- 288 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Pipejacking & Microtunnelling

About this book

Covers development of trenchless technology; pipejacking and microtunnelling methods equipment: shields and tunnel boring machines; pipejacking: line, drive pit, top side; equipment: microtunnelling; design concepts.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Development of trenchless technology

1.1 Recent growth of trenchless technology

Trenchless technology broadly brings under one banner a variety of non-disruptive techniques for installing, replacing or renovating underground pipes and cables without open-cut excavation. The term was introduced as recently as the early 1980s. Through the efforts of the International Society for Trenchless Technology (ISTT) and information disseminated at No-Dig Conferences, trenchless technology has become accepted as a specific construction term. Pipejacking, as both a principle and a technique, is a trenchless method of pipelaying that existed long before this term.

The pipelaying industry is now having to move away from its traditional ways of working. Not only is it having to adapt to changes in client needs, but also to changing attitudes of both publics and governments (local and central) as they respond to the wider social, political and economic changes around them.

In industrialised countries, pipelaying is no longer primarily concerned with installing new networks, as most households are already connected to sewers, gas, water, electricity and telecommunication services. Work is now more usually focused in established urban areas where ageing utility networks, often well past their design life, are in need of replacement or rehabilitation. By definition, these are the areas with the densest population and the greatest congestion. The whole question of how pipes are installed or renovated is understandably being thrown into sharper relief.

Public and government resistance is hardening against the disruption of traffic, commerce and community well-being caused by open-cut methods of working. People are now realising that traditional open trenching inflicts real costs on communities, as well as inconvenience. The disruption factor of pipelaying is under scrutiny and from now on it will be an element of installation programmes which must be accounted for. To meet the challenge of changing needs and stricter requirements, new and often more sophisticated trenchless techniques of pipelaying have been introduced, and existing ones refined. As these techniques are more widely accepted as viable alternatives to open-cut working, trenchless systems are competing with traditional installation methods—not just on technical grounds, but also for good economic reasons. With greater production and increased utilisation rates, prices for trenchless solutions have become directly competitive.

1.1.1 Categories of trenchless technology

The many types of trenchless technology now available are generally categorised into three main groups according to their application, as shown in Table 1.1.

Table 1.1 Categories of trenchless technology

The following charts show the types of trenchless technology available and their applications. Table 1.2 summarises installation methods for all types of pipe, for gravity sewers and pressure pipe. Table 1.3 lists the methods of installing sewers and pressure pipes for cased crossings. Trenchless methods for on-line replacement and for structural renovation are summarised in Tables 1.4 and 1.5 respectively, gravity sewer and pressure pipe applications again being shown separately.

Table 1.2 Trenchless methods used for new installation

Table 1.3 Trenchless methods for cased crossing

Table 1.4 Trenchless methods for on-line replacement

Table 1.5 Trenchless methods for structural renovation

1.2 Defining pipejacking and microtunnelling

1.2.1 Pipejacking

Pipejacking describes a specific trenchless technique for installing pipes. Pipejacking is also used as a more general term for a principle which is fundamental to a number of trenchless techniques. It is important to differentiate between the principle and the technique.

The principle of using hydraulic rams to push up pipe sections to line the hole formed by a cutting head, or shield, applies to auger boring and microtunnelling as well as to the pipejacking method itself. The principle of jacking pipes is the same whether one is installing a 100 mm auger bore casing or driving a concrete underpass for vehicles. Figures 1.1 to 1.3 show how the pipejacking principle is applied to auger boring, microtunnelling, and pipejacking. Figure 1.4 is an example of a jacked underpass. The size range varies from 100 mm for the auger bore to 20 m by 7 m for the underpass.

Pipejacking is the name given to the technique of installing pipe of man-entry size by pushing sections from the drive shaft into the hole formed by the cutting shield to provide a continuous tunnel lining. These sections do not have to be circular and can be of almost any dimensions. The cutting shield external dimension can be sized to conform closely to the external diameter of the pipe being pushed; this eliminates or reduces to a minimum the annular space created. Diameters considered man-entry vary slightly from one country to another, but 900 mm has become a widely accepted lower limit.

Pipejacking was initially developed for installing casings for crossings and is still widely used for this purpose. As techniques and skills improved, it evolved into a method capable of installing pipes direct without a casing, particularly gravity sewers. By so doing, pipejacking has moved into the traditional small diameter tunnelling market. Here it competes with alternative methods of installation, in particular with segment linings, which are erected immediately behind the shield as it advances. The shields and tunnel boring machines (TBMs) used at the leading end of the tunnel are virtually the same for jacking and segment tunnelling. The only difference is in the way the tunnel is lined.

Figure 1.1 Auger boring rig

Figure 1.2 Microtunnelling

Figure 1.3 Pipejacking

Figure 1.4 Jacked underpass (by courtesy of Cementation Projects Ltd)

1.2.2 Microtunnelling

Microtunnelling is the term for pipejacking in smaller diameters, as its name implies. Microtunnelling equipment is used to install pipes with an internal diameter less than 900 mm, i.e. diameters generally accepted as too small for safe man-entry working. However, the upper limit of 900 mm is not sacrosanct. The Japanese consider an internal diameter of 800 mm large enough for man-entry working, whereas in Europe there is a move towards raising the microtunnelling limit to 1000 mm, particularly for longer drives. Whatever the precise upper limit, microtunnelling is a method of installing pipes to a predetermined line and level by remote control. Excavation, spoil removal and shield steering are all remotely controlled.

The difference between pipejacking and microtunnelling is therefore chiefly a matter of size and not a question of whether the system is or is not remotely controlled. As far as categorising equipment is concerned, the division is meaningless. A manufacturer may have a range of remotely controlled machines of the same design ranging from 500 mm to 1500 mm or greater. Remote-control methods are increasingly being selected for installing pipes of 2000 mm and less.

The predominant application for microtunnelling is the direct installation of gravity sewer pipes, but other forms of pipe and duct are also direct-installed in this way, although still a relatively small proportion. In some circumstances microtunnelling can be an effective means of installing duct at crossings.

A spin-off from the development of remotely controlled machines for new installation has been their use in the on-line replacement of sewers. Microtunnelling equipment has been adapted to break up and excavate an existing sewer and to lay a replacement pipe all in one operation.

1.3 A historical perspective

1.3.1 Pipejacking

The pipejacking principle was thought to have first been used in Roman times. Excavations in the Middle East suggest that a wooden pipe was jacked underground with a series of levers and tapped into the side of a Roman aqueduct to gain illicit access to water. The motive was different, but the objective was the same: to lay a pipe without disturbing the surface.

Early pipejacking in the USA. The first recorded description of the pipejacking method seems to have been in 1892 [1]. The first records of pipejacking jobs were for installations done in the USA between 1896 and 1900 for the Northern Pacific Railroad Company [2] [3]. Gradually it became standard practice for a number of railroad companies to jack cast iron pipes under rail tracks. Further records show pipes were jacked under the Great Western Railway at Ingalton, Illinois, in 1911 and for Southern Pacific in California in 1915.

Augustus Griffin is credited with the early popularisation of the jacking method (see Figure 1.5). It was while working on irrigation schemes in California, between 1906 and 1918, that Griffin developed techniques for jacking cast iron pipe culverts under rail tracks. Figures 1.6 and 1.7 are taken from one of Griffin’s articles [4].

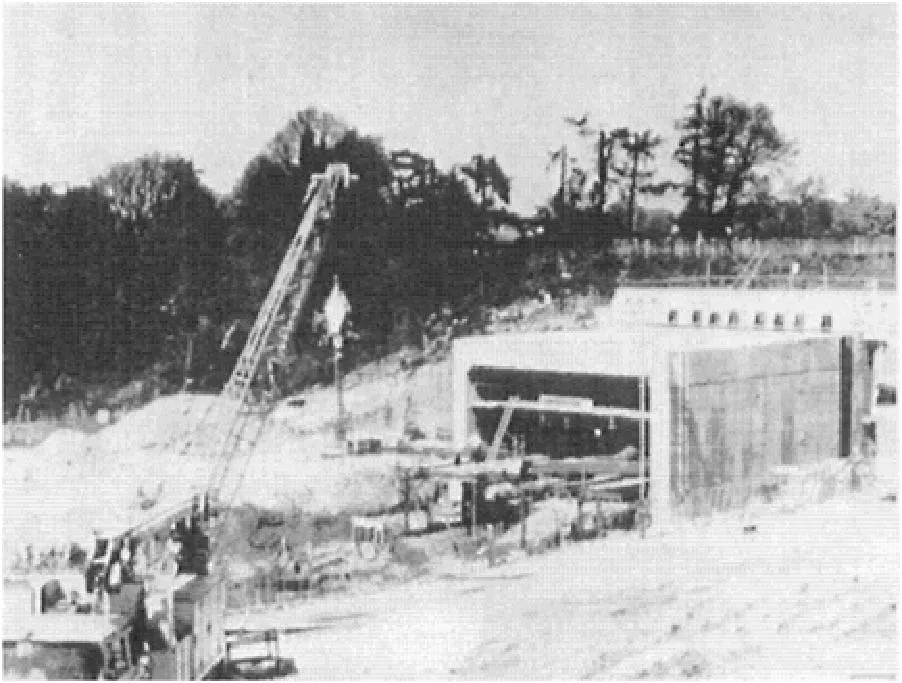

Corrugated steel pipes started to replace cast iron in the early 1920s. Pipejacking accounted for some 830 jobs between 1922 and 1947, totalling 16,800 m (56,000 ft) with diameters from 700 mm to 2400 mm (28–96 in). In his paper published in 1948, Jacob Feld [5] lists in a table some of these installations, which in some cases achieved drives of 60 m (200 ft) or more. Figure 1.8 shows an early crossing under an embankment.

By the late 1920s, concrete pipes were being used. A paper published in 1942 for the American Concrete Pipe Association [6] refers to some jobs using concrete pipes in the 20-year period from 1927. Pipe sizes ranged from 750 mm to 2400 mm (30–96 in). In the 1930s, Northern Pacific standardised the use of concrete jacking pipes with internal diameters from 108 mm to 1800 mm (42–72 in). Of particular note was the jacking in 1945 of a concrete pipe, 2400 mm (96 in), for a pedestrian subway under the Richmond, Fredricksburg and Potomac railroad at the Potomac yards, Alexandria. Cover from the base of the railway was a scant 750 mm (2 ft 6 in).

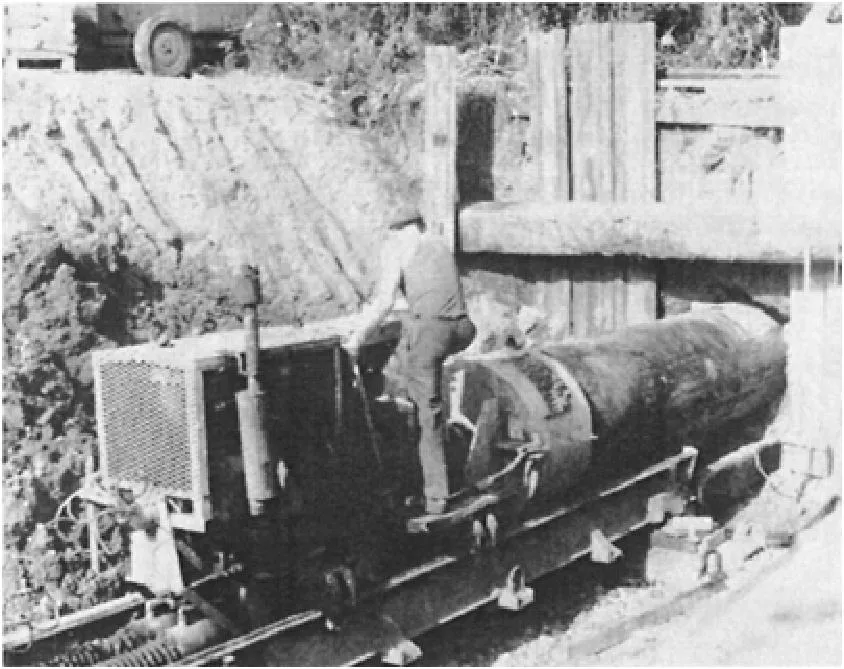

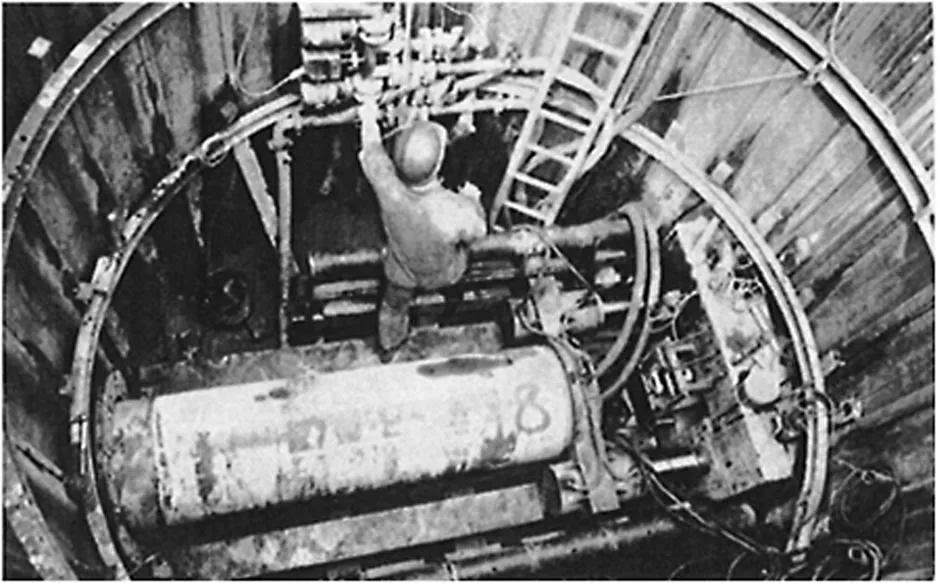

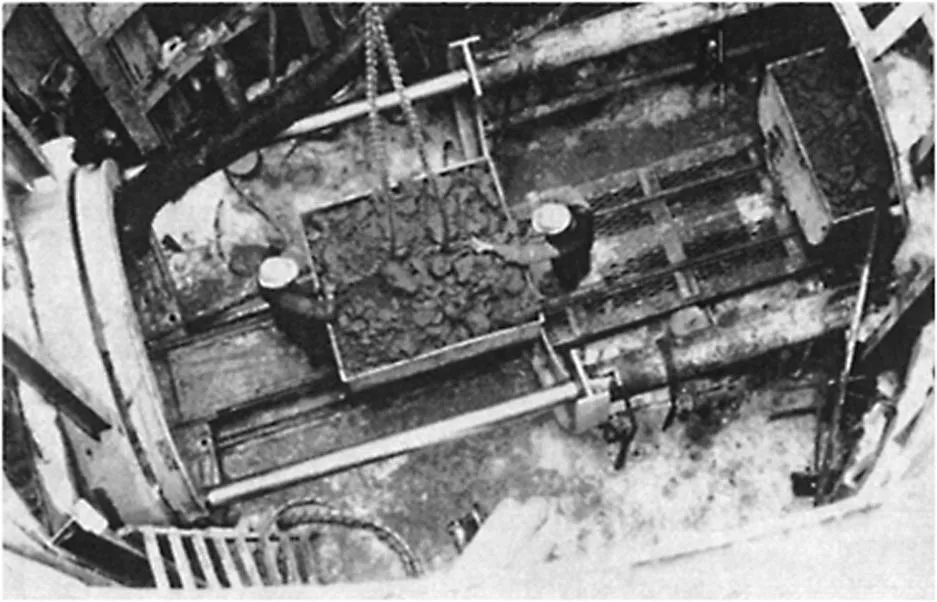

Records reveal that working methods were similar to a simple hand-mined jacking job of today. Figure 1.9 shows the plan of a jacking set-up while Figures 1.10 and 1.11 are photographs of typical operations. It would appear that although many, but by no means all, the pipes were fitted with a leading steel cutting edge, no separate adjustable shield was employed. Steering in good ground was done by excavating in front of the pipe to the course required. The devices used for jacking were probably whatever was available from other applications; reference can be found to screw jacks...

Table of contents

- Foreword

- Preface

- Contents

- 1 Development of trenchless technology

- 2 Pipejacklng and microtunnelling methods

- 3 Equipment: shields and tunnel boring machines

- 4 Pipejacking equipment: line, drive pit, top side

- 5 Equipment: microtunnelling

- 6 Design concepts

- 7 Subsurface and site investigation

- 8 Design: permanent works

- 9 Design: choice of method

- 10 Temporary work design: the line

- 11 Drive and reception pits

- 12 Design: contract documents

- 13 Site control and supervision

- 14 Economic considerations

- References

- Glossary

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Pipejacking & Microtunnelling by James Thomson in PDF and/or ePUB format, as well as other popular books in Architecture & Architecture Methods & Materials. We have over one million books available in our catalogue for you to explore.