eBook - ePub

What Every Engineer Should Know about Concurrent Engineering

- 272 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

What Every Engineer Should Know about Concurrent Engineering

About this book

This work offers a step-by-step approach to the overall concurrent engineering (CE) development process, presenting both fundamental principles and advanced concepts, while focusing on rapid product development and cost-effective designs. The book also provides an introduction to Cost Driven Design, with specific examples on how to minimize expenses by understanding the basis of product costs. The process of concurrent engineering is explained from initial planning to production start-up.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Chapter 1

Concurrent Engineering Background

What Is Concurrent Engineering?

The simplest definition of Concurrent Engineering (CE) is the simultaneous development of product and process. The difficulty of performing the task of concurrent development of product and process is not so obvious in this definition. As one might imagine it is hard, if not impossible, to define the process of making a product before a product design has been created. Many important details are not understood and known. In fact, for much of the Industrial Revolution until the 1980’s, the most commonly practiced method was to develop the product and process in a predominantly sequential fashion. This allowed the design engineers to develop the product based upon technology and concepts that they believed to be competitive in the marketplace and adequate for repeatable manufacturing.

Why Didn’t The Sequential Process Continue To Work?

There are three primary reasons that caused the design process to evolve into a concurrent process.

1) Rapid Pace Of Technology. Technology was advancing at an ever-increasing pace. Some companies were able to take advantage of the new technologies and convert them into products gaining market share. This put tremendous competitive pressure inside the companies that remained behind. Design groups were being forced by these business pressures to develop products in record time, and to provide competitive advantage to regain the lost market position. Once companies fell behind the technology curve it was difficult and sometimes impossible to catch up. Time-to-market, which is a term used to identify the time between the initial idea to the time the first customer product is shipped, became the competitive strategy and rallying point for many companies. The luxury of long product and process development cycles was doomed.

2) Forced Design Cycle Compression. As engineers became pressured to develop products more rapidly, manufacturing input or marketing input became low or non-existent on the priority list. Product development was all engineers had time to do. Engineers became focused on the management dictated requirements and specifications. Product inputs from other functions that might cause a slip in the design schedule were often ignored. Thus, as marketers learned more about the customers’ needs and expectations, and manufacturing engineers learned more about the cost to produce the product and manufacturability issues, few of their recommendations could be incorporated into the design under development. Any accepted recommendations were incorporated only if they did not have an impact on the overall product development schedule.

As a result major mistakes were made. Products missed their target in the marketplace. Designs were unproducible or had much higher manufacturing costs than expected. The finished designs were often delivered significantly later than planned or expected. This was due to the multiple design iterations necessary at the end of the development cycle to correct design deficiencies or inadequacies. Thus, companies learned that simply hurrying the design process was not the answer to overall time reduction in the product development.

3) Emerging Information Technology And Methodologies. New design technologies were emerging to help the development process. The emergence of workstations and personal computers allowed computer-aided design (CAD) and computer-aided engineering (CAE) to become significantly more cost effective and more widely used. As a result CAD and CAE capability improved. CAD was not only a way to eliminate the tedious tasks of accurate drawings but it also provided new capability such as multiple views, three dimensional solid object views, electronic assembly and others. Computer-aided engineering (CAE) tools, especially simulation, were being developed to help analyze products in a more technically robust and detailed way.

Electronic communications emerged as a way to speed up the process. By making the communications electronically written, and logged through electronic mail, individuals could be held accountable for the accuracy and dependability of their input. Additionally, the fundamentals of project management could more easily be tracked. Specifically, the time individuals took to respond to requests, and the time taken to respond to action items, once difficult to pin down after the fact, could now be tracked through the logging of messages in electronic mail routines.

Additionally, several new structured methodologies emerged which resulted in better ways to understand and predict the product functionality, cost or market acceptance. As examples, material and assembly costs were minimized using Design For Manufacturing (DFM) techniques. Quality Function Deployment (QFD) emerged as a better way for the marketing, manufacturing and engineering functions to assess and agree on key product features.

Thus, the information technology and the structured methodology foundation required to reshape the development process into a concurrent engineering process was emerging.

Organizational And Behavioral Factors

Besides the three primary factors, there were organizational and behavioral factors that contributed to the problems associated with sequential design.

Organizational Segmentation Forces Multiple Iterations. Many companies organized their design function in a segmented fashion. As an autonomous organization it required minimal involvement from both marketing and manufacturing in the day-to-day activities. This segmentation lead to the development of organizational boundaries affecting the development cycle. The design function, being measured on completed designs, was anxious to turn the designs over to manufacturing. Manufacturing, being measured on cost efficiency, wanted to make sure new designs were producible and did not have unnecessary costly operations. This lead to a phenomenon called “over-the-wall” syndrome. Here each function passes the drawings or designs back and forth until they achieve functional success. This method in itself developed into a formidable barrier to the implementation of concurrent engineering (See Figure 1).

When the sequential design cycle was forced into compression, engineers working in this environment did not have the time to devote to their functional role and the additional responsibility of understanding the market and the newest trends in manufacturing. They substituted opinions from their manufacturing associates and information from trade journals, sales brochures, and catalogs in place of solid manufacturing capability studies or formalized manufacturing start-up efforts. They used relatively few discussions with their current customer base to solidify market needs and expectations. They allowed their own engineering opinion to outweigh the marketer’s view.

Figure 1 Organizational Focused Development. The traditional method of handing off a design has been referred to as the “over-the-wall” syndrome, where the design organization passes the designs to manufacturing thinking they are complete, manufacturing then passes it back to engineering, attempting to improve producibility of the design. This process could go on for months, frustrating both organizations.

(The artwork is derived from Lotus SmartPics for Windows. © 1991 Lotus Development Corporation. Lotus and SmartPics are registered trademarks of Lotus Development Corporation)

Additionally, when engineers consulted the manufacturing and marketing functions on specific issues, it was seldom with enough time for the marketing or manufacturing functions to develop thorough and well-supported answers. Thus, opinions given were individual experienced based instead of data based such as those provided by modeling techniques or market research. This supported the problem of inadequate inputs, and gave design engineers the feeling that their views were the only ones they could trust. Thus, because of this attitude, oftentimes even excellent inputs from solid marketing and manufacturing data were ignored.

As a result of these behaviors, products were designed a minimum of three times. Once during the concept phase, when marketing plans and inputs were required for management approval. Once during the development phase when engineers did what they believed was needed oftentimes losing substantive key features and marketing needs from the previous step. The third time when the product started in manufacturing, eliminating detail design errors, and improved the products’ ability to be produced economically.

Loss Of Trust In The Design Function. Because of the constant changing and evolution of the product, the full expectations of the marketing and manufacturing functions were rarely achieved. Consider the organizational trust issues when product compromises were made by engineering often without effectively looking at the marketing or manufacturing impacts. As previously mentioned, these compromises often resulted in problems when the product was brought to market. Key features were missing, or were non-competitive and manufacturing was unable to produce the product as inexpensively as engineering had predicted. The impact of these problems took its toll over time. As a result, the functions of engineering, marketing and manufacturing, became very distrustful of one another and viewed each other as a necessary evil to getting their jobs done.

Thus, in summary the design cycle compression caused the problems of a segmented organization to translate into severe business problems, such as long design cycles, cost overruns, missed market opportunities and lack of cross-organizational trust.

What Are The Key Elements Of Concurrent Engineering?

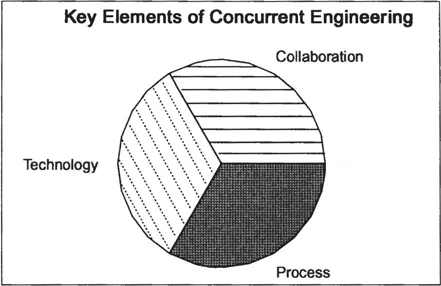

Concurrent engineering is comprised of three fundamental elements. They are collaboration, information technology, and process (See Figure 2).

Figure 2 Concurrent Engineering Fundamentals. There are three significant elements in the implementation of concurrent engineering: collaboration among team members including the virtual team, implementation of information technology as an enabler, and the establishment of formal concurrent processes involving engineering, marketing, and manufacturing.

Collaboration

Collaboration means to work together or to cooperate with. In the normal context of concurrent engineering collaboration is usually expressed in terms of teams or teamwork. However, collaboration and teams are important distinctions. Industry teams can operate without deliberate collaboration between the team members. They can simply be a collection of individuals with a common cause. Each person, in order to succeed, follows his own agenda and measurement criteria as established by his individual function. This non-collaborative behavior has lead to many product failures, and is a non-trivial problem inherent to industrial cross-functional teams.

The typical measurements of product success consisting of cost/performance, competitive advantage, delivery on time, are generally not valued to the appropriate level of significance by non-design engineering functions. The result of this is a major conflict for the non-design engineering team member, especially manufacturing and marketing. Since new product introductions often negatively affect traditional business measurements aimed at manufacturing efficiency or controlling marketing expense, the non-design engineering team members can easily cause negative consequences to their own career paths. Any trade-offs committed to by the team member that are good for the product development but negatively affect the organizational metrics have the potential of producing disastrous results for the team member’s career. To improve this condition, several industrial studies have pointed to appropriate methods to use to recognize and reward team members and to promote collaborative behaviors. These are discussed in later chapters.

When appropriately used, effective collaboration occurs beyond the team. It includes the full function or organizations within the company, as well as suppliers, customers, consultants, resellers, distributors, and in some cases collaboration with other companies on the development of a single product or technology. Several companies have co-developed very successful products where the strengths of one company are balanced with the strengths of another company. Such is the case when an industrial design firm is used such as Frog Design Inc. Their expertise in understanding appeal, human factors, and functionality in the users environment have lead to many successful and award winning designs, and improved product success in the marketplace.

Thus, in establishing a concurrent engineering environment the infrastructure that drives the behavioral change towards collaborative activities is key. The infrastructure such as reward systems, goal setting, individual recognition, functional measurements, etc. are of major importance in supporting a collaborative environment. Individuals and their willingness to collaborate both within the company and outside the company are a major factor in determining the success of the concurrent engineering process.

Information Technology

Information Technology in the design process is usually discussed as computer-aided design (CAD) and computer-aided engineering (CAE). Additionally and possibly more importantly, information technology has become the foundation enabler that allows concurrent engineering to happen. This is true in several areas of information technology.

1) Simulation technologies for electronic designs, mechanical designs and manufacturing processes are predictive in nature. These predictions allow problems to be anticipated electronically at a stage when corrections are simple and easy to make.

2) I...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Dedication

- Preface

- Table of Contents

- 1. Concurrent Engineering Background

- 2. Concurrent Engineering, Fundamentally Changing The Overall Process

- 3. How To Form A Concurrent Engineering Team

- 4. Selection Of Key Techniques And Methodologies

- 5. Selection Of Tools

- 6. Market Focus Your Design

- 7. Developing Cost Sensitive Products

- 8. Quality Focused Design

- 9. Development Time Management

- 10. Fitting The Pieces Together

- References

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access What Every Engineer Should Know about Concurrent Engineering by Salomone,Thomas A. Salomone in PDF and/or ePUB format, as well as other popular books in Tecnología e ingeniería & Ingeniería industrial. We have over one million books available in our catalogue for you to explore.