![]()

Chapter 1

Introduction

Asko Sarja

Building and civil engineering has an important role in the service of the societies of our time in:

• providing safe, healthy and convenient conditions for the living and working of people;

• equipping the societal infrastructure for industrial production, logistics and transport on all hierarchical levels of the global economy (local, national, regional and global); and

• participating in preserving the balance of the ecosphere (biosphere and geosphere).

The importance of this mission has been rising with the increasing development of society, and with the increasing level of the standard of living. In order to control the balance for a sustainable development, we need more than the traditional synthetic principles and processes, methodologies, procedures and methods for making rational and balanced optimisations and decisions in all levels and phases of product and production development, design, manufacturing, construction, MR&R, demolition, recovery, reuse and rehabilitation of buildings, civil and industrial infrastructures.

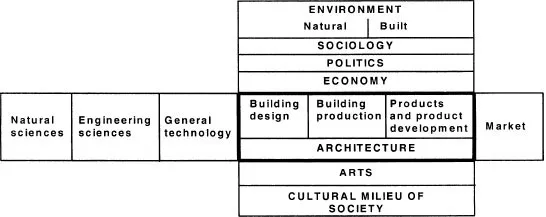

A schedule of the process for innovatively solving the challenge of the mission in the societal context is presented in Figure 1.1 [1]. The generic requirements are demanded by society, owners and users, and are then interpreted as architectural and technical requirements in different levels and time spans:

• for long span in the strategic development of products, organisations, management, production, manufacturing, MR&R (Maintenance, Repair, Rehabilitation and Renewal) and even in End of Life (demolition, recovery, reuse and recycling processes); and

• for short span on the project level in briefing, design, manufacturing, construction and management while in use and in end-of-life processing.

Our current society is based on scientific knowledge, which includes natural sciences (physics, chemistry and biology). In this long- and short-term processing, the applied technical sciences serve as practical tools for technology, and architecture gets support from arts. The objectives and targets of construction are defined in the general politics of each society in connection to environmental, sociological and economic objectives.

Figure 1.1 Development environment of building technology [1].

In the background of the development, there exists the heritage of general culture, arts and architecture of each region and society. Knowledge push is served by natural sciences, engineering sciences and general technology. This knowledge is transferred into technology through design, building production and building products. The entire evolution is strongly controlled by market forces and businesses of the companies [1].

All over the world, societies have identified and accepted the goal of sustainable development to reach a stable social and economic development in harmony with nature and cultural heritage. In social, economic, cultural and ecological aspects, the construction branch is a major player. In ecological aspects, the most dictating is energy efficiency. The building sector is responsible for a major share of all the influences mentioned above. Hence, the goal of sustainable building is a big challenge for civil engineering.

These changes are creating new challenges for construction, which can be tackled successfully only through active and innovative changes in design, products, manufacturing methods and management. Introducing the latest advancements of the new technologies into the solving of the challenges, a major development can be achieved. In the next 10–15 years, we can witness an entirely new generation of building technology. New solutions will be developed, or in fact already are partly existing in prototypes and in limited applications. The advanced technology will then penetrate into more wider applications until it becomes common practice. This evolution phase has started in the second part of 1980s and will be implemented into common practice until 2010–2015.

The construction branch includes building and civil engineering and all their life cycle phases: construction, operation, maintenance, repair, renewal, demolition and recycling. For example, in Europe the construction branch share is 10% of GNP, 15% of employment and 40% of raw material consumption, energy consumption and waste generation. Building and civil engineering structures are responsible for a major share of all the influences mentioned above. Building and civil engineering structures are the long-lasting products in societies. Typically, the real service-life of structures lies between fifty years and several hundreds of years. We know, and this is especially known in Greece, that some of the most valued historic structures currently have even reached an age of several thousand years. This is the reason why sustainable engineering in the field of buildings and civil infrastructures is especially challenging in comparison to all other areas of technology.

In order to reach these objectives, we have to make changes even the paradigm, and especially the frameworks, processes and methods of engineering in all phases of the life cycle: investment planning and decisions, design, construction, use and facility management, demolition, reuse, recycling and disposal. Hence, it is apt to discuss on lifetime engineering. The lifetime (also called whole life or life cycle) principle has recently been introduced into design and management of structures and this development process is getting increasing attention in the practice of structural engineers [2–5].

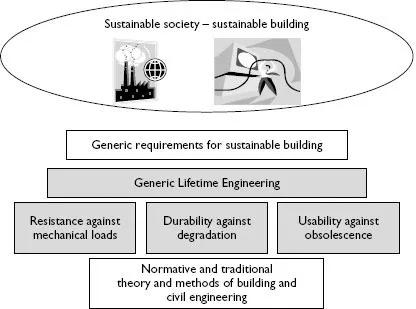

This new paradigm can be called as Lifetime Engineering, defined as a theory and practice of predictive, optimising and integrated long-term investment planning, design, construction, management in use, MRR&M (Maintenance, Repair, Rehabilitation and Modernisation) end-of-life management of assets. With the aid of lifetime engineering we can control and optimise the lifetime properties of built assets with design and management corresponding to the objectives of owners, users and society.

Lifetime engineering includes:

• lifetime investment planning and decision-making;

• integrated lifetime design;

• lifetime procurement and contracting: Integrated lifetime construction;

• integrated lifetime management and MRR&M planning and actions; and

• end-of-life management: Recovery, reuse, recycling and disposal.

The integrated lifetime engineering methodology concerns the development and use of technical performance parameters to optimise and guarantee the lifetime quality of structures in relation to the requirements arising from human conditions, economical, cultural and ecological considerations. The lifetime quality is the capability of the whole network or an object to fulfil the requirements of users, owners and society over its entire life, which means in the practice the planning period (usually 50 to 100 years). The survival life usually includes several service (working) life periods, which follow after a refurbishment (or redevelopment) between the working periods.

Lifetime investment planning and decision-making is a basic issue not only in starting the construction, but also in lifetime asset management. Generally, the investment planning and decision-making is used in evaluating project alternatives, either in planning of a construction project or in MR&R planning. The procedure includes the consideration of characteristics or attributes which decision makers regard as important, but which are not readily expressed in monetary terms. Examples of such attributes in case of buildings are: location, accessibility, site security, maintainability and image.

Integrated lifetime design includes a framework, a description of the design process and its phases, special lifetime design methods with regard to different aspects: human conditions, economy, cultural compatibility and ecology. These aspects will be treated with parameters of technical performance and economy, in harmony with cultural and social requirements, and with relevant calculation models and methods [2]. The optimising planning and design procedure thus includes consideration of characteristics of attributes which decision makers regard as important, but which are not readily expressed in monetary terms. Examples of such attributes in case of buildings are: location, accessibility, site security, maintainability, and image.

Integrated lifetime management and maintenance planning includes continuous condition assessment, predictive modelling of performance, durability and reliability of the facility, maintenance and repair planning and decision-making procedure regarding alternative maintenance and repair actions.

End-of-life management is the last phase of the life cycle, including the selective demolition, recovery and reuse of components and modules, recycling of materials, and disposal of non-usable modules, components and materials.

The role of lifetime engineering as a link between normative practice and the targets of sustainable building is presented in Figure 1.2 [6].

When looking at the statistics of demolitions of buildings and structures, we can notice the following reasons for refurbishment or demolition. Degradation is the main reason for refurbishment of buildings in 17% [7] and in 26 (steel) to 27 (concrete) of demolition of bridges [8]. In individual cases, degradation is a dominating reason for refurbishment or demolition of the structures, which are working in highly degrading environment. Obsolescence is the cause of refurbishment of buildings in 26% [7] and the reason of demolition of bridges in 74% of demolition cases [8]. In the case of modules or component renewals of facilities, the share of obsolescence is still higher. This means that the obsolescence is the dominating reason for demolitions in cases, where structures are working in non-degrading environment.

Figure 1.2 Generic Lifetime Engineering as a link between normative practice and the targets and requirements of sustainable building [6].

A conclusion of this, and a challenge for structural engineering, is that we have to consider the degradation and obsolescence criteria in the design, as well as into the MR&R planning of structures [9]. Hence, we need new methodology and methods for analysis, optimisation and decision-making. This methodology and corresponding detailed methods are included in this book.

This book is mainly based on results of a European research project in the fifth framework program, GROWTH: ‘Life Cycle Management of Concrete infrastructures, Lifecon’, which was carried out during 2001–2003 [10]. Totally eighteen partner organisations from six countries participated in the project. Selected parts of these results were produced as deliveries of the project. The authors of these selected parts of Lifecon results are also the contributors of corresponding chapters of this book.

References

[1] Sarja, A. 1987. Towards the advanced industrialized construction technique of the future. Betonwerk + Fertigteil-Technik, 236–239.

[2] Sarja, A. 2002. Integrated life cycle design of structures. London: Spon Press, 142 pp. ISBN 0-415-25235-0.

[3] Sarja, A., and E. Vesikari, eds. 1996. Durability design of concrete structures. RILEM Report of TC 130-CSL. RILEM Report Series 14. London: E&FN Spon, Chapman & Hall, 165 pp...