Industrial Automation Technologies

- 354 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Industrial Automation Technologies

About this book

The book begins with an overview of automation history and followed by chapters on PLC, DCS, and SCADA –describing how such technologies have become synonymous in process instrumentation and control. The book then introduces the niche of Fieldbuses in process industries. It then goes on to discuss wireless communication in the automation sector and its applications in the industrial arena. The book also discusses theall-pervading IoT and its industrial cousin,IIoT, which is finding increasing applications in process automation and control domain. The last chapter introduces OPC technology which has strongly emerged as a defacto standard for interoperable data exchange between multi-vendor software applications and bridges the divide between heterogeneous automation worlds in a very effective way.

Key features:

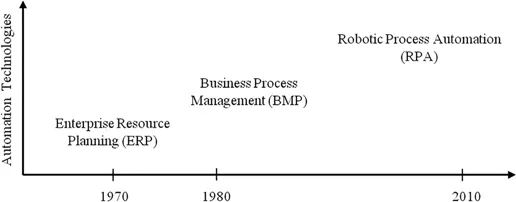

- Presents an overall industrial automation scenario as it evolved over the years

- Discusses the already established PLC, DCS, and SCADA in a thorough and lucid manner and their recent advancements

- Provides an insight into today's industrial automation field

- Reviews Fieldbus communication and WSNs in the context of industrial communication

- Explores IIoT in process automation and control fields

- Introduces OPC which has already carved out a niche among industrial communication technologies with its seamless connectivity in a heterogeneous automation world

Dr. Chanchal Dey is Associate Professor in the Department of Applied Physics, Instrumentation Engineering Section, University of Calcutta. He is a reviewer of IEEE, Elsevier, Springer, Acta Press, Sage, and Taylor & Francis Publishers. He has more than 80 papers in international journals and conference publications. His research interests include intelligent process control using conventional, fuzzy, and neuro-fuzzy techniques.

Dr. Sunit Kumar Sen is an ex-professor, Department of Applied Physics, Instrumentation Engineering Section, University of Calcutta. He was a coordinator of two projects sponsored by AICTE and UGC, Government of India. He has published around70 papers in international and national journals and conferences and has published three books – the last one was published by CRC Press in 2014. He is a reviewer of Measurement, Elsevier. His field of interest is new designs of ADCs and DACs.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Industrial Process Automation

1.1 DEFINITION OF PROCESS

1.2 MEANING OF AUTOMATION AND CONTROL

- An automation system may include a control system, but the reverse is not necessarily true.

- The main function of any control system is to ensure that output must follow the set point or desired value. However, automation systems may contain more functionalities, such as computing set points for control system, monitoring system performance, plant startup or shutdown, job and equipment scheduling, etc.

- The job of a controller is essentially to capture a process variable and to compare the same with the set value to produce necessary control action, thus ensuring that in the steady state, the value of the process variable is in line with the specified set values.

- A controller is the most important block for running a plant/process in a desired manner; otherwise, without control, it would result in the process variables deviating from the set value. So, the use of controllers is vital with respect to economy, reproducibility, product quality, service quality, safety, and environmental protection.

- In order to meet these criteria, plant operators always try to continuously improve upon automation systems. Starting with classical pneumatic Proportional-Integral-Derivative (PID) controllers of early days, at present software-based digital PID controllers are being increasingly employed.

- In addition to PID controllers, various other additional features like data acquisition, sequencing, recipe scheduling, alarm handling, etc. are incorporated in plant automation.

1.3 NECESSITY AND EVOLUTION OF AUTOMATION

- Flexibility: The need to stay ahead in the competition and to get improved product quality requires reconfiguring assembly lines and redesigning processing facilities.

- Quality control: Today’s quality assurance (QA) or quality control (QC) demands high levels of coordinated data acquisition and analysis.

- Inventory control: Just-in-time business strategies mean lower overhead by reducing or eliminating warehousing needs.

- Speed: People who need products are also operating on just-in-time principles. If the same is not delivered on time, they would lose production time, and the suppliers of these products would ultimately lose customers.

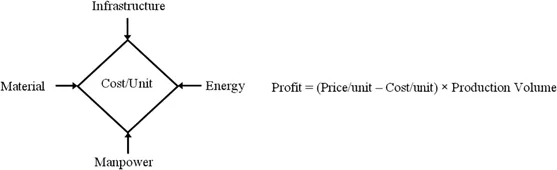

1.4 ROLE OF AUTOMATION IN PROCESS INDUSTRY

- Reduced production cost: A quick return on investment (ROI) outweighs the initial setup costs.

- Decreased part cycle time: Robotics can work longer and faster, which increases the production rate.

- Improved quality and reliability: Automation is precise and repeatable, which ensures the product is manufactured with the same specifications each time.

- Better floor space utilization: Reduced work area by automating the parts in a production line; the floor space can be better utilized for other operations and make the process flow more efficient.

- Reduced waste: Robots are so accurate that the amount of raw material used can be reduced, decreasing costs on waste.

- Staying competitive: Automation helps to achieve the highest throughput while keeping the production schedule and cost within the specified constraints.

1.5 ARCHITECTURE OF INDUSTRIAL AUTOMATION NETWORK

- Field level: The field level comprises sensors, actuators, switches, etc. which are installed in the tanks, vessels, and pipelines that make up a process plant. Sensors provide information about the process variables (temperature, pressure, flow, level, etc.) and pass the signals to the I/O (input/output) level. These signals are then passed on to the actuators which control the opening/closing of valves or start/stop of pumps.

- I/O level: The main purpose of the I/O level is to marshal together input and output signals. The signals from the sensors are directed to the controllers and those from the controllers are directed to the actuators.

- Control level: At the control level, signals from the sensors (located in the field) are processed, and based on the desired process outputs, commands to the actuators are generated. Usually Programmable Logic Controller (PLC), Distributed Control System (DCS), and Supervisory Control And Data Acquisition (SCADA) are present in this layer.

- HMI level: The Human Machine Interface (HMI) level is primarily concerned with the organized and systematic display of plant operations passed from the control level. Data acquisition, recipe management, asset management, maintenance schedule tools etc. are used in this layer for better process management. Operators have entire plant information through schematic represe...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Contents

- Preface

- Acknowledgements

- About the Authors

- Chapter 1 Industrial Process Automation

- Chapter 2 Programmable Logic Controller (PLC)

- Chapter 3 Distributed Control System (DCS)

- Chapter 4 Supervisory Control and Data Acquisition (SCADA)

- Chapter 5 Fieldbus

- Chapter 6 Wireless Sensor Networks (WSNs)

- Chapter 7 Industrial Internet of Things (IIoT)

- Chapter 8 Open Platform Communications (OPC)

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app