- 295 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Total Quality Management for Project Management

About this book

Finding ways to improve margins can be the difference between organizations that thrive and those that simply survive during times of economic uncertainty. Describing why cost reductions can be just as powerful as increases in revenue, Total Quality Management for Project Management explains how to integrate time-tested project management tools wit

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Total Quality Management for Project Management by Kim H. Pries,Jon M. Quigley in PDF and/or ePUB format, as well as other popular books in Business & Project Management. We have over one million books available in our catalogue for you to explore.

Information

CHAPTER 1 – INTRODUCTION

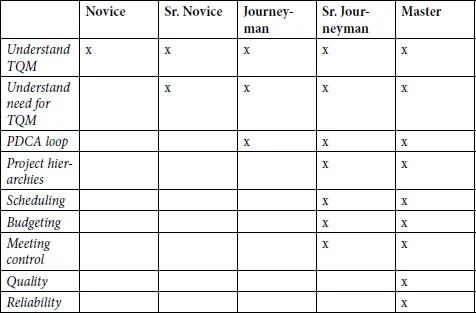

I. Rubric

II. Questions to Ponder

• Does TQM applied to project management (PM) provide any added value?

• Is TQM too abstract or is it really down-to-earth?

• Why is the standard flailing and floundering approach so seductive?

• Does the enterprise really need TQM in project management?

• If our organization transforms itself such that it achieves a higher level of performance, have we really accomplished anything?

• Does TQM/PM have any marketing value?

• Why are there so many quality tools and why are they little used by PMs?

• Why are the quality models different and yet the same (compare and contrast)?

• Isn’t TQM just another way to make somebody some money?

• Is there an ISO version? Isn’t ISO-9000 largely discredited?

• Why can’t we just “roll our own” approach to process improvement?

• Are processes loose guidelines or should we use a disciplined approach?

• Does your organization systematically critique development and project processes to learn how those processes really work and to shorten and improve the processes and products?

III. Why TQM Is Important to the Project Manager

Total Quality Management (TQM) involves the application of quality techniques to all segments of the enterprise. We are recommending that TQM be applied to project management also.

Most of the project managers (PMs) we have known have focused first and foremost on the project schedule, next on the project budget, and lastly on the project quality issues. We suspect this approach may even be so topsy-turvy as to be backwards. At no point have we seen project managers applying any sensible quality techniques to their own process. Ultimately, each project we witnessed devolved into a weekly nagging meeting that lasted at least an hour as the PM desperately tried to assert some level of debatable control by doing a futile “time line review.” We know that powerful methods exist to eliminate the flailing usually seen, particularly at the end of the project.

Figure 1.1 The butterfly effect from chaos theory suggests small causes can have large effects.

This project flailing my be visible at the end of the project; however, the reasons for the flailing are well before this point, usually in the planning phase (see Figure 1.1). The TQM tools demonstrated in the following chapters will show how planning that does not derive from past experience is really not planning at all, but going through the motions. TQM and developing a learning organization are tied together.

IV. TQM Project Manager Scenario

A. Situation

The project manager (PM) created a standard project schedule using Microsoft Project. This individual did not use the tool for budgeting and derived no project metrics (which are available readily in this tool). The PM did not understand resource allocation and the need to inspect the truth-value of statements from supporting departments. Product launch was soon to arrive and insufficient material was available to manufacture a sustainable stream of product. The purchasing activity was in the midst of switching over from MRO (maintenance, repair, and operations) buying where lot sizes are any size—to MRP (manufacturing resource planning) buying, where materials are purchased in bulk lots to ensure an economic order quantity. The enterprise was in danger of shutting down the customer.

B. Objective

Bring materials acquisition and release back to sanity.

C. Action

The initial action was to allow MRO buying as well as MRP purchasing. A company director indicated that “this is World War II and I want to see piles of the correct materials” as an alternative to misguided interference from a lean manufacturing initiative. This director also recommended that the materials handling people “kit” the material. “Kitting” occurs when the materials staff counts the required components for a build of X parts and puts everything in a kit. It is short of lean manufacturing, but it ensures the correct parts are available, although it does present the risk of shutting down the line if a part is missing (which would happen anyway).

D. Results

Production was brought back into a sane sequence. The PM was encouraged to inspect the stockroom to visually verify that the correct parts were available.

E. Aftermath

Sadly, this approach worked so well it was never used again. The enterprise continued to ignore the MRO/MRP discontinuity for all future projects. This painful lesson was not learned.

V. Total Quality Management Prerequisites

Before we can even begin to discuss total quality management for project managers the organization must fulfill some prerequisites. Some of these include the following:

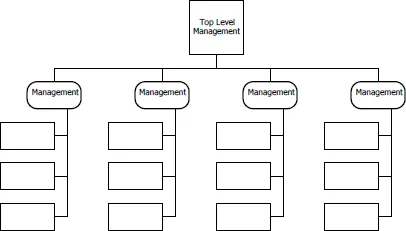

• A reasonably well-established hierarchy (see Figure 1.1)

• A set of documented processes

• Individuals willing to champion the new initiative

• Management support for the new initiative

• An understanding of the benefits of total quality management

• A corporate culture that does not game the system

We’re going to look at total quality management from two perspectives, that of total quality management on project management and that of project management on total quality management. Out of this dialectical relationship arises something better than either item by itself. It may seem a trifle odd, but most organizations do not apply their quality practices to the project management process. One would think that the launch of the new product for the creation of a new service would be sufficient to drive quality practices into project management. In our experience, this outcome is just simply not the case.

Figure 1.2 Example of a well-defined organization hierarchy.

Consider organizations that routinely develop a set of products or services. These companies have a set of processes and are structured in such a way to deliver these products to the consumer. We will call a hypothetical version of such a company a project factory for lack of a better name. Each stage or functional area (example systems engineering, embedded engineering, and verification) will have a set of activities that are performed using some set of defined processes. The same is true for the project management discipline. In the end, we want to show how these tools can be applied to these areas to continually understand how your organization works, and more importantly, how to continually improve that performance.

Some readers may feel that total quality management is passé in the age of Six Sigma quality and manufacturing Lean practices. Each approach has its place. Our take on the situation is as follows:

• Six Sigma is the obvious choice for cost reductions and other cost-cutting activities

• Lean is the primary tool used for waste reduction

• Lean Six Sigma is a conflation of the Six Sigma algorithm and hard-money approach with Lean objectives

• TQM is the approach of choice when an organization or a part of an organization desires to perform a total overhaul of the complete system

In most cases, Six Sigma is not applied to an organization as a systemic approach to effect organizational transformation, but rather, the approach is used to look for cost reduction opportunities that can improve the bottom line. When not afflicted with hucksterism, the Lean approach can be used to save more money, improve production flow, and improve the bottom line. The same applies to Lean Six Sigma. Unfortunately, the lack of a systemic approach doesn’t always move these worthy methodologies in the direction of maximizing customer satisfaction. In short, we suggest that TQM is relevant when thoughtfully applied and we feel that the approach is particularly relevant when dealing with the frequent nightmare that pertains to project management, especially with regard to scheduling and budgeting—not to mention the quality of the product or service. In the end it is the project manager who must balance the competing demands from the project organization as well as other stakeholders in the project.

Project management activities produce metrics just as the line organization does. If an organization has aspirations of being a project factory, for example, these same tools would be required as they would in a manufacturing environment. Specifically the tools used in total quality management are applied to the manufacturing discipline. In our project factory world, the line organization would be the various stations in the production process.

While all projects by definition are unique, we can find considerable routine within that uniqueness. Consider, for example, an organization that produces embedded products for a vehicle. For any given organization or industry, there are certain steps often considered to be a prudent approach to the work. For our embedded automotive company we may always start with generating a set of concepts and then a critique of those concepts to improve the product before we start putting hardware together. In this way, the concept generation activity, for example, could be considered a step in the manufacturing process of the project. Taking the perspective that this is a manufacturing station, we can apply the TQM tools to understand the capability and variation in the production processes via the specific activity at that station. While this explicitly speaks to the line organization, it need not be limited to that. By extension, these tools can be applied to any of the developmental processes as well as the data that falls in the area of project management.

VI. Organizational Attributes

Any organization that chooses to pursue an application of total quality management to project management and, in some cases, program management must possess certain attributes. Some of these attributes are as follows:

• Training in total quality management (or Six Sigma)

• Enough structuring to support project management (in other words, we are not dealing with a fly-by-night entrepreneurial experimentation)

• Clearly defined roles

• Defining processes

• Willing to adhere to those processes

We have been surprised during our careers when we discover that some companies don’t understand the flow of material, services, and information from suppliers into the enterprise process and out to their customers. These flows should be well-documented. If we are discussing an ISO 9001 company, then we know many of the processes will be documented because it is part of the requirements for ISO-9000 certification. With regard to the accounting and fiducial governance function in North America, the Sarbanes-Oxley regulatory requirements will drive a significant level of process documentation. Why are we focusing on process documentation? Documented processes make it easier to measure baseline activities to determine if our interventions have produced salutary result...

Table of contents

- Cover

- Title Page

- Copyright

- Contents

- LIST OF FIGURES

- CHAPTER 1 – INTRODUCTION

- CHAPTER 2 – METRICS AND REQUIREMENTS

- CHAPTER 3 – TQM TOOLS

- CHAPTER 4 – PROJECT MANAGEMENT TOOLS

- CHAPTER 5 – STATISTICS AND CONTROL

- CHAPTER 6 – PROCESS ANALYSIS AND IMPROVEMENT

- CHAPTER 7 – PROCESS CONTROL AND METRICS

- CHAPTER 8 – INSPECTION AND QUALITY ASSURANCE

- CHAPTER 9 – TRACKING METRICS

- CHAPTER 10 – OTHER SUPPORTING INITIATIVES

- APPENDIX 1 – CHANGE MANAGEMENT

- APPENDIX 2 – TEMP EXAMPLE

- APPENDIX 3 – TIEMPO

- APPENDIX 4 – PRODUCT VERIFICATION

- INDEX