Fibres to Smart Textiles

Advances in Manufacturing, Technologies, and Applications

- 390 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Fibres to Smart Textiles

Advances in Manufacturing, Technologies, and Applications

About this book

Fibres to Smart Textiles: Advances in Manufacturing, Technologies, and Applications offers comprehensive coverage of the fundamentals and advances in the textile and clothing manufacturing sectors. It describes the basics of fibres, yarns, and fabrics and their end use in the latest developments and applications in the field and addresses environmental impacts from textile processes and how to minimize them.

This book serves as a single comprehensive source discussing textile fibres, yarn formation, filament formation techniques, woven fabric formation, knitting technologies, nonwoven manufacturing technologies, braiding technologies, and dyeing, printing, and finishing processes. Testing of textile materials, environmental impacts of textile processes and use of CAD and CAM in designing textile products are also included. The book also discusses applications including textile composites and biocomposites, technical textiles, smart textiles, and nanotextiles.

With chapters authored by textile experts, this practical book offers guidance to professionals in textile and clothing manufacturing and shows how to avoid potential pitfalls in product development.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

1 | Textile Fibres and Recent Developments |

CONTENTS

1.1INTRODUCTION

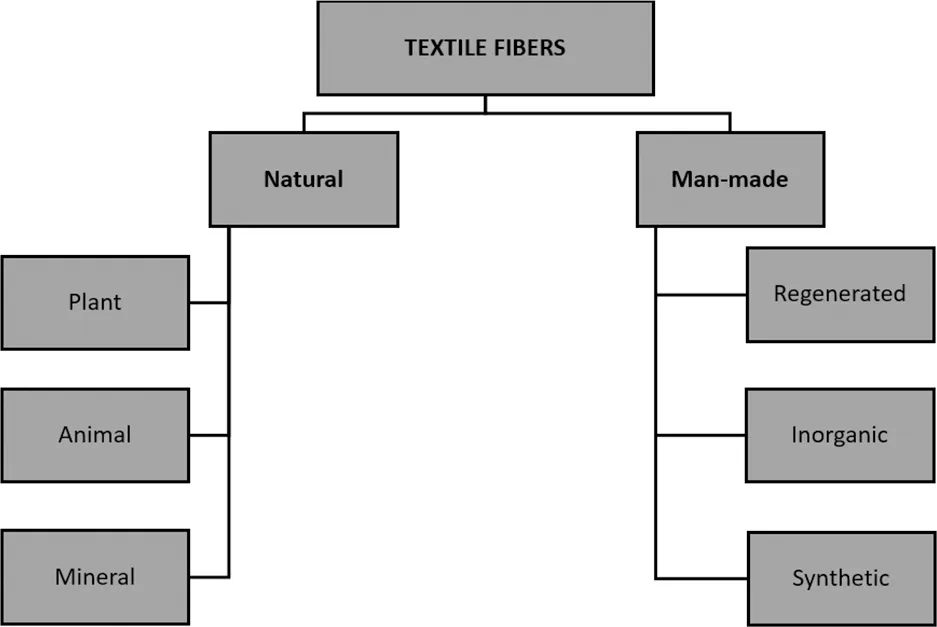

1.2FIBRE CLASSES

1.2.1CLASSIFICATION BASED ON THE LENGTH OF FIBRES

- Staple fibre refers to fibres of short length. Most of the natural fibres such as cotton, flax, hemp, wool, except silk, are staple fibres.

- Filament fibre refers to relatively very long or continuous length fibres that can range from hundred metres to kilometres.

1.2.2CLASSIFICATION BASED ON THE ORIGIN AND SOURCE OF FIBRES

1.3NATURAL FIBRES

1.3.1PLANT FIBRES

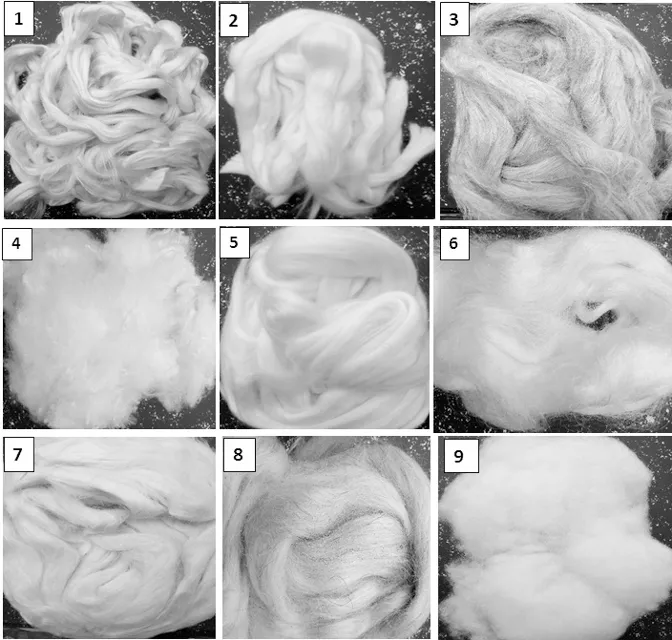

1.3.1.1Cotton

Table of contents

- Cover

- Half Title

- Series Page

- Title Page

- Copyright Page

- Dedication Page

- Table of Contents

- Series Preface

- Preface

- Editors

- Contributors

- Chapter 1 Textile Fibres and Recent Developments

- Chapter 2 Filament Formation and Recent Developments

- Chapter 3 Yarn Formation and Recent Developments

- Chapter 4 Fabric Formation and Recent Developments

- Chapter 5 Knitting and Recent Developments

- Chapter 6 Non-Woven Fabrics: Technology, Applications and Recent Developments

- Chapter 7 Braiding and Recent Developments

- Chapter 8 Preparatory Chemical Processes and Recent Developments

- Chapter 9 Dyeing and Recent Developments

- Chapter 10 Printing and Recent Developments

- Chapter 11 Finishing Processes and Recent Developments

- Chapter 12 Testing of Fibres, Yarns and Fabrics and Their Recent Developments

- Chapter 13 Recent Developments to Reduce Environmental Impacts of Textile and Apparel

- Chapter 14 Use of CAD and CAM and Its Recent Developments in Textiles

- Chapter 15 Recent Developments in Textile-Reinforced Composites and Biocomposites

- Chapter 16 Technical Textiles and Recent Developments

- Chapter 17 Smart Textiles and Recent Developments

- Chapter 18 Nanotextiles and Recent Developments

- Index