eBook - ePub

Learning by Doing with National Instruments Development Boards

- 160 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Learning by Doing with National Instruments Development Boards

About this book

Learning by Doing with National Instruments Development Boards starts with a brief introduction to LabVIEW programming, which is required to explore the National Instrument platform, an introduction that includes detailed installation and licensing setup. Further, it gives the features and configuration setup of NI SPEEDY-33, NI ELVIS and myRIO boards. The focus of the book is on worked-out case studies for students working in different areas of electronics such as basic digital design, biomedical instrumentation, sensors and measurement. Data acquisition using SPEEDY-33, NI –ELVIS and myRIO kits is also odiscussed. The book also examines the myRIO platform.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

CHAPTER ONE

A Glimpse of LabVIEW

1.1 What is Virtual Instrumentation

Virtual instrumentation (VI) is a multifaceted field to combine software and hardware technologies so as to create instruments both sophisticated and flexible for monitoring as well as control applications. There are quite a few descriptions of a Virtual Instrument.

1. A Virtual Instrument as described by Santori is “an instrument whose capabilities and general functions are decided by the software” [1].

2. Goldberg says “A Virtual Instrument is made up of various general-purpose computers, some software, a few dedicated subunits and a little technology” [2,3].

3. These descriptions capture the fundamental ideas of VI and virtual concepts overall which are affordable: “any computer can replicate another, if it is loaded with software to simulate another computer” [4].

1.2 History of VI

The history of VI is differentiated by continuous enhancement of scalability and flexibility of the measurement equipment. Beginning with the first vendor-defined manual-controlled electrical instruments, the field of instrumentation has progressed toward current sophisticated measuring equipment which is user-defined and controlled by a computer.

It has progressed through the following stages:

1. Analog measurements

2. Data acquisition and data processing

3. Digital processing

4. Distributed VI

The first stage represents analog devices such as EEG or oscilloscope recording systems which were completely sealed and dedicated systems inclusive of sensors, power suppliers, displays and translators [5]. Manual settings were required to display results on several counters, CRT displays, gauges or paper. Additionally, the user had to copy data onto a data sheet or a notebook physically, since copying data was not possible. Subsequently, everything had to be done physically since performing automated tests or complex procedures was rather impossible.

The second stage was launched in the 1950s since the industrial control field insisted on the same, wherein rudiment control systems with integrators, rate detectors and relays were incorporated in the instruments. This led to the formation of proportional-integral-derivative (PID) control systems that permitted flexibility of automation of quite a few phases of measuring processes and test procedures [2,3]. Digital processing of data was possible since signals were digitalized in the instruments.

In stage three, measuring instruments were computer based, which included interfaces that allowed communication connecting the computer and the instrument. In the 1960s, Hewlett-Packard (HP), previously known as HPIB, started the relationship which was started by the General-Purpose Interface Bus (GPIB) for the purpose of control of instruments by the HP computers. Originally computers were made use of as off-line instruments which were further used to process data after recording on a disk [6]. Computers became faster for real-time measurements as the capabilities and the speed of the computers increased. Then manufacturers incorporated the necessary hardware and software required by the instruments for the specific applications. The most important advantages of PCs are standardization and availability due to the low price in the market. In 1986 National Instruments launched LabVIEW 1.0 [1], which had Graphical User Interfaces (GUI) making it user friendly and affordable.

The fourth stage came into being with the development of global and local networks of computers. With the development of computerized instruments, physical distribution of VI components was made possible to offer medical information and services from afar with the help of network and telecommunication technologies. Infrastructure for allocated VI includes cellular networks, private networks and the internet, where the interface amidst the components could be balanced for performance and price [2,3].

1.3 LabVIEW and VI

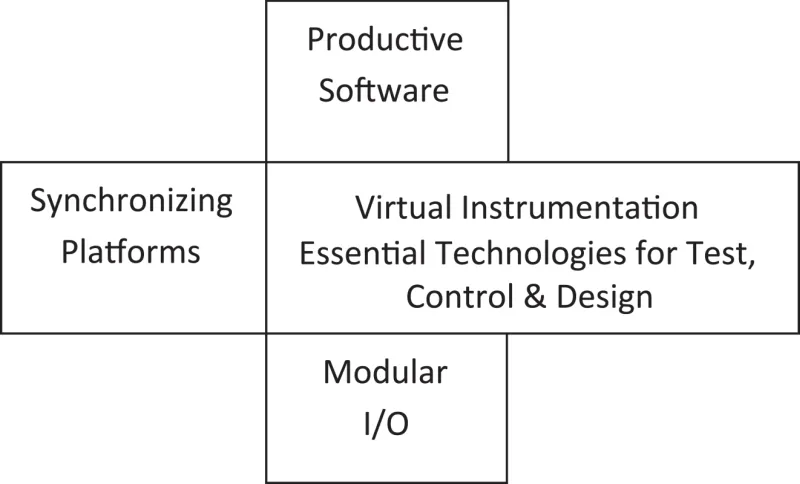

Computers are combined by VI with hardware and software. VI are used by engineers to carry out the power of PC technology to design, control and test applications and flexible software to make accurate digital and analog measurements. Scientists and engineers can produce user-defined systems to meet the specific application needs. Manufacturers with automated processes, for instance manufacturing or chemical plants, use VI with the aim of improving reliability, system productivity, stability, optimization and safety. VI is a computer software that any user could employ to build up a computerized measurement and test system in order to control from a desktop, an external hardware device and also for displaying measurement or test data accumulated by any external device on panels like a computer screen. It is also used to computerize systems for organizing processes based on collected and processed data. The control function of the front panel is duplicated on the computer interface. Applications range from simple experiments in the laboratory to large automations. VI as shown in Figure 1.1 uses synchronizing platforms, modular I/O and productive software.

The first VI element uses Synchronizing Platforms to ensure that VI takes advantage of the data transfer technologies and the latest computer capabilities. The element delivers VI on a long-standing technology base which ranges with the huge investments made in buses, processors and much more. The second VI component is a Modular I/O, designed to be combined rapidly in any quantity or order to make sure that VI can either control or monitor any developing feature. Scientists and engineers and can rapidly access functions by using ingenious software drivers for Modular I/O during synchronized operation. Finally, in order to speed up development, NI LabVIEW, a premier VI graphical developed environment, uses graphical or symbolic representations. The software uses symbols to represent various functions. VI is termed as a computer having low cost driver software and hardware and user friendly application software which performs the functions of instruments together. VI is also known as simulated physical instruments. With VI, scientists and engineers lower their design costs, design higher quality products and decrease development time.

VI is essential since it is flexible. It carries on instrumentation with the swift adaptability needed for today’s delivery, concept, development, process and product design. With these instruments, scientists and engineers can keep up with upcoming demands with the latest technology. For example, a mobile phone now has Internet Browsing, Bluetooth Networking, MP3 Player and Camera, although it was originally used to call and send SMS.

VI consists of hardware and software and is required to fulfill the control or measurement task. Further, scientists and engineers can customize sharing, storage, presentation functionality, analysis and acquisition using powerful and productive software. A multiple purpose VI can be manufactured by using a data acquisition card or board of which the benefits include size, ease of programming, cost and flexibility. VI software has many layers such as application software, data and test management software, and control and measurement services software. The application software is the basic development environment used to build applications including software like LabVIEW, VI Logger, Signal Express, Measurement Studio and LabWindows/CVI. Above this layer is the data and test management software which incorporates the functionality of the previous layer and offers data management. Cont...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Foreword

- Preface

- Authors

- 1 A Glimpse of LabVIEW

- 2 Board features and configuration setup

- 3 Exploring SPEEDY-33

- 4 Exploring NI ELVIS

- 5 Exploring myRIO

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Learning by Doing with National Instruments Development Boards by Jivan Shrikrishna Parab,Ingrid Anne Nazareth,Rajendra S. Gad,Gourish Naik in PDF and/or ePUB format, as well as other popular books in Computer Science & Programming Languages. We have over one million books available in our catalogue for you to explore.