- 368 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

The Ergonomics Kit for General Industry

About this book

Written by Dan MacLeod, one of the most experienced practitioners in the field, The Ergonomics Kit for General Industry, Second Edition contains everything you need to set up or improve your workplace ergonomics process. MacLeod describes the financial benefits of workplace ergonomics and ways to think about these tools that make good business sens

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access The Ergonomics Kit for General Industry by Dan MacLeod in PDF and/or ePUB format, as well as other popular books in Technologie et ingénierie & Ingénierie industrielle. We have over one million books available in our catalogue for you to explore.

Information

Subtopic

Ingénierie industriellePart I – Why?

Electronic Summary

A summary of Part I, entitled 25 Ways Ergonomics Can Save You Money, is available electronically. This enables you to print it and provide it to managers and supervisors as part of your effort to gain commitment and involvement. See the Table of Contents.

Chapter 1

Good Ergonomics is Good Economics

The following story is an excellent illustration of the business value of the workplace ergonomics process. The bottom line is that an employee, after attending a class in ergonomics, came up an idea that was cost-free, eliminated a painful activity, and yielded 90% reduction in time needed to complete the job.

Vehicle mechanic

The company was a distribution operation with a large truck repair facility. Every year, some of the older delivery vans were cleaned up, repaired, and sold. The job involved removing the decals that covered much of the surface of the vans. The procedure — “The way we’ve always done it” — was to take a small razor blade tool and start scraping. Normally it would take a day or two to scrape a whole van. The task was unpopular and was traditionally assigned to the person with the lowest seniority.

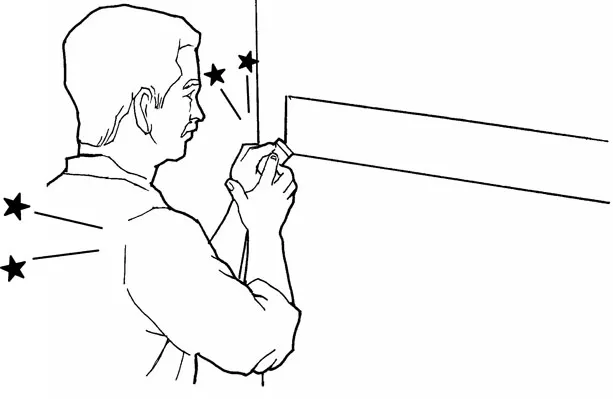

Before – Scraping the decals with a razor tool.

Painful shoulder

One morning, an employee was told to start scraping off the decals from a series of vans. By noon, his shoulder and hand were aching. By quitting time, he had almost completed one van and he was in pain. He looked at the work order and he discovered that he had 19 more vans to clean — he was going to be scraping all month.

Then he remembered our class: “The ergonomics guy said if we had a problem we should tell someone.” So he sought out the Safety Committee Chairman, who happened to be the union steward for the facility and someone who I had worked with previously on other issues.

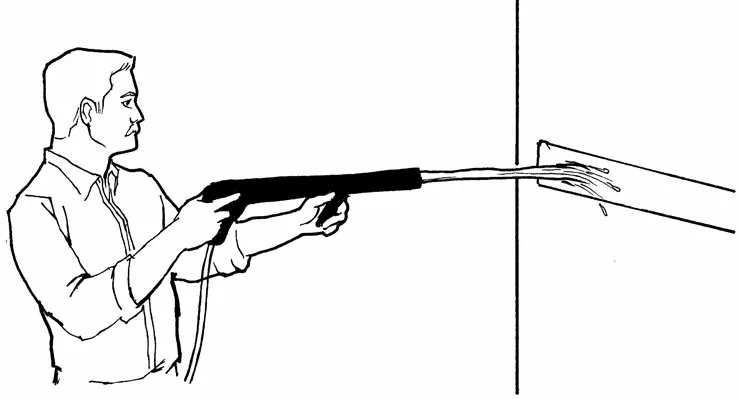

The Safety Committee Chairman, well familiar with the task, said, “Well, the ergonomics guy said that the most important thing to do is think.” So the two walked to the scraping area and started brainstorming. After a time, one suggested using the power wash (that they normally used to clean the truck) to soak the decal and maybe to loosen it. They discovered that the hot water heated up the aluminum skin of the van and made it easier to remove the decals. So they turned up the heat of the water, played it on the van for a few minutes, then were astonished to find that the decals easily peeled off.

Brainstorming

The time needed to remove the decals fell from one or two days per van to one or two hours. The solution was free, since the power wash was already on hand.

After – The power wash heats the surface of the van.

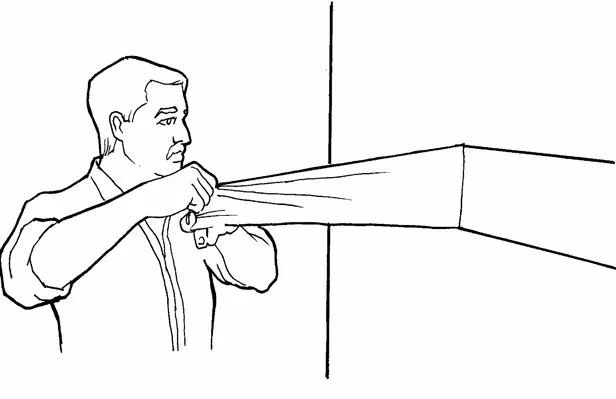

The decals peel off.

Thinking is good

In my view, this story represents the ideal of ergonomics success stories: it solved a problem that was hurting people; it resulted in dramatically greater efficiency; the employees themselves came up with the idea; and it was free. All that was needed establishing a workplace process that got people in the habit of challenging “the way we’ve always done it.”

How to Understand Ergonomics in a Way That Makes Good Business Sense

Many people have gotten the false impression that ergonomics is a burden on business. Part of the explanation is historical — ergonomics gained visibility in much of business and industry because of regulation and litigation. The first exposure that many managers had to the field was media accounts of the multimillion dollar fines levied by OSHA against companies for problems related to poor ergonomics.

The reality is that ergonomics is good for business. To be sure, no claim is made here that all problems have an ergonomics solution or that in every instance the benefits will pay for the costs. Ergonomics is a problem-solving tool, one among many that organizations have. And like every other tool, it has its applications and its shortcomings. But in the main, concepts of ergonomics can help you save money.

Fresh insights with ergonomics glasses

One of the greatest values of ergonomics is that it can cause people to think and thus promote innovation. We can put on our “ergonomic glasses” and view the workplace and end-products from a new perspective. We begin to ask questions about how a tool or production process ought to be designed to make it more human-compatible. Ultimately, that thought process can stimulate fresh insights on old problems. Ergonomics can be a tremendous source of innovation.

Through our ergonomic glasses, we can spot problems that we have overlooked before. We can challenge assumptions, find new ways to accomplish our goals, and sometimes find tasks that simply do not need to be done anymore.

Involving the user

Creativity occurs when end-users and designers interact, which is part of the ergonomics process. In the workplace, this interaction can involve team efforts between managers, engineers, and employees. For development of products and services, it can mean involving customers in ergonomic studies that aid in design. In each case, we can gain insights into products and production as we tap each source of ideas, learn from each other, and spark new thoughts.

40,000 years of ergonomic progress

Another perspective that can help us think about ergonomics in a way that makes good business sense is to realize that in many ways humans have been using ergonomics for roughly 40,000 years. In the same way that a chemist can view much of the world as chemistry, we can see human advancement as ergonomics. In this sense, ergonomics has existed ever since the first human picked up a stone to use as a tool, capitalizing on a human capability and overcoming a human weakness. Adapting our surroundings to fit us is indeed one of the defining characteristics of our species.

Great Ergonomic Improvements in History

Improvement | Ergonomic Benefit | |

|---|---|---|

Stone ax | Greater strength | |

Wheel | Reduced exertion | |

Chair | Improved posture; reduced static load | |

Power sources: water wheel, steam, electricity | Reduced exertion and repetitive tasks | |

Computer | Reduced repetitive tasks | |

Sliced bread | Reduced motions |

Closer to our own daily lives, we’ve all had experience with ergonomics, even if we have never used the word. We tend to arrange things to fit our own convenience, at least when we can. We keep things we need within easy reach, we change our posture when we are tired of being in the same position, we shift to avoid glare. We try to modify our surroundings to make things easier for us.

So, in some ways, ergonomics is nothing new. By definition, anything that improves (or has ever improved) the interface between humans and systems is ergonomics. Humans have always tried to find better ways of working, taking advantage of our talents and using tools and machines to overcome our limitations. So, from this perspective, it should not be news that ergonomics can promote progress and productivity. As stated above, as a species, we’ve been doing this for quite some time.

Systematic process

The point is that ergonomics is not necessarily anything esoteric or extravagant. On the contrary, much of our economic and technological development has been “ergonomics.”

What is new, however, is the scientific approach to understanding human anatomy and physiology and then methodically designing for people. What now lies before us is to take this natural tendency and turn it into a conscious approach to management and a systematic process for design.

Design failures

Altho ergonomics is in many ways a human tendency, we don’t always do things the right way. A special problem is that many times the designers (and here we include anyone who has set up a task or built a piece of equipment) are not the users, so they may not know the unintended consequences of their plans.

All too often, we plan workplaces based on “efficient movement of product” or “best locations for machines,” all without much thought to how people are supposed to fit in. Too often, we devise products based on the cheapest way to manufacture, or perhaps on aesthetics, but without much regard for the end user. We think we are paying attention to the bottom line, but we may be missing important costs, such as injuries, errors, and inefficient motions.

Although designers often think about how to fit the task to the person, clearly at other times they — that is, we — do not. Consequently, a formal ergonomics process is essential for business.

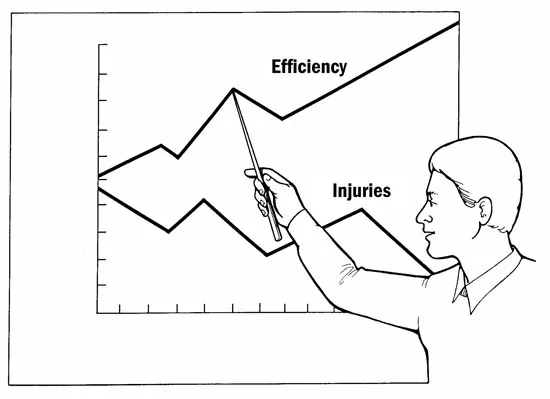

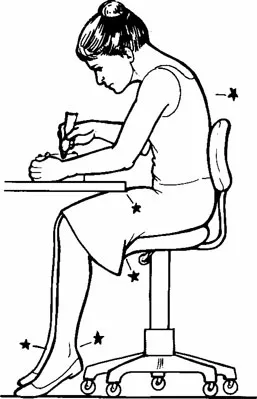

Poor ergonomics can cause discomfort and injury to employees, plus be inefficient.

Hidden costs

Too often we expect people to adapt themselves to fit into whatever arrangement has been devised, believing that it has no associated cost. Unfortunately, the human body cannot adapt to everything. People have differences and they have limitat...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Dedication

- Preface

- Acknowledgments

- About the Author

- Table of Contents

- Introduction

- Part I – Why?

- Part II – How?

- Part III – Practical Tools

- Index