eBook - ePub

Forensic Materials Engineering

Case Studies

- 464 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Most books on forensic engineering focus on civil engineering failures rather than consumer or general mechanical products. Unique both in scope and style, this treatment is built upon case studies of real accidents, broadly focused on consumer products, and dedicated to problem solving through scientific principles. Each well-illustrated case stud

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Introduction

1

The subject of this book is forensic engineering, an area of engineering that has grown substantially in recent years as product users have demanded everincreasing levels of quality. Premature product failure cannot only deprive the user of that product, but it can also lead to personal injury and other detrimental effects. If a ladder suddenly collapses due to the fracture of a key part, the user may be thrown off and sustain injury. If the radiator of a new car suddenly runs dry and the engine seizes up, the owner will want redress.

These are all examples of problems to which the forensic engineer can make a neutral and objective contribution in helping to investigate and determine the cause of the accident. It is also a subject that has grown with the application of new investigative tools such as Fourier transform infrared spectroscopy (FTIR) and scanning electron microscopy (SEM), techniques also used widely by forensic scientists. Consideration of the documentary evidence that inevitably accompanies any dispute that leads to court action is also a task that forensic engineers can perform. Thus engineering drawings of a product are or become available during disputes, and they may need to be interpreted for dimensional tolerances or any other feature that may have caused a problem.

1.1 Forensic Engineering

What is forensic engineering? To answer the question, we need to look at the meaning of the words (an activity that we will encounter later when discussing intellectual property matters). Consultation of Chambers English Dictionary gives the following definitions:

Forensic = 1. belonging to courts of law

2. appropriate to, or adapted to, argument

3. loosely, of or pertaining to sciences or scientists connected with legal investigations

2. appropriate to, or adapted to, argument

3. loosely, of or pertaining to sciences or scientists connected with legal investigations

Engineering = the art or profession of an engineer

Engineer = one who designs, or makes, or puts to practical use, engines or machinery of any type

Thus forensic engineering could mean, under the loose meaning of (3) above, “of or pertaining to engineers connected with legal investigations.” But with which legal investigations is a forensic engineer concerned? Such investigations could include:

- Product failure (e.g., breakage of a critical part of a product as in the ladder case just mentioned)

- Process failure (e.g., a manufacturing process fails to achieve the intended effect)

- Design failure (e.g., many products fail prematurely)

But not all such failures lead to litigation. Product failure occurs frequently with consumer products, for example, but it is rare to resort to the law to alleviate the problem. A new car may develop an unexpected defect, such as a leaking radiator. If covered by a warranty (as most new cars are today), then the seller will repair the damage at no cost to the user. One typical condition of warranties is that the car is maintained according to the manufacturer’s instructions; if not, the warranty may be void. Product or component failure is relatively common with a wide range of products, and there are well-established routes to replacing failed products without resorting to litigation. Components with a limited life are thus routinely replaced as a precautionary measure, and others are replaced when wear becomes visible and dangerous (such as car tires). However, some failures are more critical than others, for example, because they may involve safety-critical parts. Such parts are essential to the correct functioning of a product, and their failure can lead to safety risk to the user.

A primary thesis of this book is that all unexpected failures, however trivial they might at first glance appear, should be investigated to determine the cause or causes. The more serious the failure, such as with safety-critical components, the greater the need to investigate. Thus, in the case of the faulty car radiator, if the failure led to seizure of the engine, then the consequence of the original failure is much greater expense, both to the user and the manufacturer. If seizure of the engine in turn led to a car accident, then the safety issue becomes paramount.

So what are the consequences for the manufacturers? They will be concerned about their own quality methods used to make the part that failed, whether or not there was a design defect, or the problem could have been caused by the user (e.g., by not maintaining the water level in the radiator). In most failures, it is the methods and techniques of forensic engineering that, when applied objectively, can isolate the cause or causes of failure. Action can then be taken to alleviate the problem.1–3

1.2 Causal Analysis

So what are the basic methods for determining failure modes? Some common examples illustrate methods we all use and take for granted everyday. Thus when a car fails to start on a cold, damp morning, there is a range of possible explanations that come to mind (perhaps aided by the need to meet an appointment). The battery may not be fully charged, so the engine cannot turn, or charge may be leaking away and the spark plugs not igniting the gasoline vapor in the engine. Short circuiting of charge is a common problem if the plugs are damp. Alternatively, gasoline may not be reaching the engine because the tank is empty. There is a range of possible causes that can be tackled systematically in turn to arrive at the correct failure mode. Now consider a much more serious example. A car suffers an engine compartment fire; inspection reveals a leak from a plastic fuel pipe. How could such a leak occur? Examination of the pipe shows that it could have simply slipped off while the engine was on, or alternatively, it may have fractured. The cause could have been a variety of possibilities, including use of the wrong material, aging, or chemical attack. Such a failure is clearly safety-critical, and deserves detailed investigation to determine the cause.

Both examples illustrate a central point about failure analysis: there is an implicit assumption that there are rational causes for failure and reasonably objective ways of determining those causes. Of course, it is assumed that you, the reader, have some inkling of the way such common machines operate. This may not be true of all machines, even in a domestic environment. Microwave ovens, personal computers and CD players come to mind. One way out of the impasse usually involves reading the operating manual, which provides basic guidance on common failure modes (but does not normally provide an understanding of the basic principles underlying their operation) and how to recognize their symptoms (often in the form of a “fault-finding” guide). Computers are usually supplied with their own “help” guide in the software, of no use if the computer itself crashes! Even the written guides that accompany the machine are of no use if there is a mechanical or electrical effect within the machine.

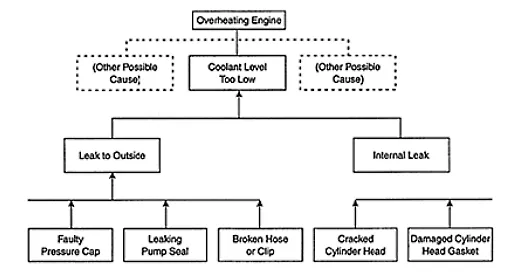

Typical fault-finding guides from car maintenance manuals (Figure 1.1) are usually tabulated and suggest several possible causes for one specific symptom. For the cooling system part of the fault-finding guide shown in the figure, five general symptoms are listed, and possible causes are provided under each heading. It is up to the user to investigate each possible fault mode systematically in turn to find the faulty component. By eliminating parts that are functioning correctly, the faulty part should be located quickly and remedial action taken. Since internal combustion engines work on the same general principles, the tabulated data are generic to many different makes of car. Such checklists are certainly a useful starting point for troubleshooting, but they must be used with common sense so that unsuspected failure modes are not discounted. Checklists often fail to mention a rather common failure mode: using the device incorrectly or in a way likely to cause failure. An example that springs to mind is spilling coffee on a computer keyboard; because water is conducting and likely to penetrate onto the printed circuit below, failure is almost inevitable. Even with simple mechanical tools such as ladders, unintended abuse by the user sometimes leads to very serious accidents.

Figure 1.1 Fault-Finding Checklist for Overheating or Overcooling of Automobile Engine

1.2.1 Fault Tree Analysis

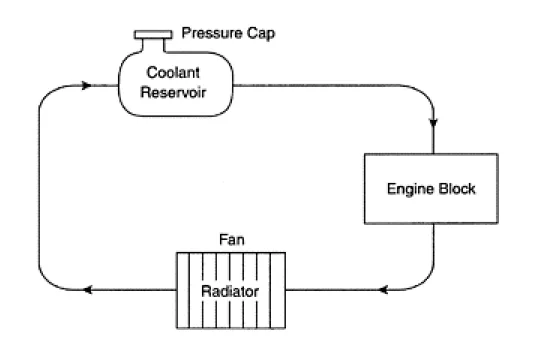

One simple way of showing the interrelationship of many different possible causes producing a single symptom is called fault-tree analysis,4 also known as cause-and-effect analysis (Figure 1.2). Thus an overheating car engine can be caused by too low a coolant level (Figure 1.1, line 1). This in turn could be caused either by internal or external leaking of the coolant. An internal leak could be caused by a broken cylinder head gasket or a cracked cylinder head. Such internal leaks usually lead to water entering the main oil sump, which turns milky by emulsification, and is instantly recognizable when seen. Alternatively, the water is leaking to the exterior environment, and possible causes include a broken hose, damaged seals (to the pump for example) or a faulty pressure cap (Figure 1.3). There are several dotted lines on the fault tree that indicate other possible causes (which might be peculiar to a particular model of a certain make of car). Fault tree diagrams are useful because they place analysis on a systematic footing, and give a mechanic or fitter a logical path to follow during examination. Each failure mode will exhibit well-defined features, so if inspection of the engine near the cooling hoses shows one point where there are dried traces of impurities from the cooling system, then the adjacent hose will need further, much closer examination.

Figure 1.2 Fault tree diagram showing causal connections for an overheating automobile engine.

Figure 1.3 Simple diagram of the cooling system of an engine.

With machines in which the working principle is totally known or if the principle of operation is known in outline form only, it is often possible to evaluate failure using common sense ideas. The basis of analysis proceeds by a logical analysis of the way failure has occurred. If the original failure is buried under consequential damage, then the task is more difficult than for simple failures. Alternatively, or in addition, the failed component may lie deep within the machine, and the failure only inferred from the lack of a particular function. However, clues to the failure may be exhibited by contact traces of wear or abrasion, for example, where none would normally be expected. Analysis of such traces is known as trace or contact analysis and can be extremely useful in locating the source of a particular problem. Forensic investigation often starts after simple inspection by a mechanic or fitter reveals a component that should not have failed, or shows defective design or manufacture, especially if the failure has led to an accident in which injuries have occurred.

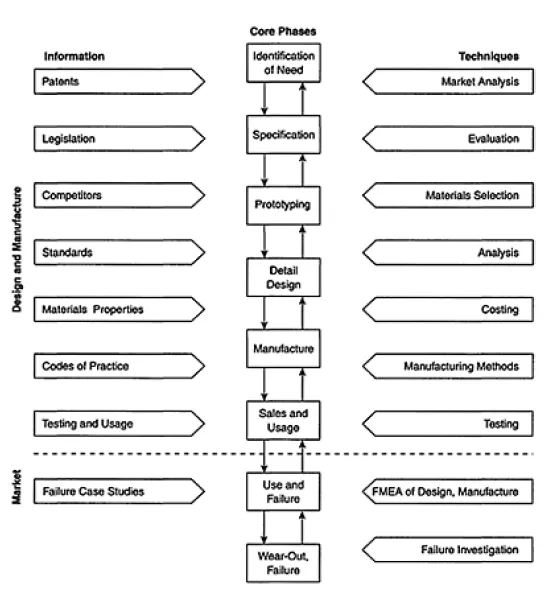

Figure 1.4 Product design flow diagram with core activities in center, information sources at left and methods at right.

1.3 Product Design and Manufacture

Manufacturing is about making products to a recognizable specification (often a Public Standard), so it is useful to consider the sequence of steps that results in a finished product (Figure 1.4). Failure to achieve a product that can survive its environment, for example, must be tackled at a very early stage in product design. This is the stage of product conception (identification of a need), followed by planning and modeling, leading to a product specification. Provided the models achieve the desired technical effect, then detailed consideration of materials of construction follows. Testing and evaluation lead to a prototype or prototypes capable of production. At all stages, study of the failure of models and prototypes is an essential part of the development process, leading to improved prototypes. The process is an iterative one, where failure at any stage causes reconsideration of the specification or materials. Such failures are, of course, a normal part of new product development.

When a successful prototype emerges, production can be planned. This is usually a costly operation due to the cost of tools and machines to run them, and demands careful planning and testing. Following product launch, when the product is sold into the open market, product failure looms large in the design equation. Product quality will be a touchstone for public perception of the product itself, so any failures require immediate attention of the design team. Failure investigation using forensic methods is the key to identifying any design flaws or production defects, and correcting them as early as possible.

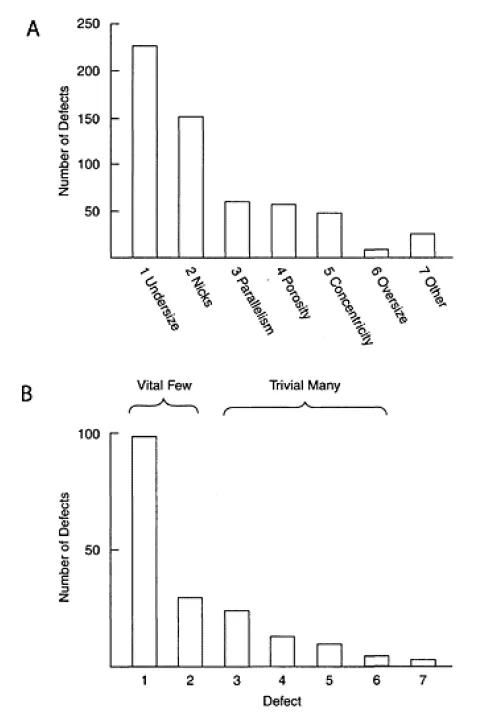

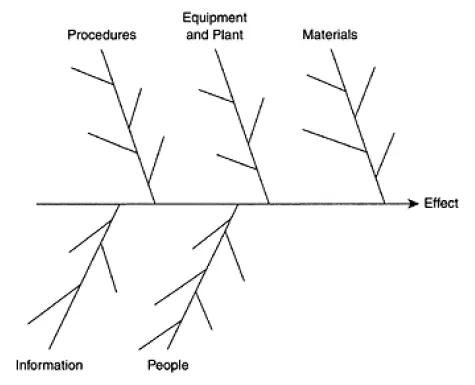

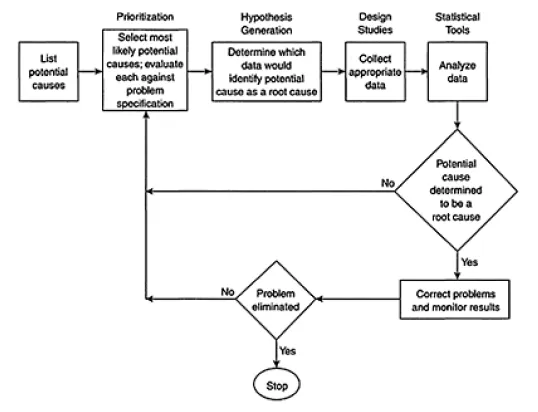

One tool for attempting to find and eliminate product defects of any kind (manufacture, design or material) before or after launch is known as Pareto analysis;4 an example of a Pareto diagram is shown in Figure 1.5. The basis of the analysis is simply the collection of failure data from the production line (usually via the quality team), and sorting of that data into generic groups. It essentially classifies product defects in terms of their importance, so that the team can gain an overview of product problems. One limitation of restricting attention to the “vital few” is that a safety-critical defect among the “trivial many” may cause greater problems in the long term. Similar statistical methods form part of reliability engineering, now just another tool in total quality management, or TQM.4 The team can then concentrate on those most serious defects, using fault tree analysis. A related method when applied in mass manufacturing industry is CEDAC (cause-and-effect-with- added-cards), using diagrams such as that shown in Figure 1.6, and flow charts similar to that shown in Figure 1.7 to find “root causes.”4

Another technique of some value in tackling product defects is known as failure modes and effects analysis, or FMEA.* This technique is in wide-spread use in many industries, and required by many standards and codes of practice. It is based on assessment of the real or suspected defect in terms of three criteria—occurrence, severity and detection—and is discussed further below. All such techniques are, however, simply management tools to allow design and production engineers a way of interacting and talking to one another in a systematic fashion about product failures and the effects that led to failure. If there is no deep appreciation of product defects and their criticality, no management or statistical method will solve the problems of product failure.

Figure 1.5 (A) Pareto diagram for several types of defects. (B) Interpretation of Pareto diagram.

Figure 1.6 CEDAC or cause-and-effect diagram, also known as an Ishekawa diagram.

Figure 1.7 Flowchart for finding the root cause(s) of a problem.

1.4 Product Defects

What are some of the common defects found in products? The first task is to define more closely the meaning of the word “defect.” One working definition might state that

a defect is a feature or characteristic of a product or component which inhibits or prevents the correct functioning or processing of that product or component

The term “feature” is used in a neutral way to denote any characteristic of a product or component that does not normally appear in a specification (such as an engineering drawing). Thus variations in surface texture often appear on plastic moldings or cast metals as a result of the manufacturing process. The definition of features, which are also defects, is useful because it immediately allows us to examine those features that can affect product function in more detail. There are at least two types of defects:

- Those already present in the product before sale or use which lead quickly to rejection or functional failure (in which case they are clearly defects), and

- Defects that develop over time in a product, and so can increase the failure rate after normal use of the product

Such an approach exceeds the narrow legalistic view of defects. For example, the U.K. Consume...

Table of contents

- Cover Page

- Title Page

- Copyright Page

- Dedication

- Preface

- Acknowledgments

- The Authors

- Introduction: 1

- Materials in Distress: 2

- Establishing the Load Transfer Path: 3

- A “Toolbox” for Forensic Engineers: 4

- Failure Due to Manufacturing Faults: 5

- Fluid Transport: 6

- Failure of Storage Vessels: 7

- Accidents in the Workplace: 8

- Failure of Medical Implements: 9

- Component Failure in Road Traffic Accidents: 10

- Fraudulent Insurance Claims: 11

- Criminal Cases: 12

- Intellectual Property Cases: 13

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Forensic Materials Engineering by Peter Rhys Lewis,Ken Reynolds,Colin Gagg,Colin Gagg in PDF and/or ePUB format, as well as other popular books in Law & Civil Engineering. We have over one million books available in our catalogue for you to explore.