Handbook of Oil and Gas Piping

a Practical and Comprehensive Guide

- 148 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

The objective of this practical oil and gas piping handbook is to facilitate project management teams of oil and gas piping related construction projects to understand the key requirements of the discipline and to equip them with the necessary knowledge and protocol. It provides a comprehensive coverage on all the practical aspects of piping related material sourcing, fabrication essentials, welding related items, NDT activities, erection of pipes, pre-commissioning, commissioning, post-commissioning, project management and importance of ISO Management systems in oil and gas piping projects. This handbook assists contractors in ensuring the right understanding and application of protocols in the project.

One of the key assets of this handbook is that the technical information and the format provided are practically from real time oil and gas piping projects; hence, the application of this information is expected to enhance the credibility of the contractors in the eyes of the clients and to some extent, simplify the existing operations. Another important highlight is that it holistically covers the stages from the raw material to project completion to handover and beyond. This will help the oil and gas piping contractors to train their project management staff to follow the best practices in the oil and gas industry. Furthermore, this piping handbook provides an important indication of the important project-related factors (hard factors) and organizational-related factors (soft factors) to achieve the desired project performance dimensions, such as timely completion, cost control, acceptable quality, safe execution and financial performance. Lastly, the role of ISO management systems, such as ISO 9001, ISO 14001 and OHSAS 18001 in construction projects is widely known across the industry; however, oil and gas specific ISO quality management systems, such as ISO 29001, and project specific management systems, such as ISO 21500, are not widely known in the industry, which are explained in detail in this handbook for the benefit of the oil and gas construction organizations.

Features:

- Covering the stages from the raw material to project completion, to handover and beyond

- Providing practical guidelines to oil and gas piping contractors for training purposes and best practices in the oil and gas industry

- Emphasizing project-related factors (hard factors) and organizational-related factors (soft factors) with a view to achieve the desired project performance

- Highlighting the roles of ISO management systems in oil and gas projects.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Section 1

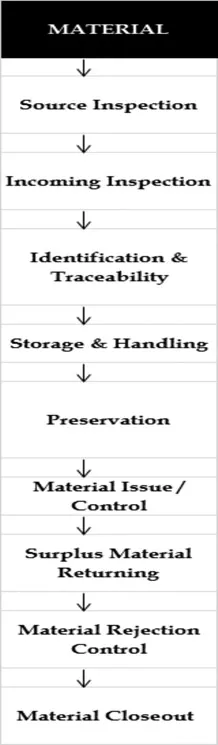

Material

- The importance of oil and gas piping materials and its inspection at source.

- The process of incoming materials inspection at site.

- The dos and don’ts of storage, handling and preservation.

- The process of material issues and control at site.

- The importance of surplus material management and material rejection control.

- The procedure for material closeout.

1.0 Introduction

1.1 Source Inspection at Vendor Premises

- a) Local purchase orders – the SIC will expedite this inspection through the QA/QC department.

- b) Overseas purchase orders – the SIC will expedite this inspection, either with the QA/QC department personnel or by using a third-party inspection agency.

- a) Purchase order/work order.

- b) Applicable client specification.

- c) Client-approved ITPs, procedures, method statements, etc.

- d) Client-approved welding procedures, NDT and testing procedures.

- e) Client-approved FAT procedures.

- f) AFC drawings.

- g) Client-approved product data sheets.

| DOs | DON’Ts |

| | |

| • Pre–inspection meeting (for long lead delivery items). • Availability of client–approved documents. • Availability of competent resources with vendor. • Availability of materials/status (all MTCs shall be either “ORIGINAL” or “CERTIFIED TRUE COPY” signed and stamped by TPI). • Establish the method of resolving technical queries and application of deviation request. • Establish the method of communication. • Establish the method of reporting progress/ schedule/recovery plan/non–conformances. • Establish the inspection and test schedule. • Establish the date of FAT. • Establish the date of final inspection. • Establish the contractual delivery date. • Establish the final documentation requirements. • Establish the logistics methods. | • Don’t start the work without approved PO/WO. • Don’t start the work without client–approved documentation. • Don’t deploy incompetent inspectors (PCR and TPI) to perform inspection. • Don’t deploy inspectors (PCR and TPI) without cli... |

Table of contents

- Cover

- Half Title

- Title

- Copyright

- Contents

- Preface

- About the authors

- List of appendices

- List of abbreviations

- Overall process flow chart

- Praise for this work

- 1 Material

- 2 Fabrication

- 3 Welding

- 4 NDT

- 5 Erection

- 6 Pre-commissioning

- 7 Commissioning

- 8 Post-commissioning

- 9 Project management

- 10 ISO standards

- Appendices