Buildings as Engines for Environmental Restoration

Bill Browning

Rocky Mountain Institute

Snowmass, Colorado, U.S.A.

So what is a professional environmentalist doing working in real estate development? When Rocky Mountain Institute got into this thing called “green development”, we thought of it in terms of habitat protection, buildings to be lighter on the earth, energy efficiency, indoor air quality, and material selection. It is about all these things, but it is also more than that.

We are starting to see something much more interesting emerge. We are seeing it emerge among developers, among designers, even from corporations. We are seeing it come out of environmental groups. And we’re seeing it come out of government agencies. Not a lot of it yet, but enough for us to come up and say that green development is a view of real estate development in which you take a real estate development, the act of changing a piece of land, and you use it to generate a financial stream. Yes, it is about making a profit, but you use that financial stream as the engine for undertaking ecological restoration, for financing community development, and even in one case, ethnic dispute resolution. Not what you thought about a real estate developer? So where is this coming from? In some ways, people are starting to respond to what Aldo Leopold said essentially fifty years ago that to be an ecologist is to

walk through the world and be conscious of the wounds around you. What is happening is people are starting to say that it is time to heal these wounds.

On design juries at architectural schools, I keep hearing all this stuff about layers of meaning for example, “Well, this angle in the building is on the ley line between Sydney and Paris.” Great. But if you want a layer of meaning, let’s talk about real layers of meaning. What is this building telling me inherently about the culture of place? What is this angle here telling me about the angle of the sun on the solstice? What does this shape here tell me about the nature of the rainfall patterns and the things that are happening on this site? For me, those are real layers of meaning.

Let’s talk about buildings where you get the opportunity to address green development issues fundamentally from the outset; the NMB Bank building in Amsterdam. It is a bank that in 1978 had a fairly interesting problem: they were viewed as too stodgy and conservative. Their market share was slipping, and they needed to change the way they were viewed.

So they put together a very interesting way of doing design. It’s one that we use frequently, but I wish there was more of it. The building design criteria was only two sentences, from the bank’s board of directors. The first sentence was, “It shall be organic, filled with light, air, green, water, art, and happy employees.” Number two: “It shall not cost one guilder more per square meter than conventional construction.” It is, after all, a bank. Therein lay the challenge.

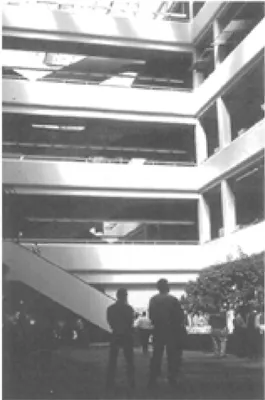

5.01 NMB Bank: main lobby volume

5.02 MNB Bank: gardens and courtyards interspersed over the top of a car park and service areas

How did they address this? Well, they put together a team that involved the architect, who had never designed a commercial building before. He had done nineteen thousand housing units, but never a commercial building. Structural engineers, mechanical engineers, electrical engineers, energy experts, bank employees, landscape architects and artists. And the contractors were there as well.

They were instructed they had to work in a team fashion. They had to work around the big table. And if anyone at any point did not understand what was being proposed, it was within their contract that they had to stop the meeting and get a full explanation. Now that sounds like a torturous design process, but it led to a building that is one of our favorites in the world.

The site was chosen by a vote of the bank employees. They chose the site because it was closest to where most of them lived. There is a half a million square feet sitting on a plinth of three hundred thousand square feet of parking. The bank sits on the roof of the parking garage. The gardens are entirely watered with rainwater collected in cisterns off the roof of the building, together with a solar collector on top of the towers. The windows have a threepart construction. The center section of the window is for view. There are louvers in the upper section of the windows that bounce daylight into the core of the building. And the bottom section is operable. I show this to most mechanical engineers, and they think I’m nuts, talking about a half a million square foot building with operable windows.

5.03 NMB Bank: ‘Flow-Form’ water sculpture integrated with handrail

The building is primarily daylit, and somewhat passive solar. The construction technique is all pre-cast concrete. The materials palette is fairly simple. There are no right angles in the building. They got very much into Rudolph Steiner’s anthroposophical design, one of the elements of which is that columns tend to be canted various ways and walls are canted in various interesting directions.

At another level there was an interesting collaboration between the energy expert and the artist. Colored pieces of metal on the atrium (one for each of the ten towers) bounce light down to a mirror array on the floor. The walls look green when the green metal panels are in the sun. As the sun moves across the sky, at different times of the year and different times of day, it may be yellow, blue, red, orange or pink, depending on the time of day and the time of year.

5.04 NMB Bank: circulation space with interior landscaping

The building wound up using one-tenth the energy per square foot of their previous building. It cost exactly the market average. But what interests me is more what happened with the bank. Because it so revolutionized their image, they went from being the number four bank of The Netherlands to number two. They have now moved into England and to the U.S. market.

My favorite feature in the whole building springs from it being passively ventilated. What happens in a masonry building with passive ventilation? Well, you get to hear every footstep and every conversation if you don’t have the normal hum, clank and rumble of an air handling system. They needed some way to get sound into the building, and they needed to get humidity into the building. So they did that with a cast bronze shape called a flowform. It is basically a stream splashing and gurgling in the hand rail. And it is pretty incredible to see bankers playing with the hand rails.

Now for NMB the most important number of all is what happened with their people. Absenteeism among bank employees is 15% less in this building than it was in their previous facility. Here is why that is important. Comparative cost of a building on an annual basis is $21 per square foot. Total energy costs are $1.81 per square foot. Meanwhile, office worker salaries are $130 per square foot. If I add in the equipment, benefits and insurance, the cost grows to over $200 a square foot a year.

Let’s flip that around. Ten times the rent or a hundred times the energy bill. A 1% gain in productivity is equivalent to eliminating the entire energy bill. What we discovered in a series of case studies is that companies that were driving down the energy use through daylighting, better lighting design, and better thermal comfort significantly raised worker productivity. And they weren’t just temporary effects.

Another one of those cases is the $50 million building in Lockheed Martin’s engineering production center. Twenty-six hundred employees work there. The building has a very unusual facade. The sloping panes are the view plane, and the vertical panes are light shelves. The floor to ceiling height is fifteen feet. The light shelf enables the light to bounce into the core of the building. In the center of the building is a lightrium. Now this is an integral daylighting device, and it remains a lightrium because at the time it was built, defense contractors were not allowed to have atriums. So this is a lightrium. The building saved half the energy per square foot of a Title 24 standard building, which at the time was the strictest energy code in the country. And the energy measures paid for themselves in four years. However, what Lockheed discovered was the rate of production among their employees increased by about 15%, which allowed them to competitively bid on a contract they would not have otherwise won, the profits from which paid for the entire building.

5.05 Lockheed 157: daylighting enhanced by central “litetrium”

5.06 Verifone World Distribution Center: existing tilt up concrete warehouse building

Another example is a tilt-up concrete warehouse, about as unexciting and unattractive a building type as you could imagine. It was built for Verifone, the folks who make the credit card verification keypads, as their worldwide distribution headquarters in Costa Mesa, California. It was an existing building. It had only three windows in it; because of seismic code, they couldn’t add any windows. No punctures in the concrete. All they could do was add daylighting through the roof. Now there are no electric lights on the remanufacturing floor. They work entirely in daylight. They use less than half the energy per square foot of a Title 24 building, the new Title 24.

The entire project was done for $39 per square foot, and in a five-month period. The most interesting number for Verifone is that absenteeism is 47% less among their employees than it was in their previous building. In fact, they have a new problem—they still have a hundred and eighty employees in the old building who are very angry.

5.07 Wal-Mart Eco-Mart: interior showing half of the store

Wal-Mart is another of our productivity studies. They pulled us in to help them create their Ecomart. We went through a lot of debate whether or not it would work with Wal- Mart. And we decided that any company that was building one store per working day at a hundred thousand square feet, someone had better talk to them.

One of the fights we had in the building was that our budget got cut for daylighting, and so BSW (the design architects) wound up being able to only daylight half the store. But within two months of operation, because of their Just-In-Time retail, they discovered that the daylit half had significantly higher sales than the conventional half. Wal-Mart is now funding almost more daylighting research than anyone else we have come across.

If we really want to get into the building as pedagogy, this is it: the Boyne River Ecology Center outside Toronto, Canada. It was originally designed as a stand-alone, self-powered building. Unfortunately the maintenance people have incapacitated portions of that. One of the systems that is doing well is the biological waste treatment system, in the center of the building. Raw sewage comes in at one end, and drinking water comes out at the other. School kids that visit here will go to the bathroom so that they can flush and come running and see themselves feed the system.

5.08 Montana State University, National ReSource Center: innovative designs, materials and construction techniques minimize environmental impact

Now that helped to inspire another building, which is maybe the one that’s pushing the furthest. It is the Montana State Green Laboratory Complex in Bozeman, Montana, which hopefully will get under construction in about 1998. Situated in lozenge shapes in front of the building are solar aquatic systems so that the building will treat all of its own waste products.

Using computational fluid dynamics and other energy modelling tools, our current estimate is that—the building being passive solar daylit, passively ventilated and passively cooled—we actually have a problem: we have discovered that in Bozeman there are six days of the year in which we’ll need heating. And so we’re trying to figure out what to do. We have designed in a series of radiant coils and are going to try to do it that way. So from an energy standpoint, this is a pretty good example.

Bozeman has an extraction economy—much like the rest of Montana. The by-products of that extraction are littering the landscape. Mining waste, agricultural waste, timber waste. And they import most of their building materials. So one of the goals of this project, both from an economic standpoint and from a research standpoint is that as many products as possible be produced within a three-hundred-mile radius of this building, and be developed in a way that they can then be sold after this building happens. Pliny Fisk helped to develop a fly ash-content concrete slab that’s extremely high strength, and lightweight, rastra panels, which are made with a compressed straw aggregate with high insulation value and are very sturdy. Maybe the most interesting product are gluelams from salvaged lumber. That is not all that outrageous until you discover that the adhesive is made from ba...