- 416 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Solid Lubrication Fundamentals and Applications

About this book

Solid Lubrication Fundamentals and Applications description of the adhesion, friction, abrasion, and wear behavior of solid film lubricants and related tribological materials, including diamond and diamond-like solid films. The book details the properties of solid surfaces, clean surfaces, and contaminated surfaces as well as discussing the structu

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Chapter 1

Introduction and Background

1.1 Definition and Scope of Tribology

Tribology is defined as “the science and technology of interacting surfaces in relative motion, and of associated subjects and practices” [1.1]. This term was introduced and defined in a report by a group set up by the British Department of Education and Science [1.2]. Tribology, having its origin in the Greek word “τριβoζ,” meaning rubbing or attrition, deals with force transference between surfaces moving relative to each other. This discipline includes such subjects as lubrication, adhesion, friction, and wear of engineering surfaces with a view to understanding surface interactions in detail (Fig. 1.1) and then prescribing improvements in given applications.

The technical function of numerous engineering systems, such as machines, instruments, and vehicles, depends on processes of motion. According to its basic physical definition the term “motion” denotes the change in the position of an object with time. Many processes in nature and technology depend on the motion and the dynamic behavior of solids, liquids, and gases (Table 1.1, [1.3, 1.4]). For example, bearings and gears permit smooth, low-friction rotary or linear movement between two surfaces (Fig. 1.2). Bearings employ either sliding or rolling action and gears have both sliding and rolling action. In these cases a strong attempt is made to provide enough lubrication to keep the bearing and gear teeth surfaces separated by a film of solid lubricant, oil, or other lubricant such as grease. The absence of physical contact provides most bearings and gears with long service lives.

Tribology is a discipline that traditionally belongs to mechanical engineering. However, with the recent push toward higher speeds, loads, and operating temperatures, longer term life, lighter weight and smaller size, and harsh environments in mechanical, mechatronic, and biomechanical systems, the field of tribology is becoming more and more interdisciplinary, embracing physics, chemistry, metallurgy, biology, and engineering.

Figure 1.1.—Definition of tribology. (a) Lubrication, (b) Adhesive bonding, (c) Wear.

Figure 1.2.—Plain bearings, rolling-element bearings, and gears, (a) Plain bearings based on sliding action, (b) Rolling-element bearings based on rolling action, (c) Gears based on rolling and sliding action.

TABLE 1.1.—TYPES OF SURFACE MOTION AND RELATED SUBJECTS

1.2 Social and Economic Impact of Tribology

The subject of tribology is identified as one of great importance; yet largely because of its multidisciplinary nature, it has received insufficient attention. As a direct result mechanical engineering design is retarded, and many tens of billions of dollars have unnecessarily been lost each year through friction, wear, related breakdowns, wasted energy, etc. These costs are the direct costs of friction and wear. Consideration must also be given to the indirect costs, such as loss of production, product liabilities, failure to accomplish a significant mission, or standby maintenance costs.

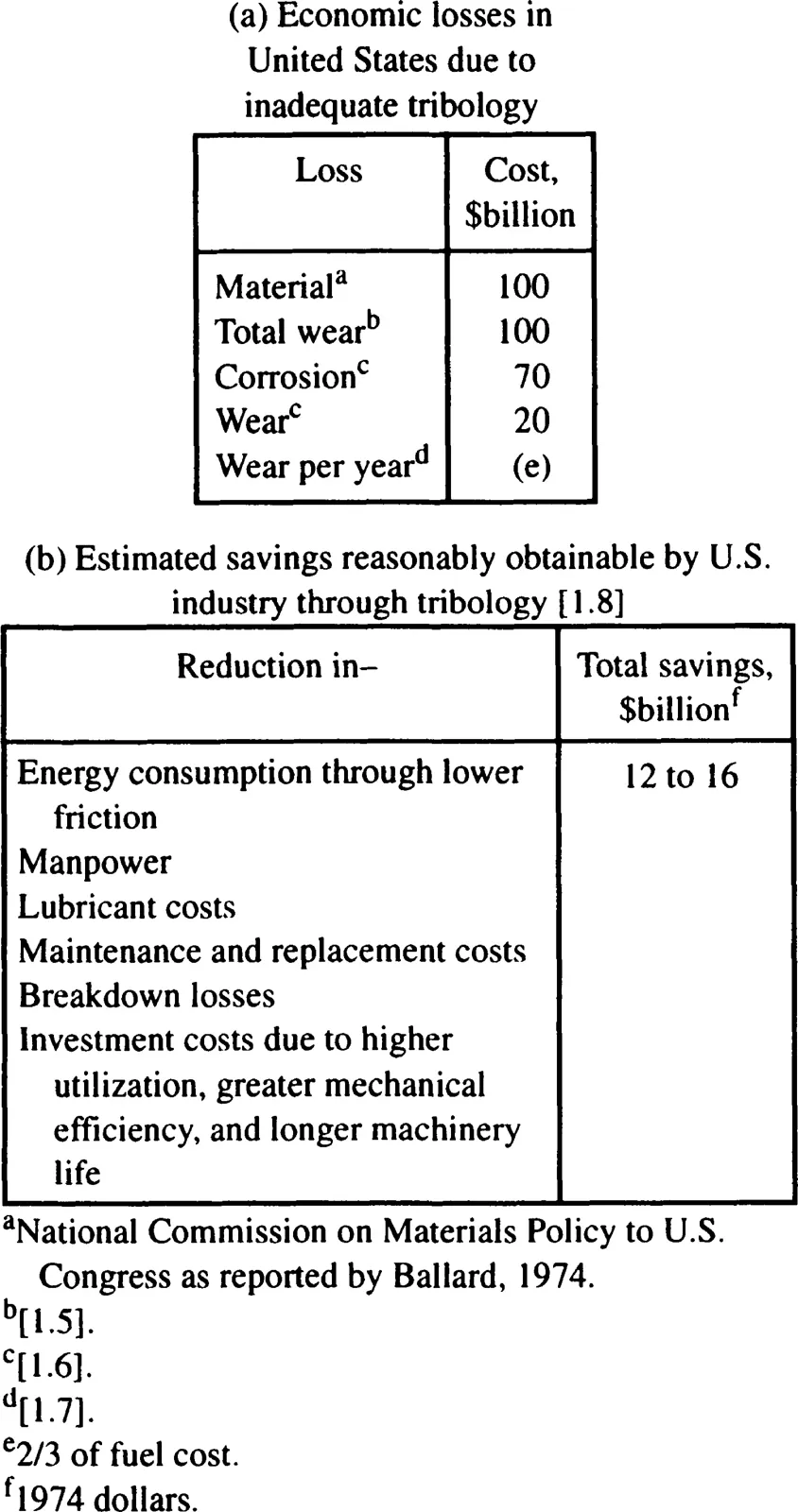

Table 1.2 presents some classical estimates of economic losses due to tribology and savings through tribology. The final report of the National Commission on Materials Policy to the Congress of the United States (as reported by Ballard in 1974) stated that “material losses due to tribology (friction and wear) cost the U.S. economy $100 billion per year, with a material component of this loss of about $20 billion.” At that time Rabinowicz also estimated the total U.S. cost of wear to be $100 billion per year [1.5]. In 1978 the National Bureau of Standards (presently, the National Institute of Standards and Technology) estimated $70 billion for corrosion and $20 billion for wear [1.6]. Peterson estimated that the wear cost for naval aircraft and ships per year is approximately two-thirds the fuel cost [1.7]. These figures indicate that the cost of tribological losses is large and should be reduced by national efforts.

Jost, of the United Kingdom, suggested that with research efforts it is comparatively easy and inexpensive to save up to 20% of tribological losses. For example, for the United States the calculated savings would have been $12 billion to $16 billion per year in 1974 [1.8]. It is not surprising that estimates of financial savings for the United States in 1977 are significantly larger, and range from $16 billion to more than $40 billion per year [1.9, 1.10]. It is now believed that proper attention to tribology, especially in education, research, and application, could lead to economic savings of between 1.3 and 1.6% of the gross national product (GNP) [1.8]. Thus, tribology impacts strongly on the national economy and on the lifestyles of most people. Wear contributes to short product lives and friction contributes to energy consumption. As material and energy shortages develop, there will be greater demand for longer product lives, increased wear resistance, and reduction in energy consumption through lubrication and accordingly lower friction.

TABLE 1.2.—ECONOMIC IMPACTS OF TRIBOLOGY

The most effective way to reduce friction and wear is to separate the two sliding surfaces by means of a lubricating film (third body), such as a film of solid lubricant, oil, grease, or gas. Elements of machines (such as plain or rolling-element bearings, slides, guides, ways, gears, cylinders, flexible couplings, chains, cams and cam followers, and wire ropes) have fitted or formed surfaces that move with respect to each other by sliding, rolling, approaching and receding, or combinations of these motions. Therefore, these elements are lubricated to prevent or reduce the actual contact between surfaces. Moving surfaces of machine elements are lubricated by interposing and maintaining films that minimize actual contact between the surfaces and that shear easily so that the frictional force opposing surface motion is low. If actual contact between surfaces occurs, high frictional forces leading to high temperatures and wear will result.

Without lubrication most machines would run for only a short time. With inadequate lubrication excessive wear is usually the most serious consequence, since a point will be reached, usually after a short period of operation, when the machine elements cannot function and the machine must be taken out of service and repaired. Repair costs (material and labor) may be high, but lost production or lost machine availability may be by far the greatest cost. With inadequate lubrication, even before elements fail, frictional forces between surfaces may be so great that drive motors will be overloaded or frictional power losses will be excessive. Finally, with inadequate lubrication machines will not run smoothly and quietly.

1.3 Historical Perspective of Tribology and Solid Lubricants

Historical factors have influenced the development of tribology, in particular solid lubricants. This brief perspective will help the reader understand the present state of the science and technology in this field. A detailed history of tribology, including lubricants and lubrication, can be found in the literature (e.g., [1.11, 1.12]).

We live in a solid world. The earth itself is solid; the stones and sands on its surface are solid; people and their tools and their machines are solid. These solids are in contact with each other. Whenever two solids touch each other so that forces of action and reaction are brought into play, the solids may be said to undergo a surface interaction [1.13]. Naturally, the history of tribology spans a period similar to that of recorded history. Important tribological developments occurred in prehistoric and early historic times.

The first civilization recorded in the history of humanity developed in the fourth millennium B.C., probably about 3500 B.C., in a territory known as Sumer adjacent to the Persian Gulf at the southern end of Mesopotamia (see the earlier chapters of [1.11]). Somewhat later, Egyptian civilization flourished. Five recorded accomplishments of the Sumerian and Egyptian civilizations (3500 B.C. to 30 B.C.) are of great tribological significance:

1. Drills employing alternating rotary motion and simple bearings were developed for making fire and drilling holes.

2. The potter’s wheel, employing simple pivot bearings made from wood or stone, was produced to facilitate the throwing of clay at relatively high rotational speeds.

3. The wheeled vehicle appeared.

4. Heavy stone statues and building blocks were transported on sledges.

5. Lubricants were used in a number of applications involving rotation and translation.

Lubricants were mainly of vegetable or animal origin. A most interesting story related to the early use of lubricants comes from the building of the pyramids in the third millennium B.C. Hydrated calcium sulphate (gypsum) was used to form the thin bed of viscid mortar. The mortar acted as a lubric...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Preface

- Acknowledgments

- Table of Contents

- Chapter 1 Introduction and Background

- Chapter 2 Characterization of Solid Surfaces

- Chapter 3 Properties of Clean Surfaces: Adhesion, Friction, and Wear

- Chapter 4 Properties of Contaminated Surfaces: Adhesion, Friction, and Wear

- Chapter 5 Abrasion: Plowing and Cutting

- Chapter 6 Friction and Wear Properties of Selected Solid Lubricating Films: Case Studies

- Chapter 7 Aerospace Mechanisms and Tribology Technology: Case Studies

- Chapter 8 Structures and Mechanical Properties of Natural and Synthetic Diamond

- Chapter 9 Chemical-Vapor-Deposited Diamond Film

- Chapter 10 Surface Design and Engineering Toward Wear-Resistant, Self-Lubricating Diamond Films and Coatings

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Solid Lubrication Fundamentals and Applications by Kazuhisa Miyoshi in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.