- 226 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Carpentry and Joinery 2

About this book

Carpentry and Joinery 2 is the second in a series of three books, which together provide an authoritative and thoroughly practical guide to carpentry and joinery for students following City & Guilds and CITB courses, NVQ candidates, and students working towards an Institute of Carpenters qualification. This book is also ideal for a wide range of amateur and professional woodworkers. Volume 2 builds on the fundamental knowledge introduced in volume 1, by covering more advanced topics and procedures, including machine tools. Essential 'back-up' topics are presented throughout the text to revise the key aspects covered in volume 1. The reader is shown how to apply this basic theory to actual carpentry and joinery practice in a highly illustrated, easily accessible text.The third edition has been fully updated in line with changes to the Building Regulations and current legislation, the third edition also incorporates developments in current best practice, with a comprehensive match to the latest qualifications in Wood Occupations.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1 Site setting-out

1.1 Linear measurement

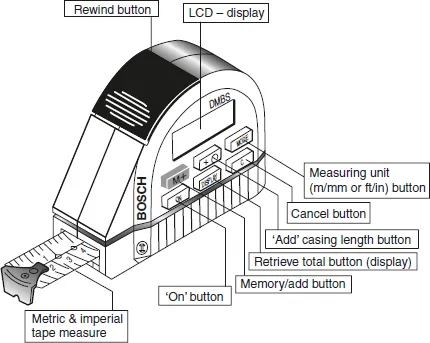

1.1.1 Measuring tapes

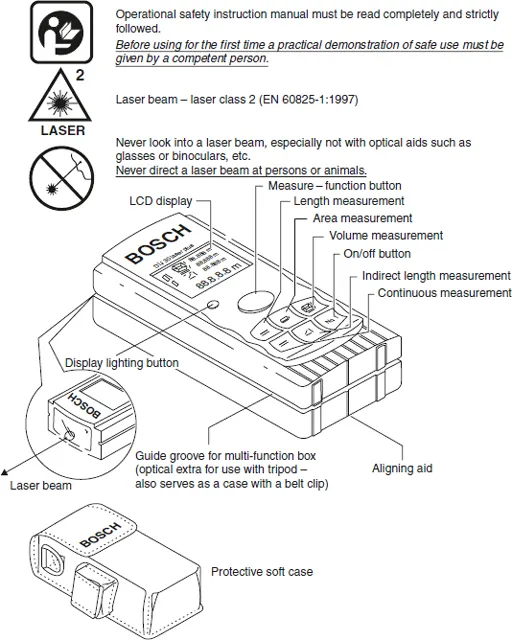

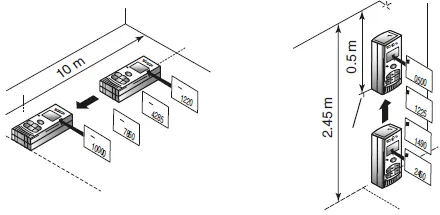

1.1.2 Laser digital distance metres (Fig. 1.4)

Safety (also see section 1.7.8)

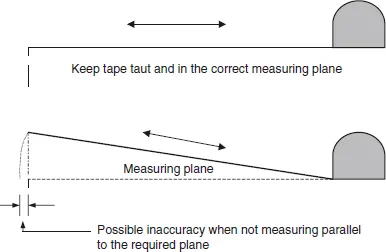

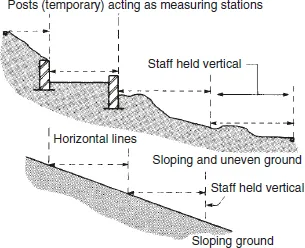

1.1.3 Sloping sites

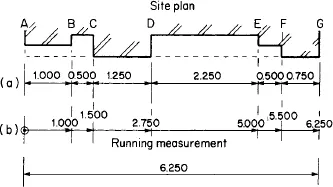

1.1.4 Transferring measurements

Table of contents

- Front Cover

- Half Title

- Title Page

- Copyright

- Contents

- Foreword by W. R. Rose

- Foreword by David R. Winson

- Preface

- Acknowledgements

- CHAPTER ONE SITE SETTING-OUT

- CHAPTER TWO FENCES AND HOARDING

- CHAPTER THREE FORMWORK (TEMPORARY WORK)

- CHAPTER FOUR TURNING PIECES AND ARCHED CENTRES UP TO 1-M SPAN

- CHAPTER FIVE GROUND FLOORS

- CHAPTER SIX SINGLE UPPER FLOORS

- CHAPTER SEVEN SINGLE TIMBER FLAT ROOFS

- CHAPTER EIGHT ROOFS OF EQUAL PITCH

- CHAPTER NINE PARTITIONS (NON-LOAD BEARING)

- CHAPTER TEN SCAFFOLDING

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app