![]()

1

INTRODUCTION

This book deals with ancient (inorganic) materials in a range of ways. In writing this book my aim was to relate as closely as possible scientific aspects of materials to archaeological aspects of their study in an attempt to fill a ‘gap’ in the literature. It is a foregone conclusion that a poorly conducted scientific enquiry generates second-rate or inconsequential results, just as a poorly structured set of archaeological research objectives can also lead to ill-considered or inconsequential conclusions, so obviously both should be conducted at a high standard. This distinction between the scientific and archaeological aspects of archaeological science ought to be a false one: ideally they should form a seamless continuum in which both contribute in meaningful ways, but this is rarely the case.

A chapter on the principal techniques of chemical analysis is provided, which focuses especially on those mentioned in the rest of the book (Chapter 2). The remainder of the book is structured so that each chapter includes a definition of the materials considered (glass, pottery, metal and stone), followed by the ways in which the materials are obtained from the environment, how they may be refined, and, in the case of ceramics, glass and metals, how they were transformed by heat in kilns and furnaces. A range of specific examples of raw material sources/quarries/mines and the basic reasons why the materials were transformed by heat are discussed. The structures of the installations in which these transformations occurred, the kilns and furnaces, are also discussed; the fuel necessary, the gaseous atmosphere produced and the resulting effect on the materials is described.

The initial sections of each chapter are intended to provide the ‘bare bones’ for later sections in each chapter. They are not intended to be exhaustive; a book could easily be written about (almost) any single aspect considered – and it should be noted that only inorganic materials are dealt with here. Nevertheless, the intention is to provide a rounded picture, and within the scope of the book the evidence for the impact of industries on the environment is also considered such as pollution and the impact on vegetation as a result of obtaining fuel by clearance or woodland management (for example).

Although some aspects of archaeology are touched on in initial parts of each chapter, a fuller integration of scientific investigations with the archaeology of production sites and beyond is presented in the second part of each chapter in the form of a series of case studies. Each case study, which builds on the information presented in the first parts of the chapter, provides a different set of links between archaeology and science, depending on the material concerned and the social, economic or political spheres in which the industries were pursued. A different set of case studies could easily have been chosen and somewhat different forms of integration between archaeology and science might have been achieved. However, the examples that have been chosen are intended to highlight quite specific relationships between the industries concerned and the context in which the materials were produced.

The discussion of each case is also, in part, dependent on the breadth and depth of the investigations which have been carried out in each area of study. Scientific investigation of early Islamic glass production relies on excavations of an industrial complex in Syria which revealed a glass workshop with furnaces; scientific analysis of glass from the site attempts to investigate ‘workshop’ assemblages of glass addressing the problems and limitations of proof of potential recycling as opposed to evidence of local production among such assemblages. In the case studies of pottery, the manufacture of Chinese celadon ware has been chosen because of the comprehensive survival and excavation of pottery kilns and associated complete working areas, coupled with the scientific characterisation of the pottery produced and other ceramics used in the manufacturing process. In total contrast, the characterisation of early medieval pottery in England has been selected even though it might be assumed that there would be little mileage in attempting such a characterisation. Early medieval pottery fabric is often described as ‘unpromising’ from a petrological point of view. Nevertheless, not only is it possible to show how the image of ‘household’ production for the immediate demands of the local community had to be revised following this work, it also serves to highlight the ways in which pottery distributions changed with the emergence of urban life later in the first millennium. In addition, a post-processual interpretation of characterised early medieval pottery is presented. The example of early (Bronze Age) copper exploitation in Jordan has been selected because it provides a perfect example of where archaeological excavation of early copper mines and processing areas has been investigated and linked to the scientific investigation of the emergence of the earliest copper metallurgy in the world. The introduction of iron for the first time is used as a means of discussing the complexities of technological innovation before focusing on a case study of an exemplary excavation of an iron production site and experimental work which is based on some of the archaeological findings. In the section on stone, the continuing debate over the transportation of the Bluestones to Stonehenge hinges on the interpretation of some thought-provoking geological, landscape and scientific research (Chapter 6).

Each case study therefore provides an opportunity to examine different relationships between archaeology and science which, in some cases, go well beyond a functional interpretation of various material uses. The use of scientific techniques cannot always provide the answers to questions about how materials were produced and used. Much depends on the political, religious, economic and social environments in which the artisans worked. These parameters would clearly have affected the procedures used in ancient production processes. There is every reason to suspect that ‘ancient chemists’ existed, who studied the properties of the materials they made and that those properties were affected by a change in the raw materials they used. Raw materials would have been recognised by their physical characteristics (colour and perhaps hardness or fracture characteristics). Again, when reading this, there is the danger that one is drawn into an assumption that stone with better fracture characteristics was quarried at the ‘expense’ of a nearby stone type shown to have poorer fracture characteristics – but, in the case of polished stone axes, this is clearly shown not to be the case. Over and above the study of the use of stone of particular tensile strengths for the manufacture of Neolithic stone axes, the results have shown that some stone of inferior fracture characteristics was distributed over the widest zone. This is a good example of how easy it might be to make false assumptions about the use of raw materials in the past based solely on their material properties and to ignore aspects of human behaviour which determine their use and which are not obviously connected to positivism. The perception of raw material characteristics and the potential importance of the locations where they were quarried can therefore play an important part in raw material selection. The Chinese even distinguished between ‘lovely metal’ (bronze) and ‘ugly metal’ (iron) which may have determined the uses to which they were put.

Although ‘ancient chemists’ would not have been aware of specific chemical impurities which might have affected the behaviour of materials at high temperatures, such impurities may have affected the colour of the material. By working a particular material over generations there is every reason to accept the hypothesis that artisans would have been able to locate the same material and prepare it in the same way each time so as to recreate, and predict, the same working properties. Ancient technologists, if not able to ‘dissect’ a material into its chemical/mineralogical components would have had a highly developed sense of sight (colour changes, material transformation), smell (a particular gaseous atmosphere or even of a raw material), feel (the coarseness of a material) and taste.

Museum collections used to be displayed in a way which tended to split materials into categories; this categorisation would, in some cases, be related to the ways in which materials were stored and there-fore documented in the museum. In writing this book one of the areas which has been highlighted is not so much the differences between different production industries, but the areas of overlap between them. Ancient high-temperature industries (pyro-technology) have a range of characteristics in common. The consideration of using specific bricks to withstand the temperatures of smelting metals or melting glass in furnaces, or firing pottery in a kiln will have had areas in common; the use of specific types of fuel at different times in a firing cycle was knowledge which would be unlikely to have remained ‘tied’ to a specific industry; the sources of silica to temper pottery, provide a ‘flux’ for metal-smelting and to make glass are liable to have been a common resource; the exploitation of minerals to produce metal, colour glass and colour glazes is yet another example of where there may have been overlaps in the exploitation of raw materials. These are just a few examples of where communication between groups of artisans may have led to cooperation and articulation with specific routes of trade or exchange. However, at the same time there is also a potential tension in which such cooperation may not have occurred. A range of social, political and ritual factors may have determined tight norms which affected the development of industries in which technological aspects of particular specialisations may not have been shared. There is also the possibility that some aspects of industries may well have overlapped with areas of domestic life and therefore have been perceived as ‘less different’, without the application of strict social constrictions.

Clearly it is possible to be positivist in each case and accept Auguste Compte’s form of empiricism, but in so doing the affects of strict social norms on the development of technologies, for example, are ignored. Why, for example, was a glassy substance made and incorporated in faience long before glass was made separately and made into objects? The temperatures necessary for melting glass had been achieved in the manufacture of copper alloys thousands of years before. Lemonnier (1993: 3–4) notes that

Ideas about technical elements, actors, processes and results have thus to be compatible with, as well as part of other broader social relations and logic that appear to influence and shape the representations directly involved in a human group’s technology and, therefore, in the production of artefacts and in technical actions themselves.

Archaeological and archaeological–science investigations can begin to answer some of these questions, but another important source of information comes from the historical evidence. If texts are available, they can be used to augment the scientific findings – or should the problems be tackled in the reverse order? As in all of the case studies reported in this book, one of the primary areas which one is attempting to contribute to is a definition of the niche, or role, that the industry and its products played in society; the social and economic systems of Anglo-Saxon and early medieval Europe were worlds apart from those of Ottoman Turkey, so there would have been both similarities and significant differences in ways in which the organisation and function of the pottery-making industries articulated with society.

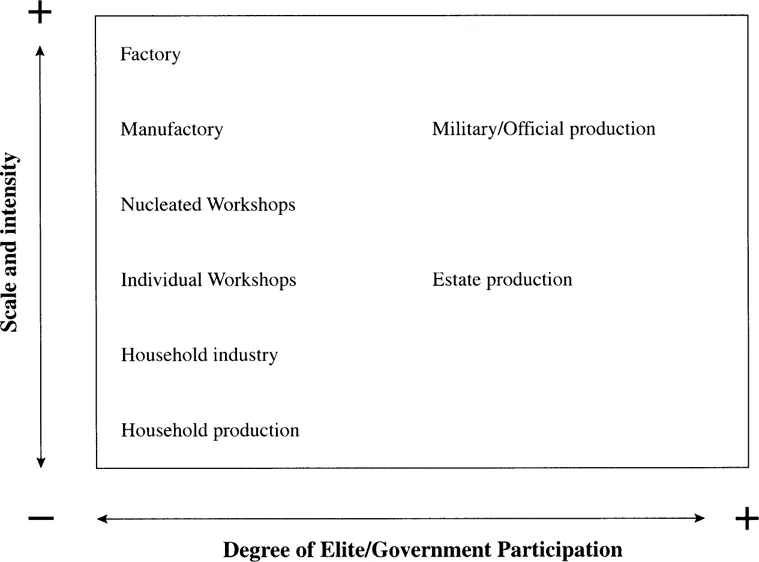

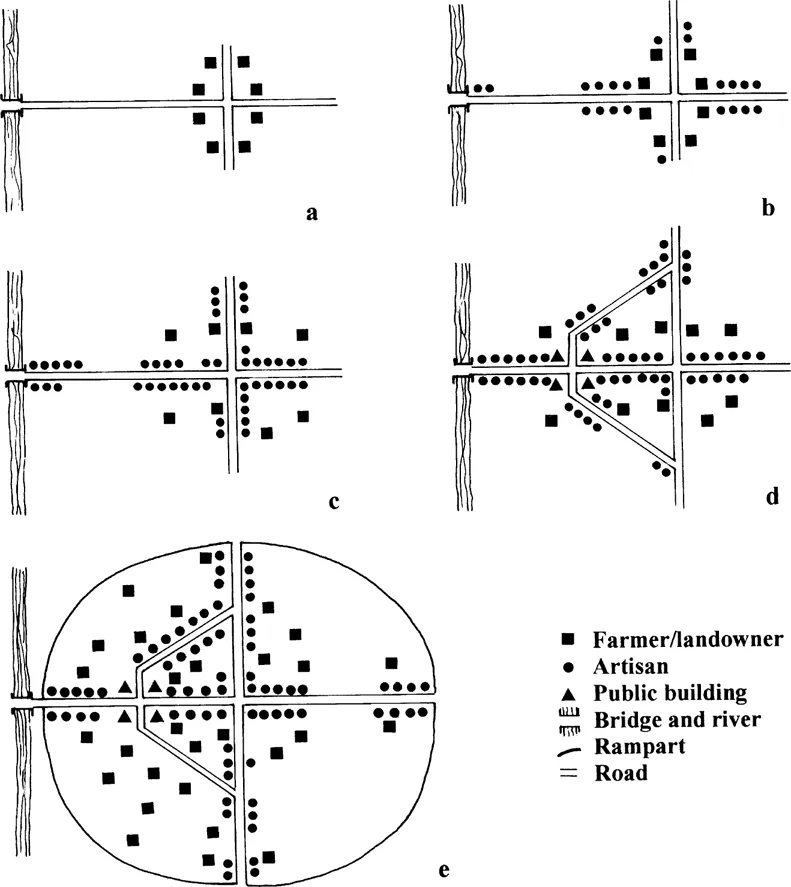

Clearly the social and economic context in which production occurred will have affected the degrees of industrial specialisation, discussed in detail by a range of authors, but perhaps the first comprehensive consideration was Peacock’s (1982) study of specialised production, particularly the Roman pottery industry, based not only on the intensity and scale of production, but also on the degree of participation by elites or the government (see Figure 1.1). This is obviously a model which was designed to apply to the ‘regimented’ Roman society; it does however draw together several important interrelated factors. This model of production went beyond that of van der Leeuw (1977) in which intensity and scale were perceived as being inseparable. The location of industries and its relationship to the structure/development of society, including the centralisation of industries (see Figure 1.2) has also been addressed by a range of researchers (Collis 1984; Costin 1991; Henderson 1991) and they have stressed the importance of location of industries in the landscape.

Figure 1.1 The organisation of production in the Roman world

(after Peacock 1982).

Figure 1.2 The centralisation of settlement and industry in late Iron Age Europe

(after Collis 1984).

The research concerned directly with the chemical characterisation and analytical investigation of raw materials, products and by-products linked to a high-temperature industry can be summarised. Figure 1.3 provides a summary of the stages at which archaeological materials can be investigated scientifically, including the important selection of materials from different types of archaeological context. Scientific analysis can be considered as a basis of the scientific investigation of excavated remains of industries and should also fall within the broader consideration of ancient production in which the form of the industry is considered. An attempt to chemically characterise raw materials should be made. Often this can present practical problems. Sampling of metal ore lodes, for example, can be difficult because they are chemically and structurally heterogeneous (Ericson et al. 1982; Craddock 1989: 195). If the ancient mining site can be located, analysis of any by-products of purification processes should be attempted. Secondly, analysis of artefacts from a production site, such as crucibles, furnace linings, slags and moulds, should be carefully planned, paying attention to the archa...