- 240 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Supply Chain Management for Engineers

About this book

Originally taught mainly in business schools, supply chain management has become a common elective and graduate course in engineering colleges. The increasing demand for engineers with supply chain knowledge has fed this shift. However, supply chain management textbooks that have a reasonable coverage of quantitative analysis techniques are few and

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Designing and Engineering the Supply Chain for Competitive Advantage

1.1 Overview

Generally speaking, a supply chain is a network of facilities that procure raw materials, transform them into intermediate goods and then final products, and deliver the products to customers through a distribution system. It encompasses all the information, financial, and physical flows from the supplier’s supplier to the customer’s customer. Consider the automotive industry; the development, design, production, marketing, and delivery of new cars is a team effort that begins with extracting raw materials from the earth, continues through design, fabrication, and assembly, and ends with fit and finish in the dealer’s showroom. When a customer buys a car, the customer chooses the output of the entire supply chain and pays all the participants. To be successful, automotive companies must develop an approach to design, organize, and execute supply chain activities from its roots in basic materials extracting to the dealer network. This does not mean ownership or even direct control, but it does imply mechanisms that influence decision making and impact system-wide performance.

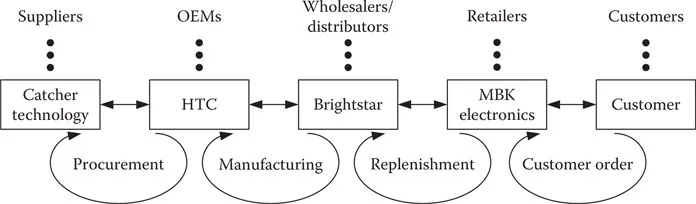

A typical supply chain involves the following stages: (1) raw material/component suppliers, (2) original equipment manufacturers (OEMs), (3) wholesalers/distributors, (4) retailers, and (5) customers. Consider the case of a customer purchasing an HTC mobile phone from an electronics store at MBK Bangkok, which is one of the best shopping malls in Thailand. The electronics store, a retailer, offers a variety of mobile phones and other electronics products for the customer to choose from. It obtains mobile phones from Brightstar, a distributor of various wireless devices produced by Apple, Nokia, HTC, and other OEMs. HTC, an OEM, obtains metal cases for its mobile phones from Catcher Technology, a component supplier. The customer, MBK electronics store, Brightstar, HTC, and Catcher Technology are different stages in a mobile phone supply chain. Each stage is connected through the flow of materials, information, and funds. A distinct process cycle occurs between two successive stages of the supply chain, resulting in a total of four process cycles, as shown in Figure 1.1. These process cycles are summarized as follows:

A typical supply chain and its process cycles.

• Customer order process cycle. This process cycle occurs between the customer and the retailer. A customer arrives at the MBK electronics store and decides to purchase an HTC mobile phone. The store processes this information and fulfills the customer’s order. The customer receives the HTC mobile phone that he/she desires. Funds are transferred from the customer to the electronics store.

• Replenishment process cycle. This process cycle occurs between the retailer and the wholesaler/distributor. As the inventory of mobile phones at the MBK electronics store decreases to a certain level because of fulfilling customer orders, the electronics store places an order to Brightstar. Brightstar processes this information and sends a shipment to the electronics store. The electronics store replenishes its inventory. Funds are transferred from the electronics store to Brightstar.

• Manufacturing process cycle. This process cycle occurs between the wholesaler/distributor and the OEM. To replenish its inventory of HTC mobile phones, Brightstar places an order to HTC. HTC schedules its production based on order information. It then produces and ships the ordered mobile phone to Brightstar. Brightstar replenishes its inventory. Funds are transferred from Brightstar to HTC.

• Procurement process cycle. This process cycle occurs between the OEM and the raw material/component supplier. HTC orders metal cases for its mobile phones from Catcher Technology based on its production schedule. Catcher Technology schedules its production based on order information. It then produces and ships the ordered metal cases to HTC. HTC receives the metal cases for its production. Funds are transferred from HTC to Catcher Technology.

Note that the previous description is a simplified version of a mobile phone supply chain focusing on a single entity in each stage of the supply chain. In reality, the MBK electronics store sells products obtained from different wholesalers/distributors. It could also obtain products directly from certain OEMs. Brightstar supplies thousands of retailers worldwide. When it orders mobile phones from HTC, Brightstar aggregates demand from all the retailers it supplies. In addition to HTC, Brightstar provides value-added distribution services for many other OEMs. On the other hand, HTC also provides mobile phones to different wholesalers/distributors. Other than mobile phones, HTC manufactures products such as tablets. When it schedules production, HTC aggregates demands of different products from all of its customers. In the production process, HTC requires many other components in addition to metal cases for mobile phones. Therefore, it has many suppliers in addition to Catcher Technology. Besides HTC, Catcher Technology supplies metal cases to other OEMs as well. Therefore, it also uses aggregated demand information from all of its customers for production scheduling. In summary, the supply chain relationships among different companies are complex and require a systematic management strategy.

A supply chain derives its revenue from the customer. It incurs various costs in providing products and services to the customer. The difference between the revenue generated and the overall costs across the supply chain is the supply chain profitability. This is the profit to be shared across all supply chain stages. If each stage of the supply chain aims to maximize its own profit without considering the entire supply chain, it may result in lower supply chain profitability. Therefore, the objective of a supply chain should be to maximize its profitability by carefully managing its assets, products, information flow, and logistics.

The idea of supply chain management is to view the chain as an integrated system and to fine-tune the decisions about how to operate the various components (companies, functions, and activities) in ways that can produce the most desirable overall system performance in the long run. Supply chain management is made possible by the dramatic development of information technology in the last several decades, while its seed was sown during World War II when manufacturers were using systems capable of mass producing standardized products efficiently. Emerging from World War II, demand for all kinds of consumer products created large back orders. In this environment, variety was limited and a manufacturer’s competitive strength lay in low-cost production and exploiting economies of scale. In the late 1970s, with a decline in their share of the world markets, U.S. manufacturers recognized that the price and quality of their products made them less competitive. They thus adopted the total quality management (TQM) paradigm and regarded price and reduced lead time as the market qualifier. Gradually, customers began to demand high-quality products with low price and short lead time. This forced manufacturers to reexamine the mass production concept to reveal previously “hidden” costs (due to the prevalent costing system at the time) such as inventory, quality, and overheads. Another realization was that success in the global economy would be achievable only if distinct market segments were identified and targeted and products were custom-made to suit the customer’s individual needs. Manufacturers were thus forced to develop new methodologies and tools to face product customization and lead time reduction. This gave rise to the supply chain management concept, which integrates suppliers, manufacturers, wholesalers/distributors, retailers, and customers to (1) reduce costs over the entire chain and (2) respond quickly to customer needs.

Supply chain management is inherently multidisciplinary and requires the efforts of both engineers and business managers. Broadly speaking, engineers deal with design and development of technologies and models of supply chain, whereas business managers work on the development and implementation of strategies for the framework of supply chain models. In practice, business strategy dictates supply chain strategic decisions, whereas technologies and models are tools to facilitate the execution of these decisions. Therefore, successful supply chain management requires both the understanding of the strategies behind supply chain design and the mastery of supply chain modeling and optimization techniques.

This book is written for engineers with an emphasis on modeling and optimization techniques. However, engineers also need to have a clear understanding of strategic issues in supply chain management. The rest of the chapter will provide an overview of such issues, including the types of supply chains, methods for designing supply chains, supply chain process models and performance metrics, and drivers to improve supply chain performance.

1.2 Supply Chain Types

Vonderembse et al. (2006), after a careful review of the literature, defined three types of supply chains, summarized as follows:

• Lean supply chain. A lean supply chain (LSC) employs continuous improvement efforts that focus on eliminating waste or nonvalue-added steps along the chain. It is supported by efforts to achieve internal manufacturing efficiencies and setup time reduction, which enable the economic production of small quantities and enhance cost reduction, profitability, and manufacturing flexibility to some degree. The short setup time provides internal flexibility, but an LSC may lack external responsiveness to customer demands, which can require flexibility in product design, planning and scheduling, and distribution in addition to manufacturing.

• Agile supply chain. An agile supply chain (ASC) focuses on responding to unpredictable market changes and capitalizing on them through fast delivery and lead time flexibility. It deploys new technologies, methods, tools, and techniques to solve unexpected problems. It utilizes information systems and technologies, as well as electronic data interchange capabilities to move information faster and make better decisions. It places more emphasis on organizational issues and people (knowledge systems and empowered employees), so decision making can be pushed down the organization. The ASC paradigm is a systemic approach that integrates the business, enhances innovations across the company, and forms virtual organizations (VOs) and production entities based on customer needs.

• Hybrid supply chain. A hybrid supply chain (HSC) generally involves “assemble to order” products whose demand can be forecasted with a relative high level of accuracy. The chain helps to achieve mass customization by postponing product differentiation until final assembly. The lean or agile supply chain techniques are utilized for component production with different characteristics. For example, in the automotive industry, air bags would most likely be produced with an LSC while engine electronics might require the innovation found in an ASC. In addition, the agility is needed to establish a company–market interface to understand and satisfy customer requirements by being responsive, adaptable, and innovative.

A more detailed description of LSC, ASC, and HSC is provided in Table 1.1. These supply chain types are, to a large extent, a function of product characteristics and customer expectations (Fisher 1997). With a rapidly changing business environment, organizations require a supply chain model that deals with strategic and customer issues in addition to operating constraints. The product is the soul of the supply chain; there is no justification for adopting a particular supply chain type unless it conforms to the needs of the product and its customers. Three case studies are presented next to help the reader better understand the relationships between supply chain types and product characteristics.

Case Study 1.2.1 Black and Decker’s Lean Supply ChainBlack and Decker Inc. (now Stanley Black & Decker) produces a variety of small appliances and hand tools for use in the home. Success in that market is predicated on manufacturing products that have high quality and low cost and a moderate amount of variety. Designs for these appliances and tools change slowly, and demand for these products can be characterized as slow and steady growth. Under these circumstances, an LSC effectively meets the needs of Black and Decker. An LSC focuses on operating issues as it attempts to eliminate nonvalue-added operations. LSC partners support the reduction of setup time to enable the economic production of small quantities. This enables the supply chain to keep i...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Preface

- Author

- 1. Designing and Engineering the Supply Chain for Competitive Advantage

- 2. Understanding Customer Demand: Forecasting

- 3. Matching Supply with Demand: Aggregate Planning

- 4. Satisfying Customer Demand: Inventory Management

- 5. Moving Products across Supply Chain: Distribution Network Design and Transportation Decision Making

- 6. Supplier Selection Methodology

- 7. Supply Chain Simulation Game

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Supply Chain Management for Engineers by Samuel H. Huang in PDF and/or ePUB format, as well as other popular books in Business & Operations. We have over one million books available in our catalogue for you to explore.