- 344 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Warp Knitted Fabrics Construction

About this book

The aim of this book is to provide the background of the warp knitting patterning with a large amount of simulated 3D images of the structures, corresponding to the modern available tools for this. The warp knitted structures can have very complex architectures and very limited understanding exists on how they are built. The pattern book will allow

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Warp Knitted Fabrics Construction by Yordan Kyosev in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Industrial Engineering. We have over one million books available in our catalogue for you to explore.

Information

Part I

Fundamentals of warp knitting

1

Warp knitting process fundamentals

1.1 Introduction

This chapter provides information about the warp knitting process, limited to the patterning related topics. More details about the knitting process, the working cycle of the machine, different configurations of machine elements and so on can be found in several books such as [4], [24], [26], [18].

1.2 Knitting process and pattern notation

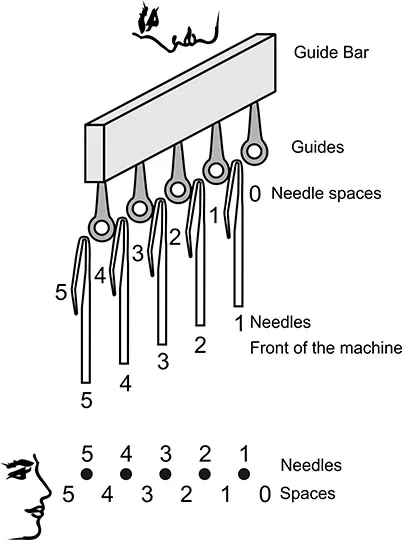

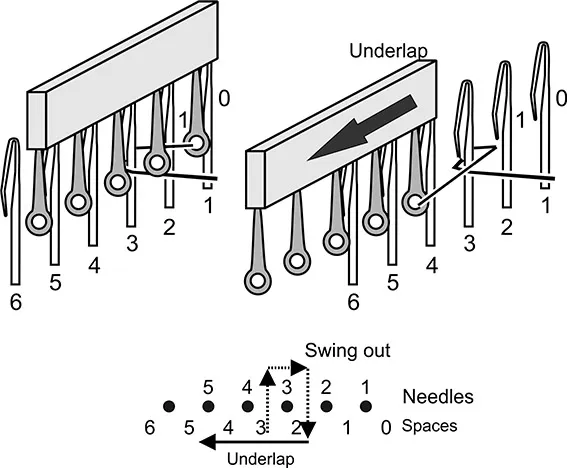

Each warp yarn, used for production of warp knitted fabrics, is formed from a single guide. Several guides are grouped into guide bar, as shown in Figure 1.1. Each guide bar moves around the needles and places the yarn over, between and after or behind these during the production process. The needles, the spaces between them and the guides are numbered, starting from the side, where their pattern drive (cam, chain links, electronic drive) is mounted. Usually, the pattern drive is placed on the right hand side of the machine and the needles, and the guides are numbered from right to the left. For the graphical notation of the warp knitted structures, the complete motion process of the guides is recorded symbolically on paper. For this notation, the person has to assume, that is looking at the needles from the top (Figure 1.1 upper picture), but for simplification, only the needle cross section is drawn as a thick point. For each knitting cycle, one row with points and spaces between these is used.

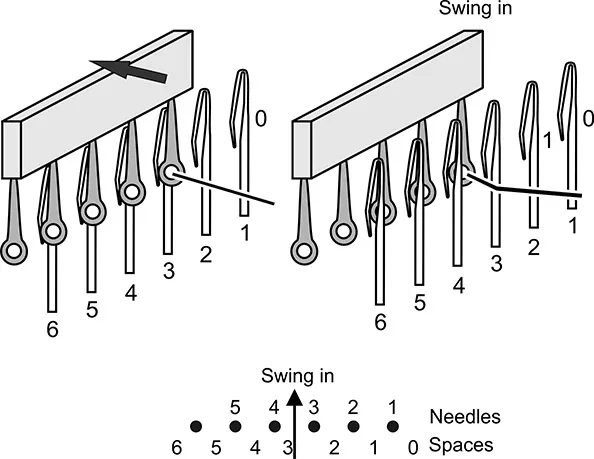

Let the guide bar have only one yarn on its guide number one (Figure 1.2). During the knitting process, the guide moves between the needles and this motion step is named “swing in”-the needles motion. The gab number, where the first guide of one bar is swinging-in, is used for numerical notation of this motion step; in the case of Figure 1.2, this is the number 3. On the drawing, a short line (or curve) between the dots is drawn.

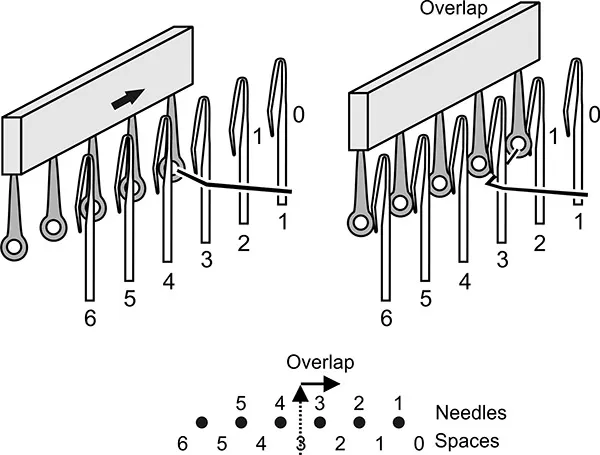

After the placing the yarn(s) between the needles the guide bar is moving to left or right in the front of the needles, placing yarn over them - overlapping (Figure 1.3). The overlapping is a shog over one or seldom over two needles. The limitation to one or two needles is based on the need of the yarn length for the loop building process. If yarn is placed over more than two needles, during building of the loops there will be not enough yarn length for more loop heads, legs and underlaps and the yarn will break. In pattern drawing this step is drawn as a small arrow or arc over the point. If no loop has to be built, then the guide bar stays there and does not perform any motion during this step.

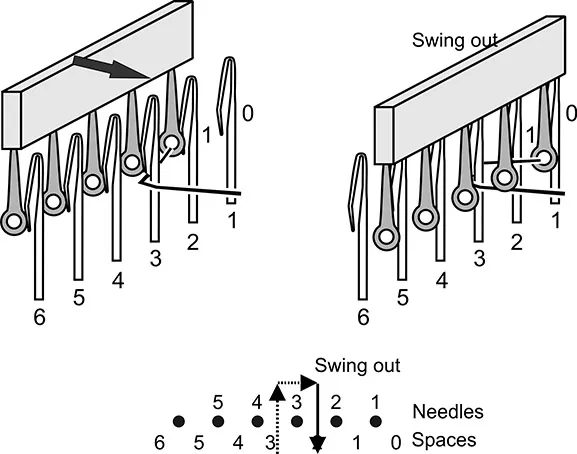

The next step is the swing out - the guides are swinging through the gaps between the needles back. The gap number, where the first guide goes through is used for the numerical notation of the pattern, in the case of the Figure 1.4 this is the number two. On the drawing, this motion is represented by a short line or curve between the points.

Finally, the guide bar moves behind the needles and the guides place their yarns “under” the needles (Figure 1.5). The motion is named underlap. This motion is not limited to one or two needles, because the yarn does not have to build loops on this side, and the required yarn length has to be taken from the beam. The limitation of the underlap motion is determined from the patterning device - it can be often not more than 32 gaps.

After these four steps of the guide bars, the needle bar starts moving all the needles down. Theirs hook have to become closed. Depending on the needle type this happens as follow:

•the bearded needles become pressed during this period;

•the latch of the latch needle rotates, moved from the previous loop;

•the tongue of the compound needle moves and closes the hook.

The new placed yarn piece in this case remains in the needle hook and the previous loop can knock over it. After that, the needle bar moves up and the cycles start again. For each such cycle, the numbers of the swing-in and swing-out positions are notated, separated by m...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Dedication

- Contents

- Foreword

- Preface

- Author

- Symbols

- Part I: Fundamentals of warp knitting

- Part II: Loop based single face structures

- Part III: Single face structures with more structural elements

- Part IV: Structures from double needle bar machines

- Part V: Engineering design

- Bibliography

- Index