- 392 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Practical Extrusion Blow Molding

About this book

Outline proven methods from planning and manufacture to product testing, this work reports on the most effective means of producing plastics by the extrusion blow moulding process. It supplies data on materials, performance standards and testing methodologies developed in industry with proven reliability and cost effectiveness.

Information

1

HISTORY OF BLOW MOLDING

Sabel Plastechs, Inc.

Moscow, Ohio

Moscow, Ohio

1.1 INTRODUCTION

Extrusion blow molding is a technique for producing a hollow product. This is accomplished by forming a heated tube of a thermoplastic material called either a parison or preform and placing it in a blow mold containing a female cavity. Once the parison is in the blow mold and it is closed on the heated thermoplastic parison, the parison is inflated with a gas, usually air, that blows the heated parison to take the form of the mold cavity. The mold allows the heated thermoplastic material to cool, exhausts the gas, and then the mold is opened to extract the formed plastic product.

The main advantage of blow molding is its ability to produce varied designs of hollow thermoplastic articles. Extrusion blow molding offers flexibility of article design, handle ware, and intricate shapes with the many different thermoplastics that are in the marketplace today to satisfy customer requirements.

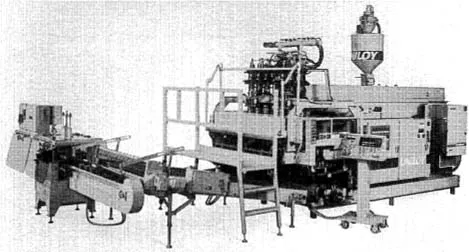

Courtesy of Johnson Controls, Inc., Plastics Machinery Division, Manchester, Ml.

Extrusion blow molded thermoplastic containers are today the choice of the consumer. Extrusion blow molded articles are lightweight, safe, recyclable, low cost, easy to handling, water clear or color enhanced, and easy to use (Fig. 1.1).

1.2 HISTORY

Credit for originating the blow molding industry in the 1930s is given to the Hartford Empire Company However there is evidence that the Egyptians and Babylonians blew plastic materials into various utensils. Synthetic plastics were blown commercially in the 1880s when celluloid was blown into items, such as baby rattles, hair brush backs, ping-pong balls, doll parts, cutlery handles, and jewelry. Methods involved softening sheets with heat or immersion in hot liquids followed by placement in crude molds and blowing with air. Hollow articles made from celluloid and cellulose acetate continued to be produced by these methods well into the 1930s.

Figure 1.1 Courtesy of Johnson Controls, Inc., Plastics Machinery Division, Manchester, Ml.

Enoch T. Ferngren is credited with being the first to make blown plastic items in the “modern era” of blow molding. Mr. Ferngren along with William Kopitke, designed and produced a mechanical device to produce blown plastic articles and sold it to the Hartford Empire Company in 1937. In 1940 the Plax Corporation was formed for blow molding and in 1940 produced hollow Christmas tree balls from cellulose acetate. Owens Illinois Glass Company was experimenting with all available plastics on a modified ram injection machine and produced 20 cc bottles via the injection blow molding process. Owens Illinois Glass company supplied canteens and 100 cc polystyrene bottles to the United States Army Medical Corps during World War II. Only a few products could be packaged in plastics in the 1940s due to the poor barrier properties of the plastics plus the flavor and taste transmission.

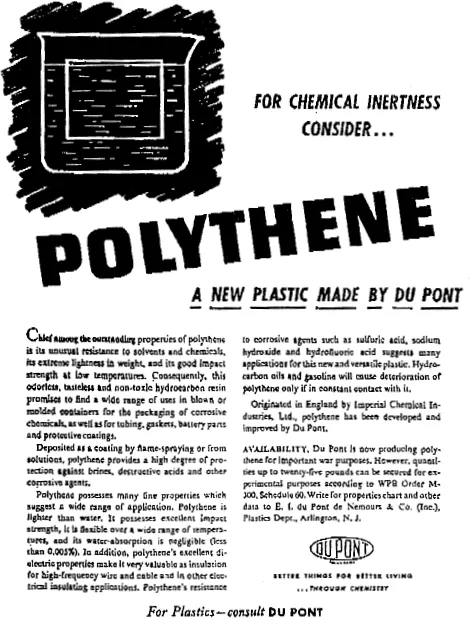

From the 1930s and well into the 1940s, many innovations were tried to allow blow molding the plastics available then. Hydraulics were being used for simple motions, and the more complicated motions were done by mechanical means. Steam and crude electrical elements were tried as heating media. The plastic materials used were cellulose acetate, polystyrene and some polyvinyl chloride. The industry finally blossomed into reality when two things took place in 1945. Low density polyethylene (LDPE) was patented in 1937, and the first commercial plant went on stream in 1939. The first available LDPE was used for the war effort. However, in 1945, a small quantity became available for commercial use (Fig.1.2). Plax introduced the “Stopette” deodorant squeeze bottle in 1945, and over five million units were sold. The industry had its first real commercial success.

Until this time all the machinery for blow molding was developed by the blow molders. The success of the “Stopette” squeeze bottle opened the door, and companies that built rubber machines and injection machines began in earnest to design and build blow molding machines. However, only small items were considered possible to blow mold until high density polyethylene (HDPE) became commercially available to the industry and particularly for blow molding in 1956.

In 1957 there were only three blow molders listed in the SPI Directory and in 1962 Directory this had grown only to thirteen which could produce bottles.

In 1945 Mr. James Bailey authored an article describing indirect, direct, and diaphragm methods that had been investigated and stated that the future of blow molding would be in extrusion and injection blow molding.

There were many inventions and improvements in the entire plastics industry from 1945 to 1950. However, the major advances were made from 1950 into the early 60s. Commercial blow molding machines were being offered by Bekum, Kautex, and Fischer, and Continental Can had developed the Mills wheel (see Tables 1.1 and 1.2).

Figure 1.2 1945 advertisement for a polyethylene made by DuPont.

Once HDPE became commercially available in 1956, end users felt they had a rigid plastic that could replace other materials, such as corrugated cardboard, glass, paper, molded pulp, and the original plastics, such as PVC, polystyrene, LDPE, and cellulose acetate.

Table 1.1

Blow Molding: 1930–1994

Blow Molding: 1930–1994

Equipment Development | |

1930 | Fernplas Corporation blows cellulose acetate with a machine |

1935 | Ferngren patent for extruding a molten tube into a closed mold and inject air |

1935 | First modern injection machine imported into USA |

1937 | Ferngren and Kopitke make and demonstrate first mechanical device to blow mold. Ram injection used. |

1938 | BASF extrusion blow molds in Europe |

1939 | Plax operates blow molding machines to make 25,000 blow molded items per day |

1939 | Electrically heated extruder developed |

1942 | Owens-Illinois patents an injection blow process with core pins |

Other Developments Important to Blow Molding | |

Existing plastic processing machine modified for blow molding. | |

Specific designs for blow molding | |

Only ram injection machines available. Extrusion well established. | |

Injection parison and shift to blow mold developed. Tube cutting, needle blow, hollow tube extrusion, tube transfer to blow mold, pinch tube to make parison, and other basic operations resolved. | |

Available Plastic Materials | |

Cellulose acetate (1927), PVC (1927), acrylics (1936), cellulose acetate butyrate (1938), nylon (1935), polyvinylidene chloride (1939), polystyrene (1938), cellulose propionate (1945), ethyl cellulose (1936), experimental LDPE (1942), polyesters (1942) | |

Blow Molded Products | |

Christmas tree balls (1939), hollow ware, toys, brush backs, baby rattles, ping-pong balls, small bottles, canteens, toilet floats, novelties | |

In the early 1960s other plastics were being developed, such as polycarbonate, acrylics, polyacrylic nitrile, phenoxy, polypropylene, nylon, and polyacetals. These new materials offered clarity, rigidity, grease resistance, less permeation by certain gases, chemical resistance, and enabled plastic bottle producers to become competitive with glass, metal, and composites.

In 1964 a comprehensive summary was published of the six methods that are basic to much that has since been developed: injection-transfer, hand transfer, fixed mold with interrupted extrusion, alternate flow using manifold extrusion, extrusion, and using molds with continuous extrusion plus the horizontal or vertical multistation rotary.

In 1961 an article was published on how to design heads, dies, and molds plus information on flow, blow ratios, die swell, cooling, and blowing techniques.

Raw material companies such as DuPont, Union Carbide, Phillips Chemical, and Dow as well as universities were studying the new polymers, and test methods for melt flow, shear rate, molecular weight, tensile strength, elongation, and crystallization, etc. were being given to molders to understand their process better.

From a mere three blow molders listed in 1957, there were 97 in 1959 and 24 suppliers of blow molding machines mainly due to the growth of HDPE as a blow molding material. In 1963 it was reported to SPI that over 195 million bottles were produced (Tables 1.3 and 1.4).

In 1963, approximately three companies were supplying bottles less than eight ounces to the plastic blow molding industry, Wheaton, Brockway, and Owens-Illinois.

High density polyethylene became the dominant blow molding material in the late 1960s and is the largest volume material used in the blow molding industry today, more than 57% of the total blow molding market. PET is growing and will continue to grow from its 33% share in 1977. Other resins, such as AN, PVC, PS, PC, LDPE, and coextrusions make up the remaining 10% of the blow molding market.

Table 1.2

Low Density Polyethylene Period: 1945–1958

Low Density Polyethylene Period: 1945–1958

Major Deve... |

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Preface

- Contributors

- 1 History of Blow Molding

- 2 Selecting the Proper Equipment for Industrial/Technical Blow Molding

- 3 Start-up and Initial Production

- 4 Selecting a Blow Molding Material

- 5 Extrusion Blow Mold Design

- 6 Auxiliary Equipment

- 7 The Use of Regrind

- 8 Deflashing, Trimming, and Reaming

- 9 Testing of Extrusion Blow Molding

- 10 Automation, Simplicity, and Profit for Blow Molding

- 11 Troubleshooting Guide for Common Blow Molding Problems

- Appendix A: Marlex/Phillips Chemical Company Technical Information Bulletin 31, Blow Molding: Markets, Processes and Equipment; Controlling Wall Distribution by Programming and Die Shaping; Material Requirements for Part Performance

- Appendix B: Marlex/Phillips Chemical Company Technical Information Bulletin 32, Part 1. Blow Molding Highly Irregular Shaped Parts With Moving Mold Sections; Part 2. Blow Molding Highly Irregular Shaped Parts With Multiple Airing Lines

- Glossary: Plastics Terms

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Practical Extrusion Blow Molding by Samuel L. Belcher,SamuelL. Belcher in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.