- 256 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Practical Laser Safety

About this book

Contains the latest revision of ANSI standards for safe use of lasers. A workbench guide that explains how a laser works, what a laser beam can do to biological tissue and eyewear lenses, and how to work safely with lasers. Annotation copyright Book News, Inc. Portland, Or.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Characteristics of Lasers

Lasers come in many sizes, shapes, and forms. Some lasers are as small as a grain of sand, while some large systems cover more than an acre of floor space when completely assembled. Certain lasers require toxic reactive materials, yet others need only a source of 110 V electricity (Fig. 1.1). Beams produced by some lasers have circular cross sections while other forms of beams include several small beams clustered together. Most lasers are mass produced, or “off-the- shelf,” and are readily available from manufacturers, but many are “built from scratch” for special applications. The variety of lasers appears to be limited only to the imagination of the experimentor and the application in mind.

Beginning as a scientific curiosity in the early 1960s, laser energy absorption has found a multitude of applications, and the technology is considered just “emerging.” This magnificient tool, in little more than 20 years, has revolutionized the industrial, medical, research, and art worlds. Lasers are now used by engineers, scientists, doctors, artists, and in seemingly countless other professions. Advantages of the laser have been realized by chemists, supermarket managers, printers, welders, construction contractors, computer manufacturers, surgeons, and others. Perhaps the biggest user of all is the military. Targeting, rangefìnding, submarine tracking, and communications are among the many applications used in the military services. Probably the industry most affected by the laser is the communications field of fìberoptics, estimated to be a three billion dollar industry by 1990. Not yet mentioned are uses in the fields of video discs, holography, entertainment, laser-fusion, metrology, spectroscopy, material cutting, and surveying. The ultimate use of laser beams is the death ray.

Figure 1.1 Photograph of a simple laser system requiring only 110 V electrical source for activation. Students are shown in a classroom where a low-power HeNe laser is being used. (Courtesy of Hughes Aircraft, Carlsbad, California.)

Laser rays can be controlled to extremely low powers to focus on microscopic spot sizes so that a 5-μm diameter hole can be “drilled” into one wall of a 150-μm diameter microballoon of glass, while other beams can be generated to powers of maximum possible output to be focused on fusion targets of the same size microballoons (Fig. 1.2). This versatility added to the other properties of coherent light make laser energy adaptable to a veritable plethora of applications. These characteristics include a variety of wavelengths (each having different qualities), the mode of propagation (either a continuous flow of photons or a burst of photons acting like a bullet of light, in a single pulse or in a series of pulses), focusability and dispersion (expansion) of the light rays through optical gear, absorption and transmission of the different wavelengths of various materials, and additional features newly discovered or being developed in physics and chemistry laboratories.

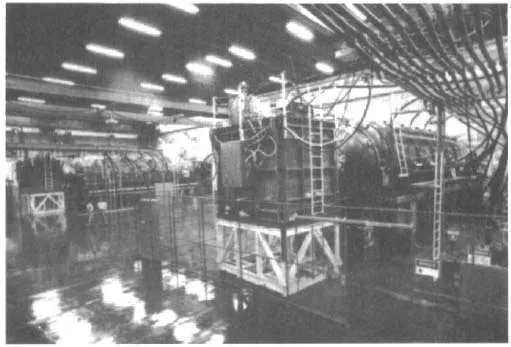

Figure 1.2 Photograph of a portion of the world’s largest CO2 laser system, Antares, used in laser fusion research. (Courtesy of Los Alamos National Laboratory, Los Alamos, New Mexico.)

A few basic properties of the photons at hand need be known and understood to provide a safe laser environment and for the safe control of the potential hazards of laser light. These fundamental laser characteristics are described below.

WAVELENGTH

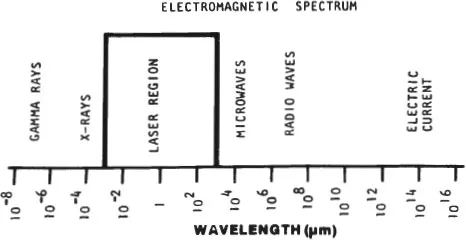

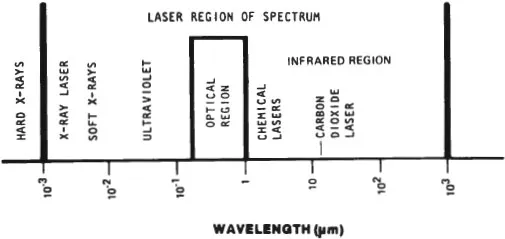

Because the wavelength of a laser beam determines its adsorption and transmission characteristics when interacting with materials, it is vital to know precisely the position of the wavelength of any laser beam in the electromagnetic spectrum. The wavelength produced by the lasing material of a laser is expressed in units of linear measurement as shown in the table in Figure 1.3. The wavelengths of essentially all lasers in common use are near the 1.0 micrometer (μm) spectral line, therefore, all units of laser wavelengths will be confined to the micrometer, or micron, as this unit is commonly known. That portion of the spectrum in which laser wavelengths are located is shown in Figure 1.4. Notice that, in describing the various regions assigned to laser radiation, there are three categories:

Figure 1.3 Representation of the electromagnetic spectrum that includes position of lasers.

Figure 1.4 Expanded portion of electromagnetic spectrum showing location of laser wavelengths.

1. Ultraviolet

2. Ocular focus

3. Infrared

Proliferation of laser technology has resulted in an increased number of nontechnical users, therefore, it is logical to designate these spectral regions in simple terms. More sophisticated users will understand that in laser safety applications it is not necessary to use such terms as actinic ultraviolet (having photochemical properties) or near ultraviolet, or near infrared or far infrared. It is important, however, to know that the ocular focus region is a range of wavelengths from approximately 0.4 to 1.4 μm, which is focused by the eye’s components with a power of approximately 100,000 times. (Components of the eye are described in Chap. 2.) Transmission of this portion of the spectrum through the eye results in these wavelengths being retinal hazards because these light rays reach the retina and are absorbed there. It is also important to know that this wavelength range, 0.4-1.4 μm, contains two distinct subranges. One range, 0.4-0.7 μm, is the visible portion of the spectrum and provides the light rays the eye uses to see. All wavelengths, or colors, varying from the blue colors near 0.4 μm, through the green and yellow colors near 0.5 μm, and including the orange and red colors from 0.6 to 0.7 μm are visible to the eye in this region. Transmission of light rays in the other range, 0.7-1.4 μm, also is permitted by ocular components except that the retina, which also absorbs this range of wavelengths, does not “see” them. In other words, this upper portion of the ocular focus region is invisible.

Owing to the focusability of some wavelengths by the eye as described above, these rays must be intercepted before they can cause harm to the retinal tissues, since even low energy laser beams, if concentrated by a factor of 100,000 (105), can cause damage to the eye as described in Chapter 3.

Wavelengths lower than 0.4 μm of interest in laser technology are located in the range of the spectrum designated as ultraviolet and do not pose as great a hazard to the eye because the outer components, especially the cornea, absorb essentially all of the rays’ energies. The same is true of the portion of the spectrum called the infrared, which is above 1.4 μm. Ultraviolet and infrared wavelengths are not transmitted through the cornea and other exterior parts of the eye. These wavelengths are not focused on the retina, and, therefore, magnification of the rays’ energies is not possible. Selection of protective eye wear should take this property of the nonfocusable laser beams into consideration as described in Chapter 8.

CONTINUOUS WAVE (CW) LASERS

Many applications of laser light require a steady stream of photons. These types of beams can be constructed of a variety of lasing materials; thus, the wavelengths available are extensive. Beam characteristics are readily measured because the beam is on continuously, reaching a constant condition, or steady- state. The laser beam diameter, for example, is a very important property in evaluating safety aspects of the beam and, with CW lasers, can be readily determined. The output power of a CW laser can be measured by simple instruments and is always presented in watts.

PULSED LASERS

Pulsed laser beams are actually “bullets” of light. Some pulses of laser light are created by chemical reaction, but usually the pulse is created by “chopping” a small portion of a CW beam either mechanically or by electronic methods. Terms used with pulsed mechanisms are choppers, Q-switched, and mode-locked. The descriptive units used to describe the length in time of a single pulse are listed as follows:

sec = second | ||

msec = millisecond | = .001 sec | = 10−3 sec |

μsec = microsecond | = .000,001 sec | = 10−6 sec |

nsec = nanosecond | = .000,000,001 sec | = 10−9 sec |

psec = picosecond | = .000,000,000,001 sec | = 10−12 sec |

The definition of a pulsed laser per ANSI Z136.1 is one that delivers its energy in the form of a pulse or a train of pulses of less than 0.25 seconds per pulse. Most commercial pulsed lasers operate in the range of milliseconds to picoseconds. Only in the past several months have subpicosecond pulses been reported in research literature.

The energy of a pulsed laser is concentrated in a “bullet” of light. It damages biological tissue acoustically, that is, by a mechanical blast interaction. For example, a nanosecond pulse (10−9 sec) produces a 0.3 meter (approximately one foot) length of light traveling at the light speed of 3 × 108 meters/sec. Consequently, low energies in the ocular focus region (0.4-1.4 μm) can produce retinal damage. All pulsed lasers emitting in the ocular focus wavelength band should be considered Class 4 in the ANSI Z 136.1 classification scheme which is described in Chapter 6.

POWER AND POWER DENSITY OF BEAM

In evaluating a CW laser environment, it is essential to know the output power of the beam and the beam diameter in order to determine the watts per square centimeter (W/cm2), the characteristic of the beam described as the beam “power density.” The technical term for power density is irradiance, but power density is more descriptive and will be used throughout this book. Power densities may vary from a few W/cm2 to hundreds of W/cm2.

To obtain the power density of a beam, of course, the beam diameter must be known. For manufactured lasers it will be listed in the laser literature accompanying the equipment. Usually, the cross section of a beam is a simple circular area, the beam being a simple solid cylinder of light. However, if the diameter must be measured, technical assistance is required because most solid cross section cylindrical beams have a “gaussian” distribution which describes a beam of higher intensity near the center and lower intensity near the exterior. Some other cross sectional shapes are described in more technical publications listed in the references at the end of this chapter.

ENERGY AND ENERGY DENSITY OF BEAM

The watt (W) is the measurement of power in a CW laser beam. The joule (J) is the measurement of energy in a pulsed beam. The relationship between the watt and the joule is as follows:

or

The energy intensity within a pulsed beam depends on the beam diameter in terms of square centimeters, just as described for the CW beam intensity. It is vital to know the beam diameter so that the joules per square centimeter, or energy density, can be determined. Technically, J/cm2 is defined as radia...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Dedication

- Preface

- Table of Contents

- 1. Characteristics of Lasers

- 2. Eye Components

- 3. Laser-Eye Damage Thresholds

- 4. Skin Damage Thresholds

- 5. American National Standards Institute’s ANSI Z136.1 “Safe Use of Lasers”

- 6. Classification of Lasers by ANSI Z136.1

- 7. Engineering Control Measures of ANSI Z136.1

- 8. Selecting Laser-Protective Eyewear

- 9. Laser Personnel Medical Surveillance

- 10. Critique of the ANSI Z 136.1 Standard

- 11. ANSI Z131.2, Laser Safety in Fiber Optics

- 12. ANSI Z131.3, Laser Safety in Health Care Facilities

- 13. Hazards Associated with Lasers

- 14. Special Safety Rules, Policies, Safety Committee Organization, and Emergency Procedures

- 15. Summary: Elements of a Successful Laser Safety Program

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Practical Laser Safety by Winburn in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Electrical Engineering & Telecommunications. We have over one million books available in our catalogue for you to explore.