![]()

Chapter 1

Supportive Organisation Structure – Element 1

There has been much written about organisational structures and span of control; however, if you are seeking to develop an Operational Excellence organisation that is based on developing the capability of all your people so they can be effective problem solvers, use Visual Management to identify problems at the earliest possible time, and practice Prevention at Source to stop problems from happening, then we need to understand the key aspects of Operational Excellence.

The first is Dr. W. Edwards Deming’s three key points regarding quality, which he taught the Japanese in their formative years of developing the Toyota Production System that led to the introduction of single-piece flow.

1. Focus on the process, not just the activity – look at the performance of the whole line to ensure the workload is balanced rather just the activity of one person.

2. Apply ‘Prevention at Source’ for the process – ensure problems and issues are identified at the earliest possible time rather than at the end of the line after all the value has been added.

3. Recognise the ‘Tyranny of Time’ when addressing problems – the longer the time gap between when a quality problem occurs and you finding out about it, the less chance you will have of easily finding the root cause.

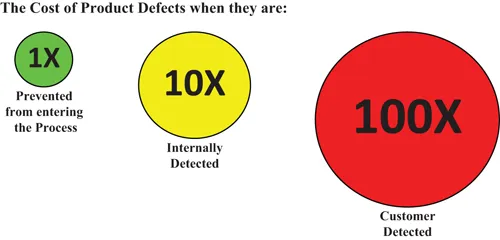

The cost implications of not finding quality problems at the earliest possible time can have a significant negative impact on the bottom line as outlined in Figure 1.1.

Figure 1.1 The cost of product defects when they are detected.

As such, your organisation structure should be designed to ensure all people with direct reports can play a leading role in assisting their direct reports to find and respond to quality problems at the earliest possible time, rather than the more traditional focus of just allocating and managing tasks.

The second is the importance of Workplace Ownership and its impact on plant and equipment reliability, more specifically stopping breakdowns and achieving best practice Overall Equipment Effectiveness (OEE) performance based on your business requirements.

The Causes of Equipment Failure and the 5 Whys

m Before discussing the causes of equipment failure, we would like to refresh your memory of the improvement tool called Why-Why Analysis or the 5 Whys by Talichi Ohno.

Why-Why Analysis is a simple technique of asking why 5 times recognising that after 5 whys you are most likely to be at the root cause or primary cause for the problem.

We will use a simple example to demonstrate what we mean. A person lives in a house that has a long drive way going down to the garage under the house. One morning they get in their car to go to work and back the car out of the garage and up the long driveway only to find the car is steering funny. They could ignore this and keep driving to work (not very smart) or they could stop at the top of the driveway and ask the question:

Why (1) is the car driving funny?

They get out and investigate and find they have a flat front tyre. At this point they can curse and change the wheel and carry on OR ask the question:

Why (2) is the tyre flat?

After examining the flat tyre they discover a large nail in it. At this point they can curse a bit more and put on the spare wheel OR ask the question:

Why (3) did the tyre get a nail it?

Knowing the car didn’t appear to have a flat tyre last night when it was driven home they walk down the driveway looking for nails and find several similar nails on the garage floor. At this point they could sweep up the nails, put on the spare wheel and carry on, OR ask the question:

Why (4) were there nails on the garage floor?

Knowing they didn’t put them there themself they could ask the other members of the family and discover that their children had been playing with the nails and left them on the floor. At this point they could chastise their children, sweep up the nails, put on the spare wheel and carry on, OR ask the question:

Why (5) were the children able to get hold of the nails?

They then remember they were using the nails on the weekend and left them out in easy access for the children instead of putting them away when they rushed off to watch the football on TV.

So what is the root cause? Having children! No, it’s leaving the nails out so the children could get to them.

Unless the nails are properly put away, it is likely they will end up on the garage floor again.

In the workplace we rarely get to the root cause because we are too busy changing the flat tyres! However, unless we get to the root cause we will always have problems reappearing.

What Is the Pathway of Mechanical Equipment Failure?

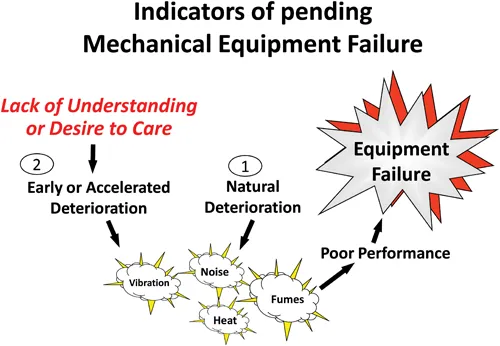

If we work backwards from equipment failure (a bit like the 5 Why Analysis approach) and ask what indications we had that the equipment might fail, we first find poor performance often occurs before failure. Before this, we often have vibration, noise, heat and/or fumes coming from our equipment. This can be caused by one of two reasons (Figure 1.2):

Figure 1.2 Indicators of pending mechanical equipment failure.

1. Natural deterioration, or

2. Early or accelerated deterioration

Natural deterioration: Is when an item or component reaches its design life. Everything has a life due to normal operation. Ideally all the components should achieve their design life; however, what we find in many situations is that components deteriorate earlier than their design life.

Early or accelerated deterioration: This is where a component of the equipment wears out quicker than is expected. In other words, it wears out quicker than its design life. Its life is shortened because its natural deterioration is accelerated. This is the area of focus that can save significant costs if we are able to reduce or eliminate early or accelerated deterioration. To understand more about this, let us look at failure mechanisms.

Failure Mechanisms of the Parts that Make Up Our Plant and Equipment

Failure Mechanisms

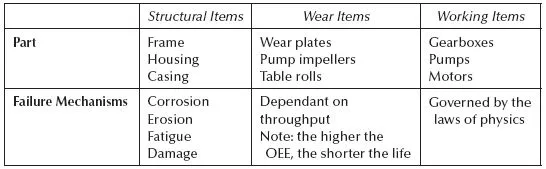

To simplify the discussion, let us look at the failure mechanisms of the mechanical parts that make up our plant and equipment. A simple example we use in our workshops is the laptop computer or data projector which is sitting in front of everyone. The parts of a laptop computer or data projector, like most pieces of equipment in our plants, can be broken down into three broad categories:

1. Structural Items such as the casing or housing

2. Wear Items such as the keyboard

3. Working Items which are all the moving parts like the switches, fan, etc. that make the laptop or data projector function

In Table 1.1 we have identified the different failure mechanisms for the three different categories of items.

Table 1.1 Failure Mechanisms

Our main interest is with the working items. These by far make up the majority of items which need maintenance attention and often contribute most to our overall Maintenance Spend. So, let us understand the impact of the laws of physics on our working parts.

Example of the Impact of the Laws of Physics on the Failure Mechanisms of Working Items

■ Movement between contacting surfaces creates friction and wear

■ Proper lubrication provides an interface between moving surfaces

■ A key role of lubrication is to be a sacrificial wear element.

Hence early or accelerated deterioration occurs when:

■ Lubrication is not present

■ Lubrication is incorrect for the application

■ Lubrication between the surfaces is forced out due to overload

■ Lubrication wears out

■ Lubrication becomes contaminated

If we were to rub our hands together for the rest of the day we will get very sore hands because the layers of skin rub off. To stop this from happening we would need to apply some form of lubrication to act as an interface between our hands.

Proper lubrication provides an interface between moving surfaces and a key role of lubrication is to be a sacrificial wear element. That is, the lubrication wears out as the moving surfaces interface with it. This is why we are recommended to replace the oil in our cars at say every 10,000 km. This is not because the oil is dirty even though it may look dirty; it is continuously filtered and clean. The reason for replacement is that the oil has worn out.

Hence, as an example, ‘early or accelerated deterioration’ occurs when lubrication is not present, lubrication is incorrect for the application, lubrication between surfaces is forced out due to overload, lubrication wears out or lubrication becomes contaminated.

Often when walking through business plants we see operators ‘blow down’ the equipment with compressed air, or hose it down with high-pressure water so as to get rid of contamination, such as spillage. Unfortunately, what most operators don’t understand is that they could be forcing contamination into the sensitive parts of the equipment, such as bearing seals or electrical cabinets, without even realising it or caring about it. In other words, lack of understanding or desire to care is the primary cause of early or accelerated deterioration.

We have found that the lack of understanding or desire to care can come from many sources including:

Designing

Procuring and Storing

Installing

Operating

Maintaining

We have also found that, apart from new plants where design problems often abound, the biggest issue in existing plants is often the...