- 180 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Space Grid Structures

About this book

A space frame is a three-dimensional framework for enclosing spaces in which all members are interconnected and act as a single entity. A benefit of this type of structure is that very large spaces can be covered, uninterrupted by support from the ground.

John Chilton's book provides an up-to-date assessment of the use of space grid structures in buildings by reviewing methods of construction, various systems available and detailed studies of the use of space grids in modern buildings. The technical level is aimed at professional and student architects and engineers worldwide and it also serves as a useful construction manual.

John Chilton is an engineer, currently teaching architectural students at Nottingham University where he is a senior lecturer. He has also undertaken considerable research in this field.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1 Early Development of Space Grids

Architects and engineers are always seeking new ways of solving the problem of space enclosure. With the industrialization and development of the modern world there is a demand for efficient and adaptable long-span structures. Space grid structures are a valuable tool for the architect or engineer in the search for new forms, owing to their wide diversity and flexibility. Before entering into a discussion of the design and use of space grids in the late twentieth century, it is useful to look back at the early use of three-dimensional structures.

Until the middle of the eighteenth century the main construction materials available to architects and engineers were stone, wood and brick. Metals, being in relatively short supply, were used mainly for jointing of the other materials. Of the widely available materials, stone and brick are strong in compression but weak in tension. Thus they are suitable for three-dimensional structural forms such as domes and vaults. Impressive feats of vaulting were achieved by medieval masons but the largest span masonry domes, St Peter’s Basilica in Rome (1588–93) and Santa Maria del Fiore in Florence (1420–34) are both approximately 42 m diameter at the base.1 Good quality timber has strength in tension and compression but is naturally available only in limited lengths and with limited cross-section. For large-scale three-dimensional structures jointing of timber becomes a major problem. Nevertheless, the Todai-ji temple at Nara in Japan, the largest historic timber building in the world, is 57 m by 50 m and 47 m high. The present building dates from 1708 and replaces the original, even larger, structure which was destroyed by fire. Although these materials were used to produce impressive large-scale structures, the spans were limited and the construction heavy. However, with the Industrial Revolution came the wider production of iron and then steel, high-strength materials that permitted the construction of more delicate structures of longer span or greater height. At approximately the same time, mathematical techniques were being developed to describe and predict structural behaviour and understanding of the strength of materials was advancing rapidly. Equally, with the advent of the Railway Age and the industrialization of commodity production came an increasing demand for longer span structures for bridges, stations, storage buildings and factories. With the wider availability of iron and steel and the demand for larger spans, there came a period of development of new structural forms, initially a multiplicity of different truss configurations and eventually three-dimensional space grids.

Many structural forms including most space grid assemblies are modular. The concept and efficiency of modular building construction was dramatically illustrated, almost 150 years ago, by the design, fabrication and assembly of the metal framework of the Crystal Palace in Hyde Park, London, for the Great Exhibition of 1851. The whole process, from the submission of the tender by Fox Henderson & Co. and Joseph Paxton to the possession of the completed building, was accomplished in approximately six months – a feat that would probably tax the abilities of today’s construction industry.

Landmark structures such as the Eiffel Tower in Paris constructed from wrought iron between 1897 and 1899, bear witness to the stability and durability of modular three-dimensional metal construction. The tower, built as a symbol for the centenary celebration of the French Revolution, and conceived as a temporary structure, has already survived over 100 years. Sadly, the magnificent 114 m span Galerie des Machines by Contamin and Dutert, built at the same time adjacent to the tower, has not. Such structures demonstrated the possibilities for the use of iron and steel in high-rise and long-span buildings and challenged the ingenuity of architects and engineers to discover new and more efficient ways for their construction.

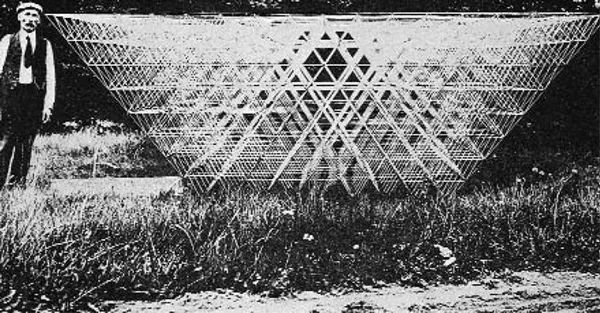

Probably the earliest examples of what we now commonly call space frames or space grids (light, strong, three-dimensional, mass-produced, modular structures) were developed by the inventor of the telephone, Alexander Graham Bell (1847–1922). In the first decade of the twentieth century he experimented with space trusses composed of octahedral and tetrahedral units (Figure 1.1). In his article on kite construction in the National Geographic Magazine,2 in 1903, Bell commented:

1.1

Early experimental space grid structure developed by Alexander Graham Bell in the first decade of this century

Of course, the use of a tetrahedral cell is not limited to the construction of a framework for kites and flying-machines. It is applicable to any kind of structure whatever in which it is desirable to combine the qualities of strength and lightness. Just as we can build houses of all kinds out of bricks, so we can build structures of all sorts out of tetrahedral frames and the structures can be so formed as to possess the same qualities of strength and lightness which are characteristic of the individual cells.

As can be seen from this quotation, Bell appreciated the dual properties of high strength and light weight exhibited by the rigid three-dimensional tetrahedral forms and incorporated them into many of his projects. One of the first steel space grid structures, using cast nodes and tubular members, the observation tower at Beinn Bhreagh, USA, was constructed by Bell in 1907.

Despite Bell’s development of lightweight three-dimensional space trusses early in the century, they were not used in architecture until the introduction of the MERO system, in 1943. This was the first space grid system widely available commercially and was developed in Germany by Dr Ing. Max Mengeringhausen (1903–88). Using what is still probably the most common method of space truss construction, the system consists of individual tubular members connected at ‘ball’-shaped node joints. The aesthetic appeal and popularity of this system has endured to the present day, as confirmed by the many alternative tube and ball systems now available.

An alternative popular method of constructing double-layer grids uses prefabricated modules. In the UK, during the 1950s, Denings of Chard developed the Space Deck system, based on bolting together prefabricated steel pyramidal modules (1.22 m × 1.22 m in plan and 1.05 m or 0.61 m deep respectively). With only slight modifications to module dimensions and materials, Space Deck has been widely and successfully used for roof and floor structures ever since. The system is described in detail in Chapter 3. A similar module, with the same plan dimensions but overall depth of 600 mm, was adopted for roof and floor construction in the Nenk modular building system.3 The Nenk system was developed by the former Ministry of Public Building and Works in the UK in collaboration with Denings and was used in the construction of army barrack blocks in the early 1960s. It could span 12.2 m (40 feet) with normal floor loads and 26.8 m (88 feet) with normal roof load. Space grids were used to allow freedom of column location and space planning on the floor below. Precast concrete floor slabs, set on preformed strips of polystyrene or polyurethane, were used within the square upper grid of the modules to form the floor plates.

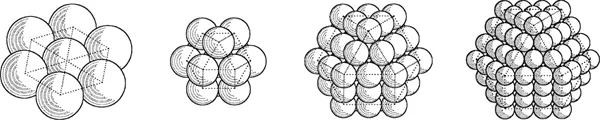

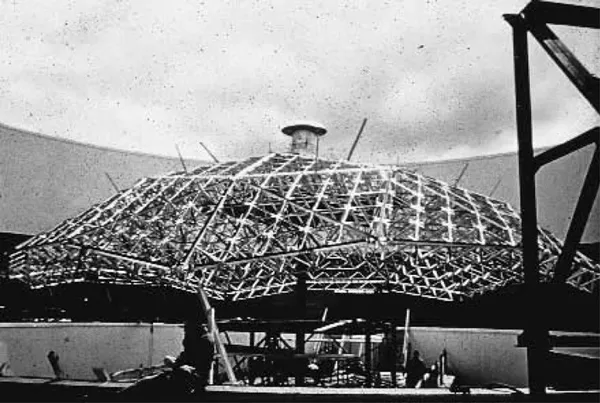

During the 1950s and 1960s, space grid systems were proliferating all over the world as architects explored the relatively new aesthetic of the modular grid and engineers experimented with alternative jointing systems, materials and configurations. In the USA, Richard Buckminster Fuller (1895–1981), following his study of the closest packing of spheres, developed the Octet Truss system.4,5,6 The name Octet Truss derives from the octahedron-tetrahedron geometry formed by the lines linking the centres of spheres packed together in a continuum so that each sphere is surrounded by twelve more in close contact (see Figure 1.2). Members of the space grid then follow these lines. The Ford Rotunda Building, Ford River Rouge Plant, Dearborn, Michigan, constructed in 1953, used aluminium Octet Truss grids to form the faces of a 28.4 m diameter geodesic dome weighing only 8.5 tonnes (Figure 1.3). This space grid is of ‘nodeless’ construction as the X-shaped ends of the members allow them to be bolted directly to each other at the intersections without the use of a separate node component. An exhibition of Buckminster Fuller’s work at the Museum of Modern Art, New York, in 1959, featured a 1.22 m deep Octet Truss structure 10.7 m wide and 30.5 m long (consisting of two cantilevers of 18.3 m and 12.2 m) made from 51 mm diameter aluminium tubes.

1.2

Close-packing of spheres as studied by R. Buckminster Fuller. (Drawing: John Chilton)

1.3

Dome of the Ford Rotunda Building, Dearborn, Michigan, USA constructed using 20 960 members assembled into Octet trusses as developed by R. Buckminster Fuller

Konrad Wachsmann (1901–80) was appointed in 1959 to develop a space grid system for large span aircraft hangars, for the United States Air Force. The brief demanded great flexibility in construction, geometry and bu...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright

- Contents

- Preface

- Acknowledgements

- 1. Early Development of Space Grids

- 2. Space Grid Geometry – Thinking in Three Dimensions

- 3. Materials and Systems

- 4. Design and Construction

- 5. Case Studies

- 6. Deployable, Foldable and Retractable Space Grids

- 7. Future Developments

- Appendices

- Further Reading

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Space Grid Structures by John Chilton in PDF and/or ePUB format, as well as other popular books in Architecture & Architecture Methods & Materials. We have over one million books available in our catalogue for you to explore.