- 504 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

"Assists users, developers, researchers, and manufacturers in the design, selection, development, and application of seals and sealing systems for fluids."

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Topic

Physical SciencesSubtopic

Fluid Mechanics1

Terminology and Concepts

1 THE SEALING PROBLEM

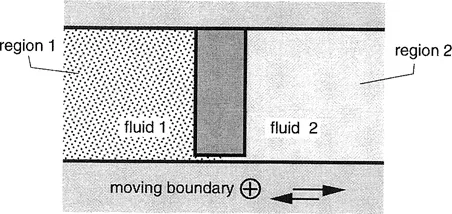

The generalized problem of sealing between the moving components of a machine is represented diagrammatically in Fig. 1 and can be stated as the control of fluid interchange between two regions sharing a common boundary. In “dynamic” sealing situations there is significant relative sliding motion at the boundary, the motion being predominantly parallel to the boundary. In “static” sealing situations such motion is essentially absent. Examples of dynamic seals include rotary mechanical seals, rubber lip seals, labyrinth seals, and piston rings. Static seals include gaskets, metal O-rings, and sealants.

The boundary is normally cylindrical, e.g. part of a reciprocating or rotating machine element such as a shaft, piston, or rod; but it can also be a plane annular end face. Overriding structural, design, or tolerance considerations often necessitate a relatively large gap between the stationary and moving surfaces, which cannot therefore perform the sealing function unaided. The gap can be reduced to suitably small dimensions by introducing additional components for this purpose, i.e. a “seal.” Fluid flow through the gap may be driven by a variety of physical processes, for example a pressure gradient, concentration gradient, temperature gradient, velocity gradient (including viscous shear), molecular interaction (adhesion and cohesion) or body forces such as gravitation, inertia, or electromagnetic forces.

Figure 1 The basic sealing problem.

2 FLOW AND LEAKAGE

Any clearance, however small, permits the passage of fluid molecules in either direction. Sealing is therefore a matter of degree; it is never absolute. The terms “leaking” and “sealing” are often used in a loose colloquial way, but in serious engineering they must be defined in a way appropriate to the context. Leakage is normally considered to be fluid flowing outwards past the seal to the region surrounding the machine being sealed. However, under some circumstances leakage may he ambient fluid passing inwards, past the seal, to mix with the fluid inside the machine and may be pumped inwards by the moving components. Depending on the application, contamination caused by such inward leakage may or may not be acceptable.

The following modes of leakage will now be distinguished.

Diffusion: The size of a typical gas or vapor molecule is less than one nanometer (10−9 m); it can therefore diffuse through the smallest engineering gaps, even pores in a machine casing or seal component. Even a glass sphere containing a vacuum slowly fills with helium, which diffuses through the wall from the surrounding air! Very costly sealing systems are therefore required if leakage of hazardous gas or vapor is to be controlled to a very high standard. However, if the fluid to be sealed does not create an environmental nuisance—e.g. compressed air or steam—relatively large leakage rates may be tolerated and low-cost sealing systems can be used. Most industrial applications fall somewhere between these extremes.

The diffusion process is driven by concentration gradient, as random molecular motion tends to level out differences in concentration.

Convection: Air flow induced by the rotating parts of a seal can move fine liquid droplets outwards through a sealing gap, especially in noncontacting seals. Equally, rotating parts can induce inward air flow, which transports dust particles or liquid droplets from the environment into the space being sealed. Convective leakage is very sensitive to the detailed geometry in and around the sealing gap.

Pressure flow: This is the leakage mode that is usually of most concern in practice. Liquid-phase leakage due to a pressure difference is frequently apparent as dripping or flowing liquid. For nonhazardous fluids, sealing systems are defined as technically tight if there is no liquid leakage. Under this definition, a thin liquid meniscus at the atmospheric side of the seal is not normally considered to be leakage even though there may be evaporation to atmosphere (‘vapor emission’). The leak rate due to pressure flow increases with the pressure gradient and decreases with the viscosity of the fluid, if nothing else changes.

Pressurized gases, or vapor, also leak in response to pressure difference. Gas or vapor-phase leakage also results if a volatile liquid changes phase as it passes through the sealing gap. The phase change may be due to the reducing pressure or frictional heating, or both. The large increase in volume as the phase changes has the useful effect of throttling the flow and so r...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Preface

- I. Introduction to Fluid Sealing Technology

- II. Rotary Seals: Rubber and Plastic

- III. Reciprocating Seals

- IV. Flexible Packings: Rotary and Reciprocating

- V. Mechanical Seals

- VI. Noncontact Shaft Seals

- VII. Static Seals, Bellows, and Diaphragms

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Fluid Sealing Technology by Muller,Heinz K Muller,Heinz Muller in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Fluid Mechanics. We have over one million books available in our catalogue for you to explore.