- 240 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Lubrication in Practice

About this book

This book summarizes basic lubrication theory, its types and properties, and covers some specific applications of lubrication: diesel and petrol engines, hydraulics, compressors, machine tools and cutting oils. It then focuses on the storage and handling of lubricants, and on lubrication planning.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1 Theory and Basic Principles

The basic purpose of lubrication is the minimisation of friction and wear. Normally, the lubricant is required to perform various auxiliary duties, cooling or cleansing for example, but these secondary roles will be ignored in this chapter.

Friction is defined as the force resisting motion when two contacting surfaces are moved relative to each other. In a dry system, this force is a result of interaction between the surfaces involved; a fundamental difference exists in the nature of this interaction depending on whether the motion is of a sliding or a rolling character. In a lubricated system, these mechanisms will be weakened to the extent that a coherent fluid film is interposed between the surfaces and an additional but lesser force dependent on the viscosity of the fluid will be present.

Where complete separation is attained, the lubricant viscosity becomes the controlling parameter, and the condition is termed hydrodynamic lubrication. Where surface interaction continues to exert a significant effect, the term boundary lubrication is used.

In the absence of definite contamination, wear is the result of friction and in a simple case is roughly proportional to it. Again, different mechanisms exist; differentiation should be made between the roles of adhesion, abrasion, corrosion and fatigue, even though the final damage may be the end-product of a combination of these mechanisms.

The ensuing sections of this chapter expand on this generalised summary of basic features and examine the function of the lubricant in greater detail.

NATURE OF SURFACES AND DRY FRICTION

An understanding of the fundamental mechanism of friction presumes an appreciation of the nature of nominally flat surfaces on a microscopic scale. This shows a finely polished finish as a series of hills (asperities) and valleys (troughs) of finite dimensions, while normal engineering finishes are viciously contoured. Hence, if one such surface is brought in contact with another the actual contacting points are few and correspond to the limited number of high asperities on one surface that meet corresponding points on the other. These few junctions must bear the total load, and pressures at these points are very high, causing virtual welding (adhesion) of one point to another. The force of sliding friction, therefore, equates to the force required to shear these junctions, the strength of which are dependent on the load but not on the apparent total area of contact. For chemically clean surfaces this force is very high, but in the normal practical case it is considerably weakened by contaminant films of oxide, moisture and occluded gas which are present on any normal surfaces. Where materials of dissimilar strength are slid together, a secondary term must be included to cover the additional force required to plough the asperities of the harder material through the softer one.

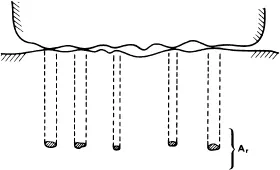

Therefore, in its simplest form the equation governing sliding friction (see figure 1.1) can be shown as

| where | Ar | = | real contact area of ‘welded’ junctions (dependent on load and yield characteristics of materials), |

| S | = | shear strength of junctions, | |

| p | = | force required to plough the harder asperities through the softer material (again dependent on load and yield characteristics). |

The above theoretical derivation of the force that resists motion when one surface is slid over another cannot be applied to the case where one surface is rolled over another except insofar as micro-slip occurs. In pure rolling, the greater part of the resistance, which is of considerably lower order of magnitude, is due to hysteresis losses in the materials themselves and sub-surface plastic deformation under conditions of high stress. In the practical case, ball bearings for example, the simplicity of this concept is marred by such confusing factors as skidding and cage restriction which add complexity to the problem and partially re-insert the features attributed to sliding friction.

General lubrication

From the foregoing considerations, it will be appreciated that the prime purpose in lubrication is to interpose between the surfaces a quantity of low-shear material that is adequate to prevent or at least minimise asperity contact. The extent to which this can be achieved by engineering design, either throughout or partially during normal service conditions, is an important yard-stick of success.

HYDRODYNAMIC LUBRICATION

Hydrodynamic lubrication is the term used to cover the regime where complete separation of the moving surfaces has been attained throughout the majority of service. Its achievement depends on geometrical design and maintenance of adequate speed of movement.

The establishment of a lubricant film of satisfactory thickness is dependent on several conditions from which the load-carrying capacity of the film and hence the ability of the surface to remain separated under load can be established.

Qualitatively the controlling factors for full-film condition are as follows:

Attitude | Surfaces must adopt a very slight taper or wedge attitude to generate a film pressure |

Sliding velocity | Needed to drag sufficient oil into the contact by viscous resistance |

Oil supply | Minimum quantity of oil needed to fill the clearance and make up losses from the edges of the surfaces |

Viscosity | A viscous attraction of the oil to the surfaces and flow determines the thickness of film generated |

These requirements are expressed mathematically in the classic Reynolds[1] equation which may be written in the general form that assumes an incompressible oil and two-dimensional conditions:

| where | h | = | oil film thickness, |

| u | = | sliding velocity, | |

| w | = | load/unit width, | |

| p | = | instantaneous oil pressure, | |

| η | = | absolute viscosity, | |

| x | = | linear parameter, | |

| z | = | radial parameter, |

suffixes 1 and 2 being used to denote maxima and minima in the system.

Plain journal bearings

The above conditions are most easily satisfied in the plain journal bearing having a continuous oil supply at mid-length and a small radial clearance between the journal and bearing.

Figure 1.2 shows a bearing at its three stages of full-film separation. When starting from rest at (a) the journal rests on the bottom of the bearing with the surfaces in contact; as it starts to rotate a slim wedge of oil is dragged between the surfaces and they separate (b). As the journal speed increases the film thickness increases to further displace the journal to its stable running position (c). From this the importance of tapering film thickness afforded by the bearing clearance will be noted. In practice this clearance will, of course, be very small – of the order of 1 × 10−3 of the journal diameter.

In this simple case, the bearing has been considered as being full of oil before start up. However in most practical cases oil is supplied by a pump connected to the same shaft so that the bearing must rotate for the first few revolutions without additional oil. During this period the lubrication depends on residual oil left on ...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Preface

- 1 Theory and basic principles

- 2 Types and properties of lubricants

- 3 Diesel and petrol engine lubrication

- 4 Lubrication of water and steam turbines

- 5 Industrial gas-turbine lubrication

- 6 Lubrication of gears and drives

- 7 Hydraulic transmissions

- 8 Compressor lubrication

- 9 Lubricating machine tools

- 10 Mobile plant and agricultural equipment lubrication

- 11 Grease lubrication

- 12 Cutting oils

- 13 Metal rolling operations

- 14 Planning for all lubrication requirements

- 15 Lubricant storage and handling

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Lubrication in Practice by W. L. Robertson in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Industrial Engineering. We have over one million books available in our catalogue for you to explore.