- 272 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Six Sigma

About this book

There are a number of distinctive features of this book that makes it different from other on Six Sigma.

It recognizes that there are two diametrically opposing views expressed on Six Sigma, those that are strongly in favour, and those that are not, for various reasons. The book deals, head on, with the principle reasons for such hostility. It cuts through the hype associated with the brand name. It proposes simple remedies for certain defined frailties in the standard approach, particularly those related to the Sigma Measure that provides the brand name for the Six Sigma breakthrough strategy.

The book is highly supportive of the Six Sigma continuous improvement process, provided it is tailored to the needs and expectations of a particular organization. The commitment and active participation of top management is emphasized, to ensure the necessary change in culture and priorities demanded, in most organizations.

Practical guidance is given in the setting up, operating and developing the project by project approach across an organisation. The book also covers how to equip a critical mass of members in an organization with the core workforce competencies required to get the desired results.

The book covers the realities of applying Six Sigma in a range of functions within an organization and also to various types of organizations from the manufacturing sector to commerce and public service. It demonstrates how statistical thinking, coupled with the application of technical and operational knowledge of processes and focus provided by Six Sigma, can considerably enhance quality, competitiveness, effectiveness and efficiency.

Statistical process control is a tool, which enables both manufacturers and suppliers to achieve control of product quality by means of the application of statistical methods in the controlling process. This book gives the foundations of good quality management and process control, including an explanation of what quality is, and control of conformance and consistency during production. The text offers clear guidance and help to those unfamiliar with either quality control or statistical applications and coves all the necessary theory and techniques in a practical and non-mathematical manner. This book will be essential reading for anyone wishing to understand or implement modern statistical process control techniques.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Chapter 1

What is Six Sigma?

Six Sigma is the most important initiative General Electric has ever taken

Jack Welch

Six Sigma in Perspective

Six Sigma focuses on establishing world-class business-performance benchmarks and on providing an organizational structure and road-map by which these can be realized. This is achieved mainly on a project-by-project team basis, using a workforce trained in performance-enhancement methodology, within a receptive company culture and perpetuating infrastructure. Although particularly relevant to the enhancing of value of products and services from a customer perspective, Six Sigma is also directly applicable to improving the efficiency and effectiveness of all processes, tasks and transactions within any organization. Projects are thus chosen and driven on the basis of their relevance to increased customer satisfaction and their effect on business-performance enhancement through gap analysis, namely, prior quantitative measurement of existing performance and comparison with that desired.

Six Sigma, in current business usage, has a dual meaning. Six Sigma provides, on the one hand, a world-class standard or benchmark for product and service characteristics and for process parameters. On the other hand, Six Sigma refers to the structured process itself aimed at achieving this standard of near perfection. These two meanings contrast with the precise statistical meaning of the term.

Success in Six Sigma is dependent on active senior management leadership and mentoring, an established infrastructure including, the so-called ‘judo-like black and green belts’, a continuing project focus on ‘bottom line’ opportunities and results, with established teams trained in using a structured approach and methodology to achieve positive results. Six Sigma does not normally require significant capital expenditure other than for investment in the training and development of the participants in the process. It does, however, require long-term commitment from management in the ongoing process of continual improvement through active interest, support and review and the provisioning of appropriate resources. However, financial benefits should begin to be experienced with the completion of the first set of projects undertaken. Results from organizations committed to the Six Sigma initiative indicate that the financial benefits make a very significant effect on the ‘bottom line’.

Principal Facets of Six Sigma

What is it about the term Six Sigma that evokes such extreme views?

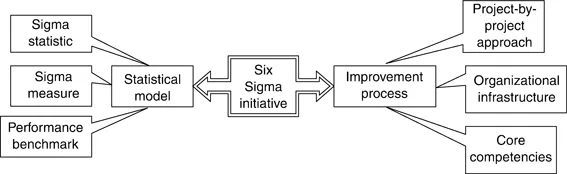

Much of the reason probably lies in the confusion surrounding its conceptual meaning and differences in interpretation of this multifaceted expression. In this respect, it is essential to clearly distinguish between Six Sigma – the statistical model, on the one hand, and Six Sigma – the improvement process, on the other. The statistical model comprises three principal constituents: the standard sigma statistic, the Six Sigma metric (measure) and the Six Sigma performance benchmark. The Six Sigma improvement process is also made up of three essential elements: its project-by-project approach, Six Sigma organizational infrastructure and its development of core workforce Six Sigma competencies. Figure 1.1 illustrates these principal facets of the Six Sigma business initiative. Each aspect is now discussed.

Figure 1.1 Principal facets of the Six Sigma business initiative

Six Sigma: the Statistical Model

The Six Sigma statistical model is intended, by its originators, to serve a triple purpose. This is to provide: a universal performance metric, or measure, that can be applied to any product, process or service regardless of its relative complexity; a world-class performance benchmark; and the marketing name for the Six Sigma improvement initiative. The statistical model is essentially made up of three elements as indicated in Figure 1.1. These are the:

- Sigma statistic. This refers to the universally used statistic, the statistical measure of variability, termed standard deviation, and called ‘sigma’. It forms the basis of the statistical model.

- Sigma measure. This Sigma is not the same as, but is indirectly related to, sigma and provides a numerical performance measuring scale.

- Performance benchmark. A Sigma value of 6, as used by many Six Sigma practitioners, represents a so-called world-class performance standard of 3.4 defects per million opportunities.

A discussion of the Six Sigma statistical model is considered from three viewpoints: overall appreciation level; technical level; and statistical level. Those readers who purely wish to have a general impression of the essential value and application of the Six Sigma statistical model will probably contain themselves to the overall appreciation level discussion in this chapter. However, it is imperative that those who are, or intend to be, associated with Six Sigma in any ‘hands-on’, or influential, sense read also the critique, discussion and response at the technical level in Chapter 7. Such readers may also consider it beneficial to consider, and reflect upon, the statistical issues covered and recommendations made in Chapter 8. This will enable them to take the appropriate countermeasures and make the improvements necessary in the original Six Sigma statistical model (that is in widespread use) to improve its efficiency and effectiveness in a diagnostic sense in their area of operation.

Appreciation-Level Discussion

The statistical model provides the marketing name for the Six Sigma improvement initiative. The originators of the Six Sigma initiative use a unit of measurement, a ‘Sigma’, to measure performance, the higher the number of Sigma the better the performance. For example, a 6 Sigma process is rated better than a 5 Sigma one.

An advantage of the Sigma measure is its simplicity and practicality. This appeals to all those who do not wish to get too embroiled in statistical niceties, but just want a simple readily understandable scale of performance measurement. The fact that 6 Sigma denotes something better than 5 Sigma and that 5 Sigma is better than 4 Sigma, and so on makes good practical sense to a number of people and they are quite happy to run with it.

The relationship between Sigma value and faults per million opportunities and equivalent percentage yield, used in standard Six Sigma practice, is shown in Table 1.1. A more detailed table is shown in Table 7.2.

Table 1.1 Relationship between Sigma value and faults per million opportunities and equivalent yield

Six-Sigma Sigma value | Faults (or events) per million opportunities | Yield (%) |

1 | 691462 | 30.85 |

2 | 308538 | 69.146 |

3 | 66807 | 93.319 |

4 | 6210 | 99.379 |

5 | 233 | 99.9767 |

6 | 3.4 | 99.99966 |

Many quotes are made to appeal in the emotive sense to emphasize the need for improvement in the Sigma value from current values to world-class values. Two examples are given in Table 1.2.

Table 1.2 Effect of Sigma value on expectations of different everyday event results

Process Sigma value | Expectation of | |

time without electricity per month | aircraft landing/takeoff incidents in each direct return flight | |

2 | 207 h | 8 per 10 flights |

3 | 45 h | 24 per 100 flights |

4 | 4 h | 25 per 1000 flights |

5 | 9 min | 9 per 10 000 flights |

6 | 8 sec | 12 per million flights |

In the United States of America, such quotes abound. For activities taking place at Sigma levels of between 3 and 4 there would be some 50 newborn babies dropped per day, 5000 incorrect surgical procedures per week, 20 000 lost articles of mail per hour, and so on.

It has been said that a computer is ‘a device to turn a clerical error into a corporate disaster’. There may be good reasons for this statement when one considers that there is said to be, on average, one software error in every 55 lines of computer program. This equates to a Sigma line value of between 3 and 4. Think of the effect of this on the air traffic control system in the United Kingdom, where at Swanwick alone there are more than 2 000 000 lines of computer code. Compound this with computer upgrades, staffing problems and the fact that flight controllers complain that they have difficulty in distinguishing between figures and letters on screen. Is it surprising that there were 3500 h of flight delays registered in one recent week? On the understanding that the amount of software is doubling every 18 months or so, and that, historically, the defect density is remaining virtually constant, this inevitably leads one to a very pessimistic conclusion. In the absence of some form of intensive improvement initiative such as Six Sigma, the computer industry and its customer base are likely to continue spawning known and avoidable failures such as those mentioned. If this initiative is not taken the computer will continue to be ‘a device that turns a clerical error into a corporate disaster’!

Six Sigma: the Improvement Process

Pro...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright

- Contents

- Preface

- 1. What is Six Sigma?

- 2. Why Should Organizations Implement Six Sigma?

- 3. How does Six Sigma Compare with other Improvement Initiatives?

- 4. How can Six Sigma Achieve the Greatest Impact on Business Performance?

- 5. What Competencies are Required to Drive Six Sigma?

- 6. What are the Options for Tailoring and Implementing Six Sigma?

- 7. Is the Six Sigma Statistical Model Technically Sound?

- 8. Which Sigma Should be Used?

- Appendix A: Relationship Between Critical-To-Quality Characteristics and System Performance

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Six Sigma by William Truscott in PDF and/or ePUB format, as well as other popular books in Business & Business General. We have over one million books available in our catalogue for you to explore.