![]()

Part I

![]()

Chapter 1

The world-wide scope of manual materials handling

Introduction

Manual materials handling (MMH) creates special problems for many different workers world-wide. Labourers engaged in jobs which require lifting/lowering, carrying, and pushing/pulling of heavy materials have increased rates of musculoskeletal injuries, especially to the back. The world community is beginning to recognize the problems MMH presents for workers. It is necessary to look at the scope of MMH problems to get some idea of the true size of the overall problem. In the following sections, after a review of some of the statistics available, the legislative actions of various countries with respect to MMH are addressed.

Scope of this guide

This guide is intended to include all activities involved in MMH (lifting, pushing, pulling, carrying, and holding) as opposed to other existing guides that focus only on manual lifting. The recommendations are provided in the form of design data that can be used to design different MMH activities.

The guide is divided into two parts. Part I outlines the scope of the problem, discusses the factors that influence a person’s capacity to perform MMH activities and/or that should be modified to reduce the risk of injuries, and reviews the various design approaches to solve the MMH problem. Part II provides specific design data in seven distinct chapters (Chapters 4, 5, 6, 7, 8 and 9, and 11) for six different MMH areas. Chapter 10 describes a generalized procedure for designing and evaluating multiple-activity MMH jobs. In Chapter 12, a procedure for determining rest allowances is described. The last chapter of the guide describes various mechanical devices that are available to aid MMH activities.

Available statistics of various countries

While most countries acknowledge the problem MMH creates for workers, accurate statistics of injuries attributable to MMH are still hard to find. According to Sweden’s National Board of Occupational Safety and Health (1983), the most common types of injury to workers in that country are strains and sprains due to overexertion of body parts. These injuries due to overexertion account for almost 18% of injuries, while another 12% of personal injuries to workers are skeletal. When injuries are classified by occupation, the category ‘materials, goods, and packaging’ accounts for more than 23% of injuries, by far the largest proportion of any one segment of the labour force (National Board of Occupational Safety and Health, 1983).

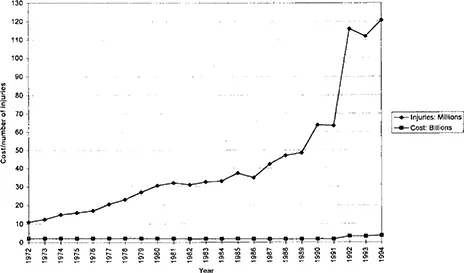

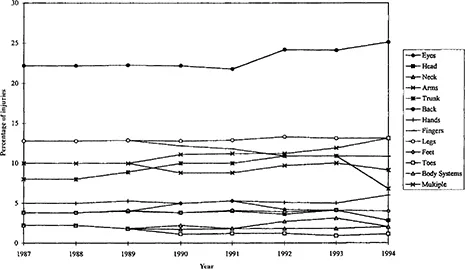

Other countries report similar findings. In 1982, the Health and Safety Commission reported over 70000 injuries due to MMH in the UK. During the financial year 1986-87 there were at least 110000 manual handling injuries, half of which resulted in more than 3 days’ absence from work (Health and Safety Commission, 1988). In 1988-89, 27.5% of reported accidents in the UK involved manual handling. The cost of these accidents, including lost output, medical treatment, and individual suffering, exceeded £90 million. The total annual cost of musculoskeletal disease exceeds £25 billion (Health and Safety Commission, 1991). Rawling and O’Halloran (1988) report that Australia’s State Electricity Commission of Victoria (SECV) estimates that 34% of compensation costs are paid to workers suffering injuries due to MMH. In Luxembourg, data from the Association d’Assurance contre les Accidents showed that acute back disorders accounted for 2% of occupational accidents reported (or 286 out of 15559 reported). Of these, 181 cases (or 78%) of back disorders involved lifting/lowering and carrying and another 26 cases (another 11%) resulted from pushing/pulling loads (Metzler, 1985). Figures 1.1 and 1.2 show the relationship between the number of injuries and their cost from 1972 to 1994 and the magnitude of back injuries in relation to injuries in other parts of the body from 1987 to 1994, respectively, in the USA. It is clear from these figures that not only are injuries to the back more frequent than to any other body part, but the rate of rise in cost is also very high, especially in the last few years. Manual handling has been known to be one of the prime causes of back injury. It is reported in the USA that 60% of people suffering from lower-back injuries claim overexertion caused the injury. Furthermore, back injuries result in much more lost job time (Chaffin, 1987). It has been reported by the National Institute of Occupational Safety and Health in a recent report on the National Occupational Research Agenda (NIOSH, 1996) that the total cost of back injuries in the USA in 1991 was between 50 and 100 billion dollars.

Figure 1.1 Number and cost of work injuries in the USA. Compiled from data published by the National Safety Council (1972-1994).

Figure 1.2 Proportion of injuries by part of body injured. Compiled by the National Safety Council from data from various state Labor Departments, 1987-1994.

Many more countries lack data on the magnitude of occupational injuries caused by MMH. For practical purposes, there are no regular statistics on MMH injury in the Netherlands (Zuidema, 1985), Germany (Hettinger, 1985), or Denmark (Biering-Sorensen, 1985).

Legislation of various countries addressing the problems of MMH

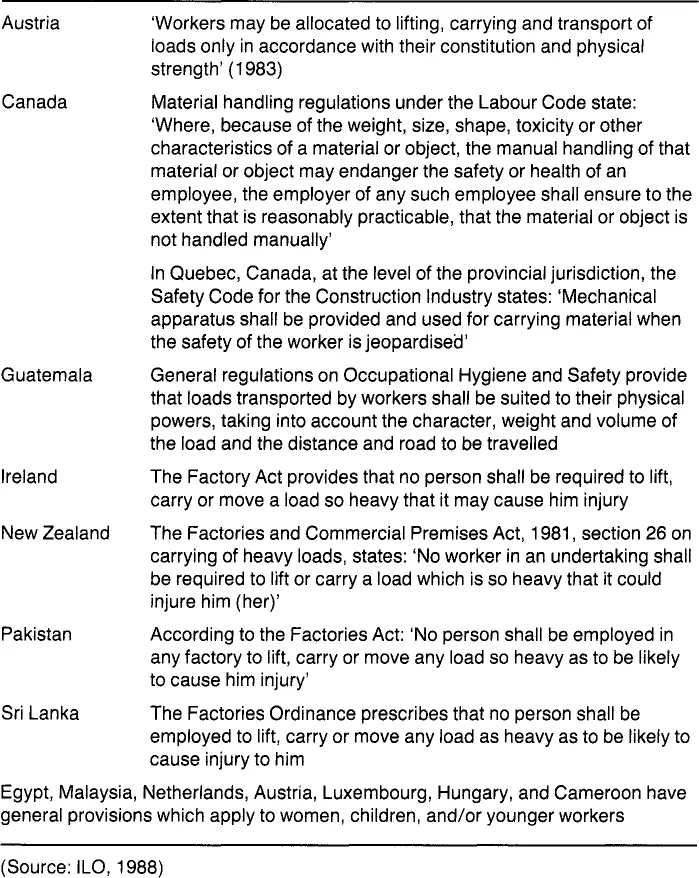

The seemingly poor state of gathering statistics and reporting information on MMH injuries, however, has not led to the denial of the problem nor inhibited legislative action on the part of several governments. Table 1.1 shows countries that are currently known to have some type of government-established guidelines or laws dealing with MMH. Table 1.2 shows additional countries with current guidelines, advisory standards or legislation addressing MMH. Table 1.3 lists the limits on weight to be lifted and carried in different countries.

NIOSH has addressed the concern for industrial lower-back injuries by developing a set of guidelines followed in the USA. The NIOSH guidelines are advisory in nature but they are generally adhered to by US industries. The NIOSH guidelines do not provide a rule for lifting capacity but they do indicate safe limits. The so-called safe limits tend to be slightly lower than capacity, but the level of protection they provide is unknown.

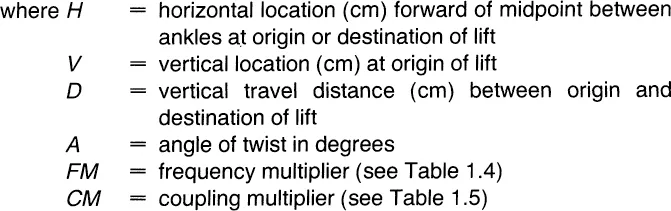

The NIOSH Work Practices Guide to Manual Lifting equation (1981) was revised in 1991 (Waters et al., 1993). The new revised equation utilizes Recommended Weight Limit (RWL) instead of the Action Limit (AL) and the Maximum Permissible Limit (MPL) of the 1981 guide. The RWL is based on three criteria: the biomechanical criterion, the physiological criterion, and the psychophysical criterion.

The Recommended Weight Limit is defined as:

Australia has several advisory standards in reference to MMH. The Australian Council of Trade Unions (ACTU) has a standard which provides guidelines for manual handling (ACTU, 1983). This standard suggests that (1) no worker be required to handle a load exceeding 16 kg unaided, and (2) no worker be required to handle packages, bags or loads exceeding 240 kg over a 15 min period. It is interesting to note that the ACTU guide also includes NIOSH manual lifting guidelines in an appendix as a reference.

Table 1.1 General Provisions

In the state of Victoria, Australia, an Occupational Health and Safety Act set forth regulations (Department of Labour, 1988) with the objective of reducing MMH injuries and their severity. The act requires employers to assess and control risks associated with MMH activities on the job. The regulation provides a number of factors for employers to assess risk to employees. If a risk has been assessed, the employer must redesign the manual handling task to remove or reduce the risk, even to the point of including the introduction of mechanical aids and training.

The UK has many acts addressing MMH in a more or less direct manner (David, 1985). Among them are the following: the Mines and Quarries Act 1954, Section 93; Agriculture (Safety, Health and Welfare Provisions) Act 1956, Section 2; Factories Act 1961; and the Offices, Shops and Railway Premises Act 1963. None of these acts, however, sets any kind of limits or presents guidelines for MMH. In 1991, the Health and Safety Commission drafted prop...