may as likely originate from experience with pumps operating under the same conditions that the new pumps will have to meet. Much valuable information may be made available to the pump manufacturers which will enable him to furnish that type of equipment that will give the longest and most reliable service.

But I firmly believe that customers’ recommendations should be limited to their experience with pumps operating under similar conditions lest their preferences result in the purchase of very special equipment. Whenever the manufacturer’s standard construction can be used, it is preferable to specially build units, both from the point of view of initial cost and that of repair parts later.

To be sure, there are circumstances that may force the customer to write very “tight” specifications. This is the case, for instance, with municipal or federal agencies. The legal problems that arise with the purchase of any equipment by these agencies dictate the use of such specifications lest the agency be constrained to purchase unsatisfactory equipment merely because the bidder’s price is the lowest of all those submitted. But when such a situation does not exist, as in the case of private concerns who are not forced to buy the lowest bid, excess zeal in circumscribing the possible offerings into very narrow limits and in demanding special construction, special materials, and special tests when these are not needed does not lead to the selection of the most economical equipment.

Many customers, such as consulting engineering firms or large-volume buyers, find it advisable to develop “prefabricated” specifications for a variety of centrifugal pump services, such as boiler feed, heater drain, condensate, ash sluicing, and circulating water. This practice generally leads to a reduction in the cost of specification preparation, especially if customers frequently avail themselves of the help that can be given by pump manufacturers in reviewing these standard specifications in the light of the latest developments and experience.

In summary, I believe that centrifugal pump specifications should be as complete and detailed as possible with regard to “what must be performed by the pump” and as general as possible in restricting the manufacturer within the framework of unnecessary preferences or special treatment.

Question 1.2 Reducing Impeller Diameter to Correct Motor Overload

We have a centrifugal pump that is required to pump 20 GPM of water at 90 psi discharge pressure. The pump has a 7 in. diameter impeller and is driven by a 5 hp, 3500 RPM motor. When tested, it pumped 20 GPM at 100 psi pressure. The motor horsepower developed on this test was 6 hp. Evidently the motor is somewhat overloaded, and our discharge pressure is too high. What rules of proportion must be applied to reduce the impeller diameter to proper size?

Answer

A centrifugal pump is a velocity machine. A change in impeller diameter will change the peripheral speed of the impeller directly in proportion to this change. Furthermore, the velocities in the pump impeller and in the casing for similar points on the characteristic curve will vary directly in the same proportion. Therefore, the pump capacity, which is a direct function of the velocities, will vary directly as the impeller diameter ratio. The total head, which is a function of the square of the peripheral speed, will vary as the square of the diameter ratio. Finally, since the power consumption varies as the product of the head and of the capacity, the power will vary as the cube of the diameter ratio.

However, it must be remembered that, with a given impeller design, a reduction in impeller diameter will result in a change in the basic design of the impeller and thus may affect the pump characteristics. For this reason, the basic rule can be applied over only a limited range, depending on the type of the impeller. Furthermore, if the impeller diameter is reduced excessively, the pump efficiency will be somewhat affected, so that the power consumption will no longer follow the cube of the diameter ratio relationship.

In the particular case at hand and presuming that the suction lift or suction head is negligible (you give no value for this item), the efficiency of the pump will probably change very little if the impeller diameter is reduced to give 90 psi discharge pressure instead of 100 psi. The shape of the headcapacity curve at 20 GPM is probably very flat at the present operating point, so that the diameter ratio can be approximated from the square root of the two pressures. This results in an impeller diameter of about 6 5/8 in. After the impeller is cut, the vane tips should be filed very carefully to approximate the finish of the vanes as they now appear. Presuming that the impeller cutdown does not exceed reasonable limits for this pump (and this would not be likely), the power consumption at 20 GPM would vary directly with the pressure. (Note that in this case the power does not vary as the cube of the impeller diameter, since we d...

Table of contents

- Cover Page

- Mechanical Engineering

- Title Page

- Copyright

- Preface to the Second Edition

- Preface to the First Edition

- Contents

- 1 Application

- 2 Pump Construction

- 3 Installation

- 4 Operation

- 5 Maintenance

- 6 Field Troubles

- Index