- 546 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Longwall Mining, 3rd Edition

About this book

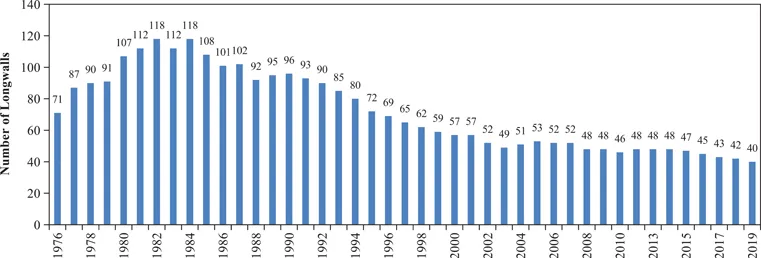

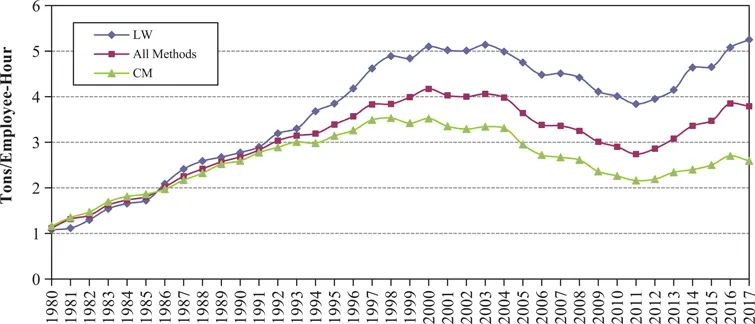

In the past 13 years since the publication of Longwall Mining, 2nd edition in 2006, although there have been no major changes in longwall mining technology and operations, many incremental developments in the whole system as well as various subsystems of the existing longwall mining operational technologies as detailed in the 2nd edition have been added to this edition.

Major developments are automation, and health and safety technology, as well as equipment reliability, thereby greatly increasing productivity and cutting cost. In particular, the longwall system can now run automatically cut by cut forever without operators' intervention provided that the geology allows it. Other health and safety features such as LASC, personal proximity detection, color lighting, automatic shield water sprays and remote shearer control are fully operational. There are more than 7000 sensors installed in current longwall mining systems. The big data obtained and fast communication technology have been fully utilized to improve and solve operational problems in real time. Those features are fully documented in the new edition. In pursuit of high productivity and cutting cost, life cycle management that increases equipment reliability has been implemented by OEM. Automation improvement such as tail-end automatic chain tensioner greatly extends AFC chain's service life. Other incremental improvements including dust and methane controls, entry development, panel design and face move are addressed. Additional operational issues such as extension of panel width and compatibility test are also discussed. Since the last plow longwall mine was closed in 2018, the chapter on plow longwalling has been dropped and in its place Automation of Longwall Components and System is added. Also, a new chapter Longwall Top Coal Caving Mining (LTCC) is added due to its successful application in Australia since 2005.

Longwall Mining, 3rd edition will be of interest to professionals and academics in the field of mining engineering specifically, serving both as a reference work and an (under)graduate textbook, but will also interest civil, geomechanical and geological engineers and rock mechanics professionals, as well as coal operators, mining consultants, researchers, equipment manufacturers, and government regulators.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Chapter 1

US longwall mining

1.1 Introduction

1.2 Requirements and constraints for high production longwalls

- Favorable geological conditions – Coal seams are flat, fairly uniform and shallower, mostly less than 2100 ft (640 m), and the roof strata are generally easy to cave.

- Excellent mining plan and equipment layout – US longwalls employ multi-entry gateroad development using continuous miners, which allows rapid gateroad development, and the layout creates minimum abutment pressure interaction between adjacent panels. Specific improvements to equipment and layout unique to US longwalls are addressed in Section 7.2, “Layout of Longwall Face Equipment Using the Shearer.”

- State-of-the-art equipment – All equipment are heavy duty and highly reliable. Individual subsystem reliability is greater than 90% without, increasing to close to 100%, with industry/OEM partnership services programs. The whole system reliability is more than 85% without a partnership program.

- Highly efficient method of face move – For a 1200 ft (366 m) wide panel, a complete face move can be done in five to seven days (Note, normally the shearer and AFC and stage loader are pre-installed in a new face.). A complete face move is up to two weeks.

- Excellent management and skilled work force in a highly competitive world market.

- Production and safety incentive programs.

1.3 Panel layout

- The process uses a retreating longwall mining method with natural roof caving in the gob.

- All longwalls are single slice or single seam and operate in flat or nearly flat coal seams.

- Panel development uses the room-and-pillar method in which multiple entries (two to four entries, mostly three entries) are developed simultaneously in-seam in a rectan...

Table of contents

- Cover

- Half Title

- Title

- Copyright

- Contents

- Preface

- Acknowledgments

- 1 US longwall mining

- 2 Longwall mine design

- 3 Strata mechanics

- 4 Panel development

- 5 Shield support – general

- 6 Shield support – design/selection

- 7 Coal extraction by the shearer

- 8 Coal transportation

- 9 Automation of longwall components and systems

- 10 Application issues of longwall mining

- 11 Ventilation and methane, dust, and noise controls

- 12 Longwall face move

- 13 Longwall power distribution and system control

- 14 Surface subsidence

- 15 Longwall top coal caving mining

- References

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app