![]()

Chapter 1 | The Manufacturing Industry |

Summary

When you have read this chapter you should be able to:

- Understand what is meant by the term ‘manufacturing’

- Appreciate the role of our manufacturing industries as a means of national wealth creation

- Appreciate the range of products produced by UK manufacturers and their importance in terms of national wealth creation and employment opportunities

- Understand the meaning of ‘scale of production’

- Understand the meaning of such terms as ‘gross domestic product’ (GDP) and ‘gross national product’ (GNP)

- Understand the meaning and importance of the ‘balance of trade’

- Understand the factors affecting the location of manufacturing industry

- Recognize the key stages of production

- Recognize the scales of production

- Recognize a typical production system.

1.1 What is Manufacturing?

Manufacturing can be defined as the conversion of raw materials into useful articles by means of physical labour or the use of power driven machinery.

In prehistoric times, cave dwellers found that if a piece of flint stone was struck with another stone the flint could be turned into a sharp spear head or arrow head. They took the flint as their raw material and, by means of physical labour, converted it into something useful. They were manufacturing. By converting a useless piece of flint into a useful tool, they made it easier to defend themselves and to hunt for food in order to provide the tribe with its next meal.

Manufacturing has come a long way since then. Today, although there are still many skilled craftsmen who make things by hand, the manufacturing industries that are of significant economic importance to the nation are usually large concerns employing hundreds and in some cases thousands of people. They need large buildings, complex machinery and major investments of capital. They increasingly market and sell their products not just in one country but around the world.

Manufacturing as we understand it today began in what is called the industrial revolution. The UK was the first nation to undergo the change from a largely agricultural economy to full-scale industrialization. The foundations for this industrial revolution were laid in the seventeenth century by the expansion of trade, the accumulation of wealth and social and political change. This was followed in the eighteenth century by a period of great discoveries and inventions in the fields of materials, transportation (better roads, canals and railways), power sources (steam), and in the mechanization of production.

The momentum for change originated with the mechanization of the textile industries (spinning and weaving) which, in turn, resulted in these cottage industries being replaced by the factory system. This increased the need for machines and the power units that would drive these machines more reliably than water wheels that came to a halt during periods of drought. The mechanical engineering industry was born out of the demand for machines and motive power sources of ever increasing size and sophistication. Fortunately, at this time, a series of inventors and engineers in the UK developed the early steam pumping engines used in mines into ‘rotative’ engines suitable for driving machines. The transportation of raw materials and finished goods was transformed by the development of the railways and by steam powered boats capable of crossing the oceans of the world. At last, the manufacturing industries and the transportation of their goods were free from the vagaries of the weather and the limitations of horse drawn vehicles.

Mechanization and reliable power sources enabled UK manufacturers to turn out more goods than the UK alone needed. These surplus goods were sold abroad, pointing the way to the worldwide trade in all sorts of manufactured goods that we take for granted today. The ships taking the products manufactured in the UK to other countries brought raw materials from those countries back to the UK to sustain further manufacture.

Manufacturing is a commercial activity and exists for two purposes:

- To create wealth. There is no point in investing your money or other people’s money in a manufacturing plant unless the return on the investment is substantially better than the interest that your money could earn in a savings account.

- To satisfy a demand. There is no point in manufacturing a product for which there is no market. Even if there is a market (a demand), there is no point in manufacturing a product to satisfy that demand unless that product can be sold at a profit.

We have already defined manufacturing as the conversion of raw materials into useful articles by means of physical labour or the use of power driven machinery. When this conversion takes place there is value added to the raw materials. This increase in value represents the creation of wealth both for the owners of the manufacturing enterprise itself and the nation as a whole. Manufacturing makes a vital contribution to the local and national economies of the UK. Prior to the Second World War the UK was still a major manufacturing country exporting a wide range of products all over the world. This predominant position in manufacturing and global trade has diminished rapidly since the Second World War with the rapid development of industrial economies in Asia and the Far East where labour is plentiful and cheap, also manufacturing and the marketing of manufactured goods has become global. Throughout the world, national companies have merged into multi-national companies with the financial strength and resources to buy their raw materials in bulk and establish factories wherever suitable labour is most plentiful and cheapest.

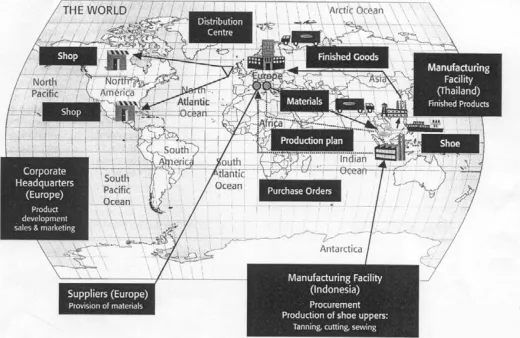

An example of industrial globalization is shown in Fig. 1.1. In this example a leather footwear product is designed, developed and marketed in Western Europe. The hides for the leather are sourced in Eastern Europe. The hides are tanned, cut and sewn to make the uppers in Indonesia and then sent to Thailand to be assembled to the soles and finished. The finished shoes are sent in bulk to a distribution warehouse in the UK before being individually packed and despatched to retail shops throughout the world. Globalization has largely come about through the ease of modern communications via e-mail and the Internet. Also, the use of computer numerically controlled (CNC) machines enables high quality manufacturing to be achieved with relatively low cost, low skilled labour.

Figure 1.1 Global manufacture.

Test your Knowledge 1.1

- Describe briefly what is meant by ‘manufacture’.

- State the main purposes of manufacture.

- Explain what is meant by ‘global manufacture’.

1.2 The Main UK Manufacturing Sectors

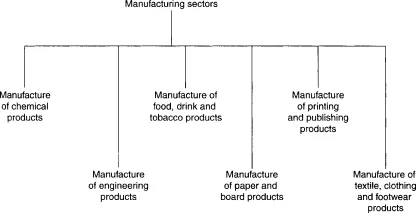

Despite its now diminished role, manufacturing industry is still vital to the British economy. The income generated by manufacturing and the hundreds of thousands of jobs which the manufacturing industry creates is still essential if the UK is to sustain an acceptable level of employment and pay its way in the world. Increasingly, however, we are becoming dependent on the income generated by the service industries of banking, insurance and in-tourism to make good the shortfall in the balance of trade (see Section 1.8.3). Manufacturing takes many different forms. To make the industry easier to study, we will break it down into six main sectors. These sectors are shown in Fig. 1.2.

Figure 1.2 Main UK manufacturing sectors.

Let’s now look at each of these sectors in turn in order to find out what it is that they actually produce.

1.3 The Chemical Industry

Chemical manufacturing covers a range of different activities, starting with the manufacturing of the basic chemicals (feed stocks) from raw materials. These feed stocks are then used by other parts (subsectors) of the industry in more complicated processes. Chemicals are defined as being either organic or inorganic.

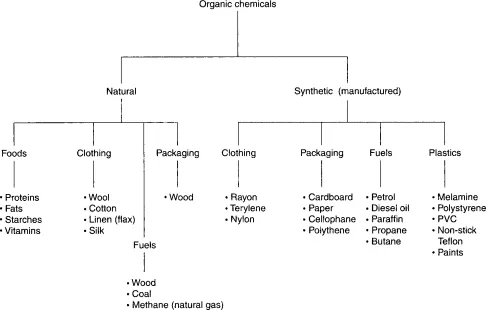

Organic chemicals consist of complex carbon compounds. Carbon forms more compounds than any other chemical. It forms the complex long chain molecules found in animal and plant life (hence the name organic chemicals). Carbon also forms the long chain molecules found in the byproducts of the fossil fuel industries and are widely used in the manufacture of plastic materials. We ourselves are built from carbon chains. Some organic chemical substances upon which we depend are shown in Fig. 1.3. As you will see, many organic chemicals are substances that occur naturally. Other organic chemicals are synthetic and are manufactured from a variety of raw materials.

Figure 1.3 Some organic chemicals.

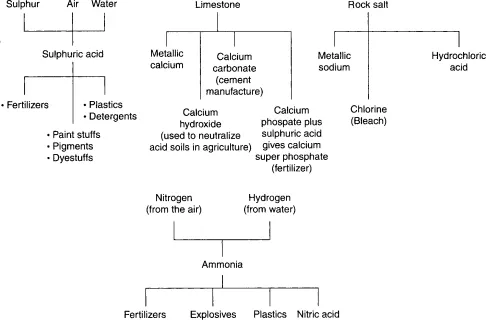

Inorganic chemicals are all the substances that are not based upon complex carbon chain compounds. For example chemicals made from mineral deposits such as limestone, rock salt, sulphur, etc., as shown in Fig. 1.4.

Figure 1.4 Some inorganic chemicals.

Both organic and inorganic chemicals are manufactured and used in very large quantities, and this is reflected in the size of the plants in which they are made. In addition, many chemicals, if they are not properly handled, can be extremely dangerous. Computerized and automated processes are widely used in chemical engineering to avoid the possibility of catastrophic accidents caused by human error. The size of the factories, the complexity of the manufacturing processes and the need for stringent safety precautions means that the whole business is very expensive, with the result that there are only a few, very large companies that dominate the sector.

In the UK, the chemical industry makes products such as plastics, fertilizers, paints, adhesives, explosives, synthetic fibres, and provide gases such as oxygen, acetylene, nitrogen, argon, and carbon dioxide for industry and gases such as oxygen, and anaesthetics for hospitals. Some chemical manufacturing companies specialize in domestic and health care products. These range from medicines and disinfectants to cleaning materials and polishes. The companies may be UK owned or they may be the UK branches of international (global) companies.

Another factor which ensures that the chemicals manufacturing sector is dominated by a handful of large operators is that they have to put a lot of money every year into research and development (R&D). Sometimes that research...