eBook - ePub

Available until 8 Jun |Learn more

Cause, Effect, and Control of Accidental Loss with Accident Investigation Kit

This book is available to read until 8th June, 2026

- 280 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Available until 8 Jun |Learn more

Cause, Effect, and Control of Accidental Loss with Accident Investigation Kit

About this book

Accident: an undesired event that results in loss. Most people give little thought to accidents or their prevention. Health and safety professionals face this challenge, and its associated costs and losses, both human and financial, every day. Cause, Effect, and Control of Accidental Loss with Accident Investigation Kit provides the tools you need

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Cause, Effect, and Control of Accidental Loss with Accident Investigation Kit by Ron Charles McKinnon in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Industrial Engineering. We have over one million books available in our catalogue for you to explore.

Information

CHAPTER ONE

FAILURE TO ASSESS RISKS

Failure to identify the hazards, analyze and evaluate the risk, and set up control measures triggers off a chain of events that lead to accidental loss.

Control

Failure to identify the risks brought about by the business leaves the elements and items that need to be controlled unidentified.

As a result of poor controls, personal and job factors arise that lead to the creation of unsafe work conditions and the unsafe acts of people. These eventually lead to the contact, the property damage, and/or the injury. This chain of events culminates in the last domino in the “Cause, Effect, and Control of Accidental Loss” (CECAL) sequence, which is financial losses. “Effective health and safety management is not ‘common sense’ but is based on a common understanding of risks and how to control them brought about through good management.” (Health and Safety Executive, Great Britain, 1991). Dan Petersen (1998), states that: “If a firm can dictate, in advance, what actions it should take to prevent accidents, then it can measure how well these predetermined actions are executed.” (p.37) Risk assessment is a method that is predictive and can indicate potential for loss. With this knowledge an organization is then able to set up the necessary management controls to prevent these risks resulting in losses such as injuries, property damage, business interruptions, and environmental pollution. Many safety programs focus on the consequence of loss and not the control. Effective risk assessment is proactive, predictive safety in the finest form. In risk assessment the keywords are, “It’s not what happened, but what could have happened.”

Vernon L. Grose (1987) talks about the risk management approach as follows:

The systems approach is a means of looking at even a very large problem in its entirety. You can start by calling whatever you are trying to manage – company, agency, product, family, organization, project, or farm – a system. Then you mark off its boundaries and define its inputs and outputs, (p. 11)

Grose says that this allows one to attack all the risks at one time.

Risk

A risk can be defined as any probability or chance of loss. It is the likelihood of an undesired event occurring at a certain time under certain circumstances. The two major types of risks are speculative risks where there is the possibility of both gain and loss, and pure risk, which offers only the prospect of loss.

Risk Management

Risk management combines the safety management functions of safety planning, organizing, leading, and controlling of the activities of a business so as to minimize the adverse effects of accidental losses produced by the risks arising from the organization.

Physical Risk Management

Physical risk management and financial risk management are the two main components of the science of risk management and the best indicator for safety controls is physical risk management.

Physical risk management consists of identifying the hazards, assessing the risks, evaluating them, and introducing the necessary controls to reduce the probability of these risks manifesting in loss.

Risk Assessment

Risks cannot be properly managed until they have been assessed. The process of risk assessment can be defined as the evaluation and quantification of the likelihood of undesired events and the likelihood of injury and damage that could be caused by the risks. It also involves an estimation of the results of undesired events occurring. One of the biggest benefits of risk assessment is that it will indicate where the greatest gains can be made with the least amount of effort and which activities should be given priority. The safety practitioner now has a prioritization system based on sound risk assessment practices.

Components

Risk assessment has three major components:

1. hazard identification

2. risk analysis

3. risk evaluation

Once the three phases of risk assessment are completed, risk control is then implemented. Risk control can only be instituted once all hazards have been identified and all risks quantified and evaluated. There is a substantial difference between a systematic approach to workplace health and safety and a behavioral-based safety approach. (Jim Howe)(1998, p.20) Howe further says, “The systems approach takes an objective and unbiased view of the workplace by:

1. identifying hazards

2. estimating the level of risk for each hazard

3. controlling hazards according to the hierarchy”

According to Grose (1987), its identification process limits a risk prevention program. “If a risk is not first identified, it can never be evaluated or controlled.” (p. 13)

1. HAZARD IDENTIFICATION

The first step of a risk assessment is the identification of all possible hazards. A hazard is a situation that has potential for injury or damage to property or the environment. It is a situation or action that has potential for loss.

There are numerous hazard identification methods and techniques. The two main techniques are the comparative and the fundamental methods. Fundamental techniques include Hazard and Operability studies (HAZOP); Failure Mode and Effect Analysis (FMEA); Failure Mode, Effect, and Critical Analysis (FMECA); checklists, and other techniques such as:

• hazard surveys

• hazard indices

• accident reports

• near-miss reports

• critical task identification

• safety audits

Comparative techniques use checklists based on industry standards or existing codes of practice. They could involve comparing the plant in question with similar plants.

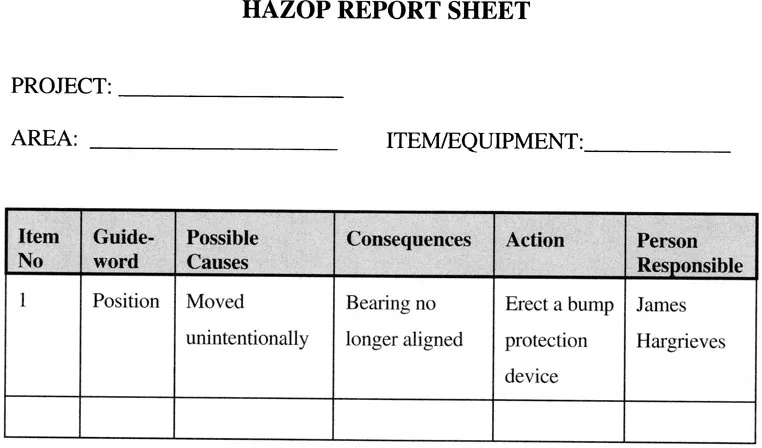

HAZOP

According to Grant Purdey, (1996),

A “HAZOP” involves taking a component (e.g. a valve, or an element of procedure) and stressing it beyond its designing tension and normal operation. In the tradition of HAZOP, nodes of a plant are subject to guidewords applied to relevant physical properties such as flow, temperature and pressure. Then a potential cause of such a deviation is sought, and a consequence defined. If the consequence is undesirable then the hazard has to be addressed by removal, mitigation or control, (p.411)

Model 1.1 - A HAZOP Report Sheet showing the guidewords used, possible causes, consequences and mitigating action with responsibility delegated.

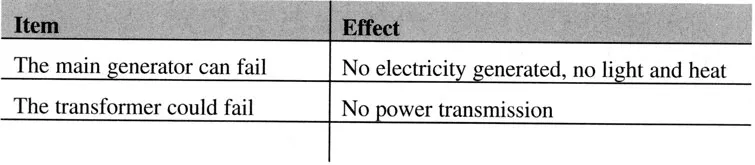

FMEA (Failure Mode and Effect Analysis)

The Failure Mode and Effect Analysis is another method of identification of hazards. This method is used for identifying possible failures in the system and resulting consequences. FMEA asks the question, “What system could fail and what would the effect be?”

An example of a FMEA method of hazard identification is given in Model 1.2, which shows extracts of a risk assessment done in a power-generating unit. The FMEA exercise identified the main systems, which could fail within the department and the consequences as a result of main system failures.

What can fail and what will the effect be? (Use normal expected loss).

Model 1.2 - Hazard identification: FMEA.

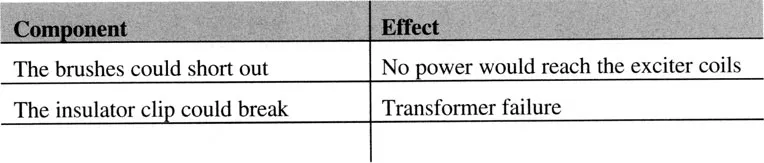

FMECA (Failure Mode, Effect, and Criticality Analysis)

The Failure Mode, Effect, and Criticality Analysis (FMECA) is a hazard identification method that goes into more depth than the FMEA. The FMECA method examines each component of a system for criticality and identifies the effect on the entire system upon failure of components. This helps focus on critical components within a unit.

Model 1.3 shows an FMECA analysis of a risk assessment. What components are critical to the process and what will the effect be if they fail?

Model 1.3 - An example of a FMECA analysis.

Event Tree Analysis

The Event Tree Analysis (ETA) is a predictive method of determining the cause and effect of events. The ETA starts with the event and deduces by means of Boolean logic what factors could contribute to the event. Fault Tree Analysis (FTA) is deductive as it deduces the events and sub-events that lead to the main event using the same method as Event Tree Analysis.

Past Accidents and Incidents

A useful method of predicting future hazards is to review past injury and property damage causing accidents as well as near-miss events. By studying past loss-producing events, a pattern can be derived that would indicate certain recurring and inherent hazards within the business.

Near-misses, or events, which under slightly different circumstances could have resulted in a loss, are perhaps the best indicators of the presence of hazards arising from the risks of the business.

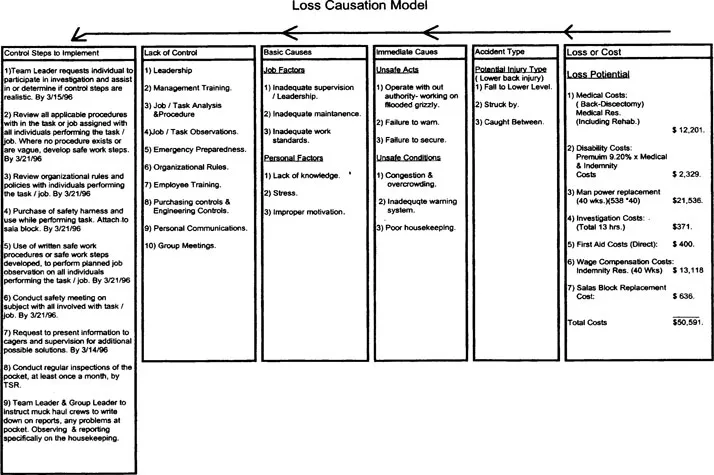

Model 1.4 - Loss causation analysis of a near-miss.

Case Study

The case study on a near-miss incident clearly indicated 10 major hazards that existed that could have resulted in accidental losses in excess of $50,000. These hazards included poor leadership, lack of management training, no emergency preparedness, and little or weak employee training. These hazards extended to the purchasing and engineering controls. This example clearly indicates that near-misses can often highlight hazards that can then be controlled before the loss occurs. Formal and informal incident-recall sessions are imperative if hazard identification is to b...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Preface

- Data Collection

- Acknowledgments

- 1 Failure to Assess Risks

- 2 Lack of Safety Management Control

- 3 Basic Causes of Accidental Loss

- 4 Unsafe Acts and Conditions

- 5 Luck Factor 1

- 6 Under Slightly Different Circumstances

- 7 Potential for Loss

- 8 Exchange of Energy

- 9 Luck Factor 2

- 10 Injury, Illness, and Disease

- 11 Property and Equipment Damage

- 12 Business Interruption

- 13 Luck Factor 3

- 14 Severity of Injury

- 15 Costs of Accidental Loss

- References

- How to Investigate an Accident