- 312 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Industrial Hygiene Evaluation Methods

About this book

Professionals and students in the field of industrial hygiene need a concise guide that thoroughly covers the practical methods of evaluating health threats in the workplace.

Bisesi and Kohn's Industrial Hygiene Evaluation Methods, Second Edition introduces basic methods for evaluating work and some non-work environments in order to detect and measure physical, chemical and biological agents, as well as hazardous ergonomic factors. The book is divided into relatively short units that provide concise overviews and descriptions of basic concepts. Each unit is followed by practical technical exercises. These exercises foster the understanding of basic industrial hygiene principles and practices for collection, detection, identification, calculation, and interpretation of qualitative and quantitative data. Exercises can be conducted in a setting in which agents and other factors are detectable and measurable. Alternatively, the simulated evaluation exercises that are included can be conducted in a classroom or laboratory.

This book is an introductory reference for environmental and occupational health and safety students and practitioners. It is an indispensable tool that illustrates methods fundamental to industrial hygiene practice, and is just as valuable in the professional's office as it is in the classroom.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

UNIT 1

Evaluation of Hazardous Agents and Factors in Occupational and Nonoccupational Environments

LEARNING OBJECTIVES

At the completion of Unit 1, including sufficient reading and studying of this and related reference material, learners will be able to correctly:

- Summarize the roles of occupational health specialists/industrial hygienists.

- Name and define the categories of industrial hygiene sampling and analysis for determination of external exposure to physical, chemical, and biological agents.

- Discuss the aspect of evaluating ergonomic factors.

- Discuss the aspect of evaluating hazard controls.

- Discuss the industrial hygiene and medical monitoring and analysis relative to external, internal, and effective exposures.

OVERVIEW

The occupational environment can be simply defined as any place, indoors or outdoors, where people work in return for financial or other remuneration. The profession of occupational health, or industrial hygiene, is based on the tetrad of anticipation, recognition, evaluation, and control of agents, factors, and stressors related to the occupational environment that may adversely affect the health of workers and other members of the community. All four aspects of the tetrad are interrelated. The content of this book, however, will mostly emphasize some major instrumentation, methods, and practices of industrial hygiene evaluation.

The occupational environment is evaluated by occupational health specialists, historically and presently, most commonly referred to as industrial hygienists. Industrial hygienists are involved with evaluation of the occupational environment from several different perspectives. Industrial hygiene evaluation activities include conducting walk-through surveys of facilities and applicable monitoring activities to gather both qualitative and quantitative data. Monitoring activities include sampling and analysis to collect, detect, identify, and measure hazardous physical, chemical, and biological agents present in specific areas and to which workers and others are potentially or actually exposed. Industrial hygienists commonly interact directly or indirectly with clinical professionals, such as physicians, nurses, and audiologists. Industrial hygienists are often familiar with some general principles of clinical techniques to evaluate workers to determine if they reveal signs of adverse impact from excessive exposure to agents, such as hearing loss due to prolonged exposure to elevated sound levels. In addition, industrial hygienists evaluate control measures, including work practices, personal protective equipment, and ventilation systems, to determine if they effectively reduce the potential for worker exposure. Industrial hygienists also may be involved with evaluation of ergonomic factors to determine if there is an appropriate match or fit between workers and their physical workplace environments.

Industrial hygiene principles and practices often extend beyond the occupational and manufacturing settings. For example, professional- and technician-level industrial hygienists are frequently involved in indoor air quality (IAQ) investigations in nonoccupational settings, such as homes, schools, and other nonmanufacturing settings. Accordingly, many of the topics presented in this book are applicable to both occupational and nonoccupational and manufacturing and nonmanufacturing environments.

EVALUATION OF EXTERNAL EXPOSURE VIA INDUSTRIAL HYGIENE MONITORING

Sampling and analysis refer to the representative collection, detection, identification, and measurement of agents found in environmental matrices such as air, water, and soil. In occupational and nonoccupational environments, both indoors and outdoors, air is sampled (collected) to detect and identify physical, chemical, and biological agents and to measure related levels. The most common matrix that is sampled and analyzed in the occupational environment is the air. Indeed, inhalation of contaminated air by workers is considered the major mode of foreign agent entry in most occupational environments. In addition, the air serves as a matrix for elevated sound levels, extremes of temperature and humidity, and transfer of ionizing and nonionizing radiation energies.

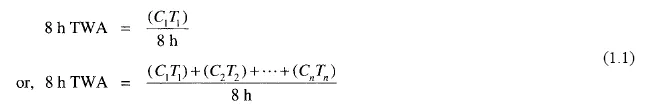

The data collected and analyzed are used to evaluate both actual and potential external exposures to agents encountered by humans. In turn, the levels are compared to established occupational exposure limits (OELs) to determine if acceptable values for exposure have been exceeded. In the U.S., regulatory permissible exposure limits (PELs) are enforced by the Occupational Safety and Health Administration (OSHA) for nonmining operations and processes. Regulatory exposure limits for the mining industry are the threshold limit values (TLVs) enforced by the Mine Safety and Health Administration (MSHA). Other agencies have established occupational exposure limits as guidelines, most notably the TLVs by the American Conference of Governmental Industrial Hygienists (ACGIH) and Recommended Exposure Levels (RELs) by the National Institute for Occupational Safety and Health (NIOSH). In some cases, a parameter will be monitored without concern necessarily for excessive exposure. For example, illumination is evaluated and compared to recommend guidelines to assure that there is an appropriate, neither inadequate nor excessive, quantity of lighting. Refer to Appendix A for a summary of some related strategies for exposure assessment and calculations of time-weighted averages (TWAs) for comparisons to established regulatory and nonregulatory occupational exposure limits. In relation, Appendix B is an example of an outline format of an industrial hygiene evaluation report showing information that must be considered, documented, and reported.

Sampling and related analytical activities are divided into several categories to reflect the type of monitoring that is conducted. Categories are based on factors that include time, location, and methods of collection (sampling) and detection, identification, and measurement (analysis). Each serves a purpose in evaluating the occupational environment to determine the degree of workers’ external exposure to various agents.

(i)

Instantaneous or Real-Time Sampling

Instantaneous sampling refers to the collection of a sample for a relatively short period ranging from seconds to typically less than 10 min. A major advantage of instantaneous sampling is that both sample collection and analysis are provided immediately via direct readout from the sampling device. The data represent the level of an agent at the specific time of sampling. Accordingly, instantaneous sampling is also referred to as direct reading and real-time sampling. Real-time sampling is perhaps a more appropriate designation since there are some devices already developed and being designed for integrated or continuous monitoring (see Section ii) that provide a direct-readout or instantaneous result without need for laboratory analysis and the associated delays. In addition, the main purpose of real-time sampling is to reveal what a level of an agent is, at an immediate point of time or during real-time.

The application of real-time sampling varies. The strategy is used when preliminary information regarding the level of an agent is needed at a specific time and location. For example, real-time sampling is commonly used for screening to identify agents and measure related levels. This is important for developing follow-up monitoring strategy and determining if integrated sampling is warranted. Real-time sampling is also beneficial for determining levels of agents during short-term operations or specific isolated processes when peak levels are anticipated or suspected.

(ii)

Integrated or Continuous Sampling

Integrated sampling refers to the collection of a sample continuously over a prolonged period ranging from more than 10 or 15 min to typically several hours. Integrated sampling is also referred to as continuous monitoring reflective of the extended period of sample collection. Most work shifts are 8 h and occupational exposure limits are most commonly based on an 8-h exposure period. Accordingly, it is very common as well for sampling to cover the duration of the shift. Several strategies can be followed. For example, a sample run could be started immediately at the beginning of the 8-h shift and allowed to run until the shift ends. Analysis of the sample would provide a single value representative of the level of a particular agent during the shift. The single value represents an integration of all the levels during the shift. The single value, however, does not provide information regarding fluctuations of levels that were higher, lower, or not detectable during shorter periods within the 8-h shift. In addition, there is no indication as to the levels at specific times and locations during the shift. As a result, an alternative strategy could involve collection of several samples of shorter duration during the entire shift. In turn, analysis of the individual samples provides levels associated with specific times, tasks, and locations during the 8-hour shift. Concentration (C) and corresponding sample time (T) data from one sample (C1) or several individual samples (C1 to Cn) can be time-weighted (C × T) and averaged, by dividing by a specific time period (e.g., 8 h), to provide a single overall TWA for the 8-h shift (Appendix A).

A major advantage of integrated sampling is that it provides a single value for the level of an agent over a prolonged period. The level of an agent can be determined during discrete times and locations within a workshift to assist in identifying factors that influence elevated values of exposure or external exposure. A major disadvantage associated with integrated sampling is that in most cases, samples must be submitted to a laboratory for analysis prior to knowing what has been detected in the related measurements. This frequently results in a delay between sample collection and data reporting.

Several fundamental procedures must be followed when conducting integrated personal and area sampling. It is important to assure that monitoring devices and/or sampling trains are properly assembled, calibrated, and operated for the specific monitoring activity. It is equally important to assure that field monitoring data are recorded so that samples can be associated with specific locations, areas, individuals, dates, times, processes, equipment, temperatures, humidity, atmospheric pressure, and so on. Figure 1.1 summarizes a representative example of a generic integrated monitoring protocol.

- Make sure that all active monitoring devices are pre-calibrated and order checked for accurate calibration. Check batteries for charge. In addition, confirm that sampling media are not expired.

- Select a worker or area to be monitored. Briefly explain the purpose of monitoring to the worker and/or workers in the area. Advise individuals not to tamper with the instrument or medium. Record the worker's name or the area sampled, worker's social security number, and job title. Record date, sampling location and sampling device and/or media identification number.

- If a personal sample, attach the monitoring device and/or medium to the worker and make sure that they do not interfere with the worker's activities. Attach the sampling medium (e.g., filter cassette) at the worker's clavicle near the collar if a breathing zone sample is needed. If a hearing zone sample is needed, attach the medium (e.g., audiodosimeter microphone) at the trapezius or the ear. If a flexible hose or a cord is involved, allow enough slack to accommodate worker's range of motion when standing, sitting, bending, and twisting and secure any excess so that it does not serve as a potential interference or hazard.

- For an area sample, position the monitoring device and/or medium approximately 4 to 6 feet from the floor. Make sure that the medium is not in direct contact with or too close to a contaminant (e.g. settled or spilled particulate)

- Turn "ON" an active monitoring device and record "start time". Make sure that the device is operating. If a passive device is used, record "start time" when it is first exposed to the workplace atmosphere.

- Document the worker's performed tasks and/or processes operating in the area during the monitoring period. Note times when exposure may be high due to specific activities or process phases. Check the monitoring device and medium after the first 15 minutes to half an hour, and at least two-hour intervals thereafter. If applicable, change the medium when conditions warrant (e.g., signs of overloading; excessive airborne concentrations of contaminant; to isolate exposure to specific time periods or specific tasks).

- Record the "stop time" when medium is changed (or sampling is concluded) and "start time" when medium is replaced; make sure that the identification number of each sample is recorded. If applicable, handle field blanks in a similar manner as samples (recording start and stop times in military time makes it easier to determine sample time and convert to minutes).

- Remove monitoring device and/or media from the worker or the area being sampled.

- Make sure that all active monitoring devices are post-calibrated or checked for accurate calibration. Post-calibration should be conducted prior to recharging batteries.

Figure 1.1 Example of a protocol for personal and area integrated air sampling.

(iii)

Personal Sampling

Personal sampling involves direct connection of an integrated monitoring device to a worker. The device, in turn, will collect a sample or record the intensity of an agent in the specific areas and during specific tasks conducted by a worker. Indeed, personal sampling is frequently a form of mobile monitoring since the sampling device travels to the same areas and at the same times as the worker that wears it.

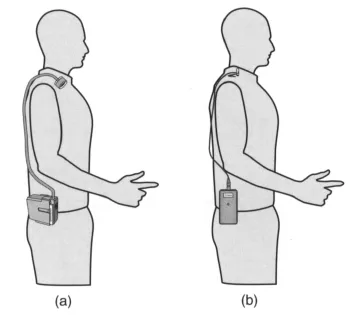

If inhalation is the mode and the respiratory system the route of entry of an agent, the sampling device or related sampling medium is positioned in the worker’s breathing zone. The breathing zone refers to an area within a 9- to 12-in. distance (radius) from the worker’s nose and mouth (Figure 1.2a). Typically, an integrated monitoring device for personal sampling is attached near the worker’s clavicle (collar bone). Relative to evaluation and impact of sound levels, however, hearing is the major mode and the auditory system is the route of entry. When conducting personal monitoring for sound, therefore, the sampling device can be connected to the worker’s hearing zone. This zone is ideally the ear itself, or the trapezius region of the shoulder—a region within a 9- to 12- in. distance from the ear (Figure 1.2b).

Instantaneous or real-time monitors also can be used to determine levels of agents in a worker’s breathing and hearing zones. For example, a sound level meter can be held by the individualconducting the monitoring in the auditory region of a worker. This would provide an instantaneous assessment of sound levels in the worker’s hearing zone at the specific time of monitoring.

Figure 1.2 (a) Active-flow pump is positioned at the worker’s waist. Flexible tubing connects the pump to a sample collection medium clipped to the worker’s shirt along the collar bone and positioned within his breathing zone to collect a personal integrated sample. (b) Sound (noise) dosimeter is positioned at the worker’s waist. Flexible wire connects the dosimeter to a microphone clipped to the worker’s shirt along the trapezius and positioned within his hearing zone to collect a personal integrated sample.

(iv)

Area Sampling

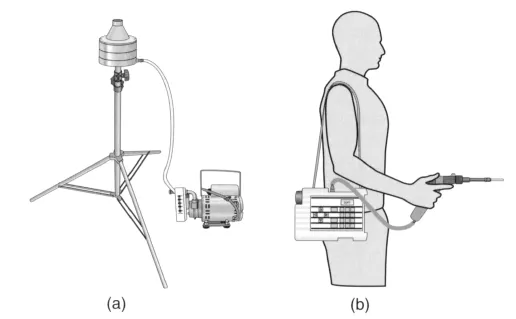

The focus of area sampling is to evaluate the levels of agents in a specific location, instead of evaluating levels encountered by a specific worker. Area integrated monitoring devices are typically positioned in a stationary location (Figure 1.3a). Stationary area integrated samples are often collected at a height of approximately 4 ft from the floor or ground. The data from a stationary area integrated sample represent the level of an agent in the specific area during the sampling period. Area instantaneous or real-time monitoring, however, involves area sampling in either a stationary or mobile mode. Stationary area instantaneous monitoring may be conducted while positioning or holding and operating a direct read instrument and standing still in a given location. Alternatively, an instantaneous monitoring instrument can be transported via carrying it or rolling it on a cart to various locations while intermittently checking the indicator or readout on the instrument (Figure 1.3b).

(v)

Active Flow Sampling

Presently, most monitoring techniques for actual collection of an air sample or contaminant from the air involve active flow methods. Active flow sampling implies that energy, such as an electronically powered (either AC or DC) device, is required to collect the sample. Air and airborne contaminants are actively pulled through a collection medium or into a collection container. For example, battery-powered air sampling pumps are frequently used to pull air through sample collection media or into a sample container. Energy also can be generated manually, via physically pumping a device for example, to conduct active flow sampling.

Figure 1.3 (a) Two-stage bioaerosol impactor is positioned on a stationary tripod. Flexible tubing ...

Table of contents

- Cover Page

- Title Page

- Copyright Page

- Preface

- Acknowledgments

- About the Author

- UNIT 1: Evaluation of Hazardous Agents and Factors in Occupational and Nonoccupational Environments

- UNIT 2: Hazardous Environmental Agents and Factors

- UNIT 3: Sampling and Analytical Instruments Used to Evaluate the Occupational Environment: Generic Descriptions and Some Related Aspects of Calibration

- UNIT 4: Evaluation of Airborne Total Particulate: Integrated Personal and Area Monitoring Using an Air Sampling Pump with a Polyvinyl Chloride Filter Medium

- UNIT 5: Evaluation of Airborne Respirable Particulate: Integrated Personal and Area Monitoring Using an Air Sampling Pump with a Polyvinyl Chloride Filter Medium and Dorr-Oliver Cyclone

- UNIT 6: Evaluation of Airborne Fibers as Asbestos: Integrated Personal and Area Monitoring Using an Air Sampling Pump with a Mixed Cellulose Ester Filter Medium

- UNIT 7: Evaluation of Airborne Metal Dusts and Fumes: Integrated Personal and Area Monitoring Using an Air Sampling Pump with Mixed Cellulose Ester Filter Medium

- UNIT 8: Evaluation of Airborne Particulate: Instantaneous Area Sampling Using a Direct-Reading Aerosol Meter

- UNIT 9: Evaluation of Airborne Organic Gases and Vapors: Integrated Personal and Area Monitoring Using an Air Sampling Pump with a Solid Adsorbent Medium

- UNIT 10: Evaluation of Airborne Inorganic and Organic Gases, Vapors, and Mists: Integrated Personal and Area Monitoring Using an Air Sampling Pump with a Liquid Absorbent Medium

- UNIT 11: Evaluation of Airborne Combustible and Oxygen Gases: Instantaneous Area Monitoring Using a Combined Combustible and Oxygen Gas Meter

- UNIT 12: Evaluation of Airborne Inorganic and Organic Gases and Vapors: Instantaneous Area Monitoring Using a Piston or Bellows Air Sampling Pump with a Solid Sorbent Detector Tube Medium

- UNIT 13: Evaluation of Airborne Toxic Gases and Vapors: Instantaneous Area Monitoring Using Organic Gas and Vapor Meters

- UNIT 14: Evaluation of Surface and Source Contaminants: Monitoring Using Wipe and Bulk Sample Techniques

- UNIT 15: Evaluation of Airborne Bioaerosols: Integrated Area Monitoring Using an Air Sampling Pump with an Impactor and Nutrient Agar Medium

- UNIT 16: Evaluation of Airborne Sound Levels: Instantaneous Area Monitoring Using a Sound Level Meter and an Octave Band Analyzer

- UNIT 17: Evaluation of Airborne Sound Levels: Integrated Personal Monitoring Using an Audio Dosimeter

- UNIT 18: Evaluation of Personal Hearing Thresholds: Instantaneous Personal Monitoring Using an Audiometer

- UNIT 19: Evaluation of Heat Stress: Instantaneous Area Monitoring Using a Wet-Bulb Globe Temperature Assembly and Meter

- UNIT 20: Evaluation of Illumination: Instantaneous Area Monitoring Using a Light Meter

- UNIT 21: Evaluation of Airborne Microwave Radiation: Instantaneous Monitoring Using a Microwave Meter

- UNIT 22: Evaluation of Airborne Extremely Low Frequency Electromagnetic Fields: Instantaneous Area Monitoring Using a Combined Electric and Magnetic Fields Meter

- UNIT 23: Evaluation of Airborne Ionizing Radiation: Instantaneous Area Monitoring Using an Ionizing Radiation Meter

- UNIT 24: Evaluation of Ergonomic Factors: Conducting Anthropometric and Workstation Measurements

- UNIT 25: Evaluation of Air Pressure, Velocity, and Flow Rate: Instantaneous Monitoring of a Ventilation System Using a Pitot Tube with Manometer and a Velometer

- UNIT 26: Evaluation of Personal Protective Equipment: Selection, Maintenance, and Fit of Dermal and Respiratory Protective Devices

- UNIT 27: Evaluation of Personal Pulmonary Function: Instantaneous Monitoring Using an Integrated Electronic Spirometer

- APPENDIX A: Industrial Hygiene Sampling Strategies, Calculations of Time- Weighted Averages, and Statistical Analysis

- APPENDIX B: Example: Outlined Format of an Industrial Hygiene Evaluation Report

- APPENDIX C: Answers to Case Studies for Units 4, 5, 6, 7, and 9 and Problem Sets in Appendix A

- Bibliography and Recommended References

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Industrial Hygiene Evaluation Methods by Michael S. Bisesi in PDF and/or ePUB format, as well as other popular books in Tecnología e ingeniería & Ciencia medioambiental. We have over one million books available in our catalogue for you to explore.