- 208 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Buildings with load-bearing earth walls were once widespread throughout Britain and many thousands still survive, including some dating from the fourteenth and fifteenth centuries.

Earth is the ultimate form of 'green' building construction, creating no environmental pollutions and consuming virtually no energy. Subsoil can be dug from or near the site to construct buildings that will meet modern needs and conform to the latest building regulations.

This book describes all aspects of earth building, explaining how earth performs as a building material and providing guidance on how best to repair and conserve existing earth buildings.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Earth Building by Laurence Keefe in PDF and/or ePUB format, as well as other popular books in Arquitectura & Arquitectura general. We have over one million books available in our catalogue for you to explore.

Information

Part 1: Earth construction: methods and materials

Introduction: earth as a ‘green’ building material

The construction and servicing of buildings probably has a greater impact on the global environment than any other human activity. About 30 per cent of the UK’s total energy consumption goes into the servicing of domestic buildings, and a further 8 per cent of the total into the construction of buildings. There is a wealth of published material relating to the need to control resource depletion by reducing energy consumption and to the problems associated with the atmospheric pollution caused by industrial production processes (to which the construction industry is a major contributor). This brief introduction is not, therefore, a polemic, intended to convince the sceptical of the merits of green building. Rather, the aim is to explain how the use of unfired earth and other associated natural materials can play a significant role in reducing energy consumption while at the same time having a minimal impact on the natural environment. In order to do this, it may be helpful to first explain some definitions, or eco-jargon, which sometimes cause confusion, and then to show how earth-based materials perform in relation to these various environmental criteria.

Some terms used in the environmental assessment of building materials and construction methods

- Sustainability. This is a fairly vague and non-specific term, much used but perhaps not always clearly understood. It refers to all aspects of human activity and their impact on the earth’s ecosystem. Central to the concept of sustainability is the idea that the current world population, or at least those in positions of power, have a clear responsibility to safeguard the earth’s remaining resources and its natural environment for future generations. All the terms listed and described below stem from, and form part of, this key concept.

- Energy efficiency. This relates mainly to the consumption of energy in buildings in use. A building can be designed and built in such a way that the absolute minimum amount of energy is used, throughout its lifetime, to provide a comfortable and healthy environment for its occupants.

- Embodied energy, or energy intensiveness, is a measure of all the energy consumed in the extraction, processing, manufacture and transportation of a building component or material up to and including the actual construction process. In a conventional building with a notional 100-year lifespan, the embodied energy input would amount to about 10 per cent of the total energy consumed during this period (B. and R. Vale, 1993). However, according to another source (Borer and Harris, 1998), ‘As new buildings are designed to be more energy-efficient, the energy-in-use portion [referred to above] will fall. . . . The embodied energy factor will then become relatively more significant and could constitute up to 50 per cent of the total energy use of an energy-efficient building over 30 years.’

- Zero emissions. The concept of zero emissions is based on the use of natural materials, employed in such a way that no carbon dioxides or other potentially harmful chemicals are released into the atmosphere. Under this general heading may be included the process known as ‘out-gassing’ or ‘off-gassing’. This refers to the use in contemporary buildings of synthetic materials, which release toxic, sometimes potentially carcinogenic gases from volatile organic compounds and solvents into the interior of a building. Because many modern buildings are of non-breathable construction and lack effective ventilation, the emission of these gases can result in what is known as SBS or Sick Building Syndrome, the potentially damaging effects of which are now fairly well known and understood.

- Natural materials. These are building materials that may be either organic or mineral in origin, either grown in the earth or extracted from it, which are used in unaltered form. This would include, for example, organic materials such as timber, straw and other plant fibres, and animal hair; also earth minerals such as stone, sand, gravel and subsoil. Unlike manufactured materials, natural materials are not processed or modified in a way that requires the consumption of significant amounts of energy.

- Renewable resources. In terms of energy consumption, resources used in the production of buildings may be classified as either renewable or finite. Obvious examples of finite materials are fossil fuels such as coal, natural gas and oil; also rocks containing metalliferous and other mineral ores. Most natural materials are renewable except in cases where they undergo irreversible change through industrial processing, as a result of which they become either non-biodegradable or incapable of recycling.

- Recycling. When a building becomes redundant or, as is often the case, the site it occupies is required for redevelopment, it will be demolished. Clearly, in environmental terms, to demolish a sound, re-usable building for no better reason than that of economic expediency is very wasteful. Although it is possible to recycle some building materials, especially those from nineteenth- or early twentieth- century buildings, the high labour costs of doing this are such that potentially valuable materials often end up in landfill sites, and recycling of cement-based materials such as reinforced concrete, and bricks which have been bedded in strong cement/sand mortars, is virtually impossible. Unbaked earth and other natural organic materials are, by contrast, eminently recyclable. The issues of finding suitable uses for redundant earth buildings and of their economic repair and conservation are discussed in the introduction to Part II of this book.

- Waste materials and their use in building. In a consumerist, throwaway society, where built-in obsolescence is considered normal, the disposal of vast quantities of ‘waste’ material poses a considerable, apparently insoluble, problem. All the more reason, therefore, to take recycling seriously. Waste materials which have traditionally been used in conjunction with earth for building construction include straw, flax, hemp and other organic fibres; also sawmill waste – sawdust and wood shavings. Currently, research is being carried out to assess the potential of other waste materials, including ground glass aggregate and shredded rubber tyres, as elements in mass earth walls (University of Bath, 2002–4).

- It should be noted that the current Building Regulations for England and Wales, unlike those of some other European countries – Germany and Denmark, for example – do not take into account either embodied energy or recyclability in the energy assessment of buildings. This issue is further discussed in Chapter 5.

The performance of earth-based materials

High thermal mass external walls in domestic buildings are considered to be more energy efficient than walls of lightweight construction, mainly on account of their high thermal capacity; that is, their ability to store heat and then to release it slowly when the heat source is removed, in much the same way as a night storage heater. Earth is ideally suited to this form of construction because, although its density is lower than that of concrete blockwork, its thermal characteristics are not dissimilar to those of fired bricks, sometimes marginally better. Earth may be used to construct solid, cavity or cellular walls, and may be mixed with lightweight aggregates to improve its thermal performance (see Chapter 5).

The concept of the embodied energy of building materials is one that is easily understood. However, to calculate precisely the overall amount of energy consumed, from extraction through to construction for a given building material, is a very complex process. The data shown in Table I.1, which has been compiled from various published sources, must therefore be regarded as providing, at best, a rough approximation of energy costs in kilowatt-hours per cubic metre (kWh/m3) (energy required to produce one cubic metre of material).

It is not clear to what extent the data shown in Table I.1 take into account the energy costs of transportation. Energy consumed in transporting materials over long distances can significantly increase their embodied energy input. For example, it has been estimated that if a truck travels a distance of 150 km (93 miles) carrying a load of fired bricks and returns empty, this would increase the embodied energy costs of the bricks by 40 to 50 per cent (B. and R. Vale, 2000). The same applies to softwood timber imported, as it mostly is, from Scandinavia or North America, where it is estimated that the embodied energy of locally sourced timber is only about 15 per cent of that of imported material (Talbott, 1995). Lime and cement are included in Table I.1 for comparative purposes and because the addition of small quantities of lime to earth renders may be justified in certain cases (see Chapter 4). It may be noted that the energy consumed in cement production is about three times that required to produce a similar quantity of hydrated lime. Furthermore, it has been estimated that the manufacture of cement, which is a complex, highly industrialised process, is responsible for 10 per cent of global CO2 emissions. Lime, on the other hand, can be produced locally using fairly simple traditional technology (Wingate, 1985).

Table I.1 Embodied energy consumption of selected building materials

There are many hundreds of surviving limekilns in Britain; an indication of how widespread lime production was in former times, before the advent of industrially produced hydraulic lime and Portland cement from the mid-nineteenth century onwards. Reference to Table I.1 will show that even concrete blocks use around 100 times the energy of that required for earth construction, and that the production of straw, which becomes a waste material once the wheat or barley grains have been separated out, consumes only negligible amounts of energy.

Zero/low emissions. As noted above, in the case of earth, straw and other natural organic products, the amounts of CO2 and other chemicals that they release into the atmosphere are so minute that they may be regarded, relatively speaking, as zero emission materials. With regard to internal emissions, or out-gassing, earth and unprocessed organic fibrous materials are entirely non-toxic and therefore present no risk to health, provided they remain dry. The one exception to this may be the presence of radon gas, which is normally found only in subsoils overlying granite rock formations. Lime, although produced by the high temperature burning of chalk or limestone, is also non-toxic and quite harmless once it has carbonated. In fact, in former times, limewash was valued for its mild antiseptic and biocidal properties, and for this reason was applied to the internal walls of agricultural buildings in which animals were housed.

Renewability and recycling. Earth, although not renewable in the same way as organic materials such as timber and straw is, over very long periods of (geological) time, being constantly created through the weathering of rock. It is a material that is universally available, often at little or no cost, because in many civil engineering and housing development projects thousands of tonnes of unwanted subsoil are excavated, which are then transported, at great cost, to landfill sites that may be located many miles from the construction site. Tristram Risdon, in his Survey of the County of Devon written in the early seventeenth century, describes the process of cob walling, which he concludes by noting that: ‘when any such Walls are pulled down to be re-built, they commonly make fresh Cob with other Earth; the Value of the old as Manure for land sufficiently compensating the Cost of the new’ – an early example of recycling, which has as much relevance now as it did four centuries ago.

Chapter 1: Earth building in Britain – international context and historical background

By R. Nother, with an introduction by L. Keefe

British earth building in an international context: a brief history

It is estimated that at least 30 per cent of the world’s population, some 1.5 billion people, live in houses constructed of raw (unfired) earth. Earth buildings exist in every habitable continent but are far more numerous in hot, arid regions of low rainfall where there is a dearth of timber suitable for building. Archaeological and historical research would suggest that earth has been used for building construction for about 10,000 years, the earliest surviving remains having been found in the Middle East. By the end of the pre-Christian era, earth building had spread throughout all the world’s ancient civilisations, from China through to North Africa and the eastern Mediterranean, and including Central and parts of South America. The earliest recorded building technique is ‘adobe’, unfired mud bricks containing straw. Later, mass earth walls were constructed of earth rammed into timber formwork, and ‘piled earth’ – wet earth with fibre reinforcement, made into balls, which are then thrown up on to the wall head and beaten into place. This technique – which is not dissimilar to that of British cob building – is used in conjunction with adobe bricks to construct large, impressive buildings of up to 10 storeys with walls 30 metres high, in the Middle East and North Africa to this day – an unbroken, centuries-old tradition (see Colour Plates 1 and 2). It is estimated that in China around 45 million people live in houses constructed of either rammed earth or mud brick made mainly from loess – deep deposits of windblown silt laid down during the Pleistocene period (Houben and Guillaud, 1994). When the Spanish and Portuguese arrived in Central and South America, not only would they have brought with them their own, Moorishinspired, knowledge of earth building, but they would also have found a well-established indigenous earth-building tradition. As a result, numerous large structures, including cathedrals, churches and other public buildings, as well as houses, most of which were built with adobe bricks, survive from the Spanish colonial period.

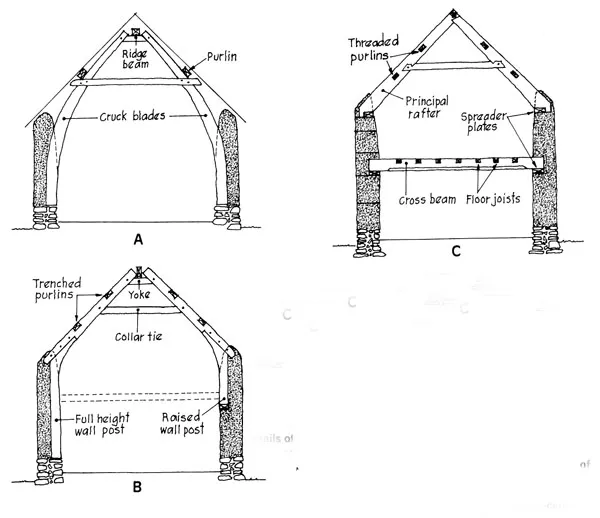

With regard to Europe, although there is evidence of the widespread use of earth construction in the Mediterranean regions in pre-Christian and Roman times, in north-western Europe the picture is rather less clear. There is some evidence that, during the Roman occupation of Britain, rammed and ‘puddled’ earth was used in the construction of military and other buildings, notable examples having been found at Norwich Castle and Verulamium (McCann, 1995) but, not surprisingly perhaps, little else has survived, although evidence has been found of the making and use of unfired earth bricks in Leicestershire (Harrison, 1984). After the Romans departed from southern Britain, having failed either to subdue the Scots or to occupy Ireland, their building technology seems to have been largely forgotten, and for about six centuries building construction remained at a fairly basic level – although carpentry became quite sophisticated towards the end of the period. The walls of all but the highest-status buildings, churches and manor houses, for example, were usually timber framed with an infill of wattle-and-daub or similar earth- or chalkbased materials. The same was probably also true of most of northern Europe, Scandinavia and northern Germany, for example, where much of the Anglo- Saxon British population originated. The earliest examples of mass earth walling in Britain date from the thirteenth century. However, many of these earlier cob or ‘mud’ buildings must be regarded as transitional in the sense that their walls were not fully load-bearing. Their main roof trusses, or principal rafters, rather than bearing directly on the earth wall head, formed the upper part of a ‘cruck’ frame, which was either supported on the stone-pinning course or built directly off the foundation. A variation of this system, found mainly in south-west England from the fifteenth century onwards, was the ‘jointed cruck’ in which the feet of the principals were jointed into curved full or half-height wall posts. Fully load-bearing earth walls became increasingly common from the late sixteenth century onwards and within a hundred years or so came to be almost universally adopted (see Figs 1.1 A to C).

1.1 Typical constructional details of some early cob and mudwall domestic buildings: (A) fourteenth-century cruck frame, (...

Table of contents

- Cover Page

- Title Page

- Copyright Page

- List of illustrations

- Acknowledgements

- Preface

- Part 1: Earth construction: methods and materials

- Part 2: The conservation, repair and maintenance of earth buildings

- Organisations

- Bibliography