- 192 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

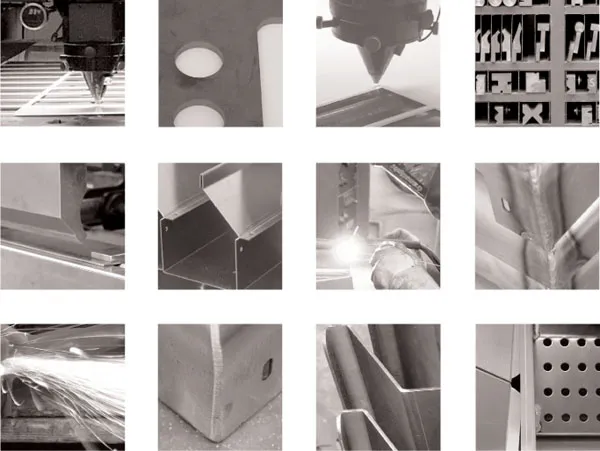

Fabrication

About this book

Packed with stunning images this is an indispensable visual guide illustrating and explaining current fabrication processes and material transformation. Providing a documentary of an eclectic range of fabrication techniques, this is the ideal reference for designers who wish to learn more about the materials and current technologies in material production available to them.

Featuring the work of 12 fabricators based in the UK, the case studies displayed range from manufacture of complex wire rope, the processes of metal spinning, large-scale composite casting, to computer controlled sheet steel fabrication. With a full knowledge of how the materials are transformed, this book provides readers with a greater ability to employ material processes for their own designs and to better understand material fabrication. This is a book that provides information on contemporary technology and design inspiration in abundance.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Sheet Metal

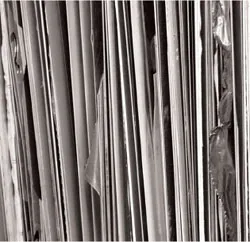

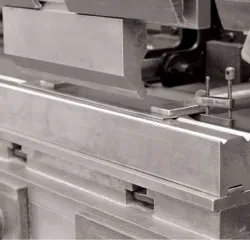

Fig 1.0 Sheet metal

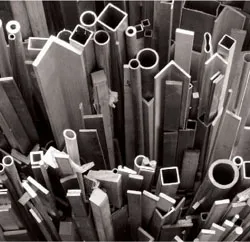

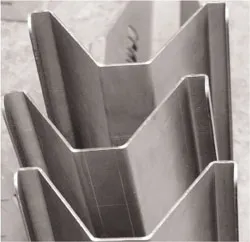

Fig 1.1 Metal sections

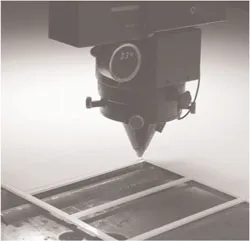

Fig 1.2 CNC laser

Sheet Metal

John Dent Engineering, Isleworth

Sheet Materials

Sheet materials come in various types, from mild steels to timber and plastics, and with varying degrees of thickness. If designers need sheet materials to be cut to size with precision, or if multiples are required, specialist fabricators provide the tools and expertise necessary for their production. Such fabricators will also have machines for folding sheet metal into complex shapes and will be able to finish (weld, polish, paint) products in a variety of ways.

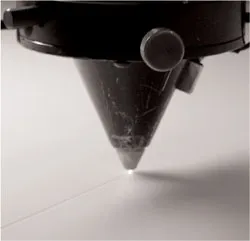

Laser Cutting

CNC (Computer Numerically Controlled) laser cutting is a process in which a shape is cut from sheet material using an intense laser beam that cuts by melting the material in the beam path. The process is particularly cost-effective for prototyping and short runs, since no physical tooling is needed and the process can accept almost any geometric shape. Lasers have interchangeable optics for different materials and depths of cut. Lasers work best on materials such as carbon steel - an alloy of iron and carbon (2%) or stainless steel - a corrosion resistant alloy of steel and chromium (10.5%). Metals such as aluminium and copper alloys are more difficult (slower) to cut by laser due to their ability to reflect the laser light as well as absorb and conduct heat - these materials require more powerful lasers.

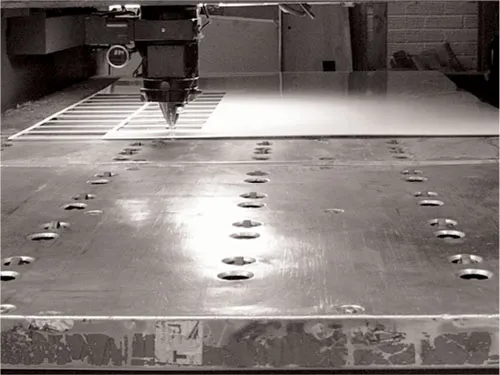

Fig 1.3 CNC cutting bench

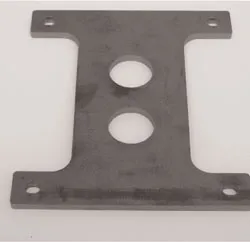

Fig 1.4 CNC Laser-cut, 8mm sheet steel

Fig 1.5 CNC laser-cut, 10mm sheet steel

Fig 1.6 CNC laser cutting 5mm plastic sheet

A laser can cut through a 1m long, 10mm thick, steel panel in around 30 seconds, but the thicker the steel the larger the curve that will form when cutting around corners. CNC lasers are housed in x/y/z-axis gantries that can be programmed to cut from CAD drawings like a large plotter. They are accurate to within 50 microns and parts remain flat.

Fig 1.7 John Dent Engineering

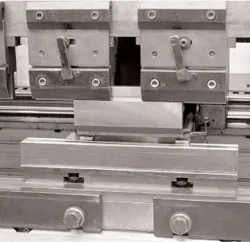

Fig 1.8 Press brake tool head

Fig 1.9 Tool head showing fold profile

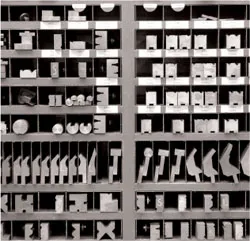

Fig 1.10 Tooling library

Maximum material cutting capacities are:

Mild steel - 12mm

Stainless steel (clean cut) - 3mm

Stainless steel (oxygen cut) - 12mm

Aluminium - 4mm

Brass - 2.5mm

Woods and Plastics - 30mm

Maximum sheet size - 3000mm × 1270mm

Maximum weight - 250kg

Folding and Finishing

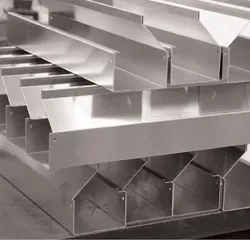

Once they have been cut into shape, malleable materials (i.e. those like sheet metal that can be folded without loss of structural integrity) can be formed into complex, three-dimensional shapes by multi-axis folding machine. An 80 tonne press brake can fold sheet metal up to 10mm thick.

Fig 1.11 Eight-axis, full CNC press brake

Fig 1.12 Sheet metal, cut and folded

Fig 1.13 Sheet metal, cut and folded

Fig 1.14 Hand finished folde...

Table of contents

- Front Cover

- Half Title

- Title Page

- Copyright

- Contents

- Author's Note

- Foreword

- Introduction

- 1 Sheet Metal

- 2 Softwood Timber

- 3 Glass-Reinforced Plastic

- 4 Tensile Steel

- 5 Steel Sections

- 6 Limestone

- 7 Terrazzo Concrete

- 8 Membrane Fabric

- 9 Float Glass

- 10 Tensile Yarns

- 11 Cast Metal

- 12 Spun Metal

- Glossary of Processes

- Company Information

- Sources

- Acknowledgments

- Authors

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Fabrication by Peter Silver,William McLean in PDF and/or ePUB format, as well as other popular books in Architecture & Architecture General. We have over one million books available in our catalogue for you to explore.