- 294 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

Mining haul roads are a critical component of surface mining infrastructure and the performance of these roads has a direct impact on operational efficiency, costs and safety. A significant proportion of a mine's cost is associated with material haulage and well-designed and managed roads contribute directly to reductions in cycle times, fuel burn, tyre costs and overall cost per tonne hauled and critically, underpin a safe transport system.

The first comprehensive treatise on mining haul road design, construction, operation and management, Mining Haul Roads – Theory and Practice presents an authoritative compendium of worldwide experience and state-of-the-art practices developed and applied over the last 25 years by the three authors, over three continents and many of the world's leading surface mining operations. In this book, the authors:

-

- Introduce the four design components of an integrated design methodology for mining haul roads – geometric (including drainage), structural, functional and maintenance management

- Illustrate how mine planning constraints inform road design requirements

- Develop the analytical framework for each of the design components from their theoretical basis, and using typical mine-site applications, illustrate how site-specific design guidelines are developed, together with their practical implementation

- Summarise the key road safety and geometric design considerations specific to mining haul roads

- Specify the mechanistic structural design approach unique to ultra-heavy wheel loading associated with OTR mine trucks

- Describe the selection, application and management of the road wearing course material, together with its rehabilitation, including the use of palliatives

- Develop road and operating cost models for estimating total road-user costs, based on road rolling resistance measurement and modelling techniques

- Illustrate the approach of costing a mining road construction project based on the design methodologies previously introduced

- List and describe future trends in mine haulage system development, how mining haul road design will evolve to meet these new system challenges and how the increasing availability of data is used to manage road performance and ultimately provide 24x7 trafficability.

Mining Haul Roads – Theory and Practice is a complete practical reference for mining operations, contractors and mine planners alike, as well as civil engineering practitioners and consulting engineers. It will also be invaluable in other fields of transportation infrastructure provision and for those seeking to learn and apply the state-of-the-art in mining haul roads.

"This book is the most definitive treatise on mining haul roads ever written […] There has never been a text that addresses the many facets of mining haul roads on such a scope […]" From the Foreword by Jim Humphrey, Professional Engineer, Autonomous haulage systems developer and Distinguished Member of the Society of Mining, Metallurgy and Exploration.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Chapter 1

Introduction to mine haul roads

1.1 Importance of mine haul roads

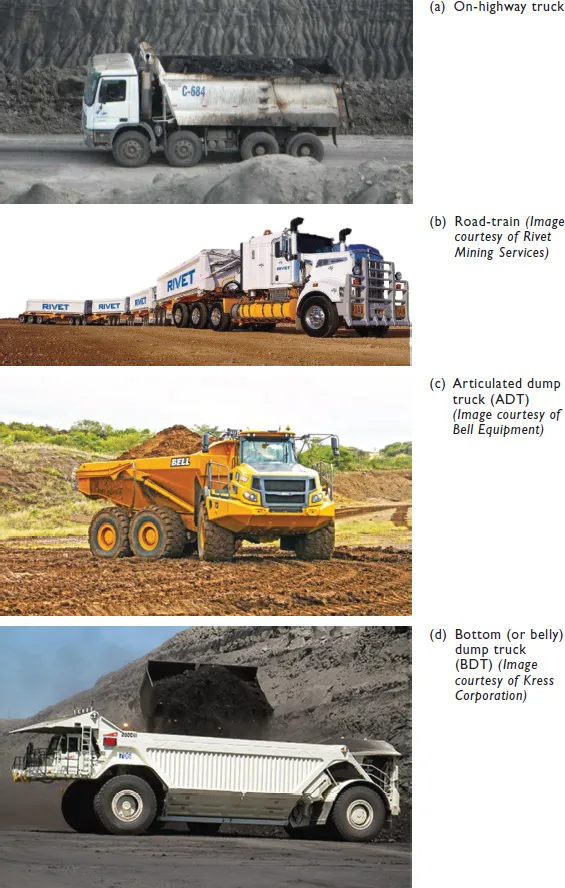

- Road legal:

- Sealed (paved) roads:

- Conventional truck and truck-semi-trailer combinations

- Single, double or triple trailer road trains, < 120 t capacity

- Unpaved roads, additionally:

- B-double, B-triple and Quad road trains (with powered trailer options), < 170 t capacity

- Sealed (paved) roads:

- Off road (unpaved) and in-pit:

- Small scale operations and civil construction – articulated dump trucks (ADTs), < 75 t capacity

- Custom road trains with > 200 t haulage capacity

- Rear-dump trucks (RDTs) and bottom-dump trucks (BDTs)

- over-design and specification, especially in the case of short-term, low-volume roads where the effect of rolling resistance, although minimised, does not contribute significantly to reducing total road-user costs across the mine’s network of roads due to the higher initial construction cost; or

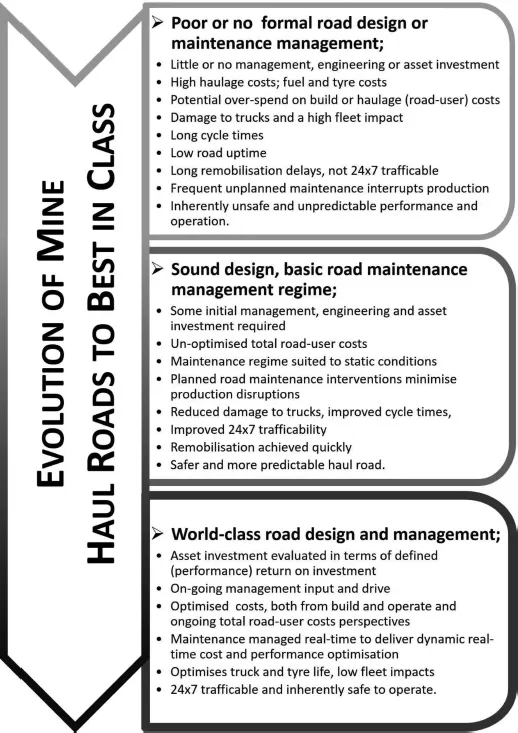

Figure 1.3 Evolution in mine road design and management.

Figure 1.3 Evolution in mine road design and management. - under-expenditure on road design and construction, leading to premature failure; excessive truck operating costs; loss of productivity and, in the case of longer-term, high-volume roads, high contributory costs from rolling resistance effects. Under-designed roads are often maintenance intensive, to the extent that even well-built roads appear to perform poorly, due to maintenance being postponed on these roads to accommodate the intensive conservation requirements of the under-designed roads.

- a safe, world-class road for all road-users;

- lowest vehicle operating costs, as a result of good haul road quality leading to faster cycle times and thus higher productivity and lower cost per ton;

- less stress on drive train, tyres, frame and suspension resulting in higher asset utilisation (less downtime) and component life; and

- optimum performance at minimum cost per ton hauled for the truck fleet and lower capital investment.

1.2 Characteristics of mine haul roads

Table of contents

- Cover

- Half Title

- Title

- Copyright

- Dedication

- Disclaimer

- Contents

- Foreword

- Abbreviations and notation

- Symbols

- 1 Introduction to mine haul roads

- 2 Concepts for geometrical design

- 3 Structural design of haul roads

- 4 Functional design

- 5 Road management and maintenance

- 6 Equipment performance and costing road construction

- 7 New technology and haulage equipment developments

- References

- Subject index